Share

Share

Print

Print

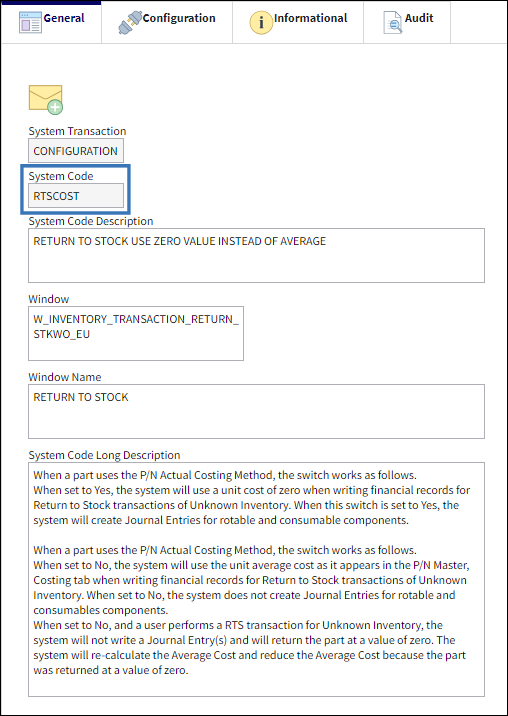

RTSCOST - Use Value Of Zero Instead Of Average For RTS

Use Value Of Zero Instead Of Average For RTS

Affected Windows: w_inventory_transaction_adjustment, w_inventory_transaction_return_non_eu, dw_system_tran_config_eu

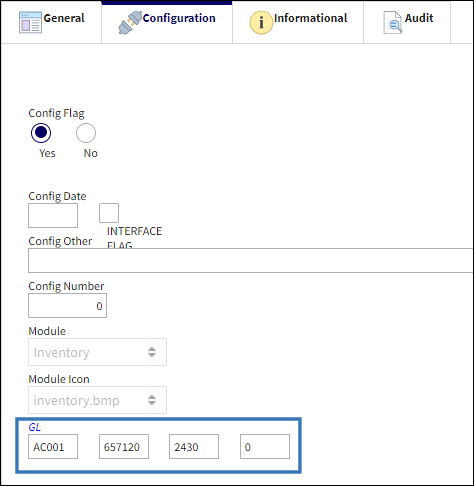

GL Field:

Enter the G/L Account Code that will be impacted when Return To Stock transactions of unknown Inventory are executed.

Regardless of whether the switch is set to Yes or No, if the G/L field is not populated no transactions will be recorded.

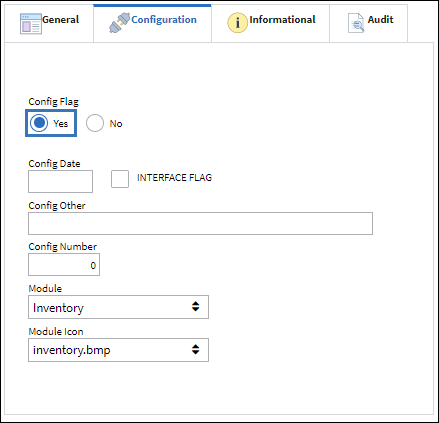

Switch Set to Yes:

When a part uses the P/N Actual Costing Method, the switch works as follows.

When set to Yes, the system will use a unit cost of zero when writing financial records for Return to Stock transactions of Unknown Inventory. When this switch is set to Yes, the system will create Journal Entries for rotable and consumable components.

When set to Yes, and a user performs a RTS transaction for Unknown Inventory, the system will write a Journal Entry(s) and will not re-calculate the average cost. The system applies the current Average Cost to the returned part from the P/N Master.

The Return to Stock button, via Inventory/Update/ Inventory Transaction, allows for the adjustment of inventory quantities.

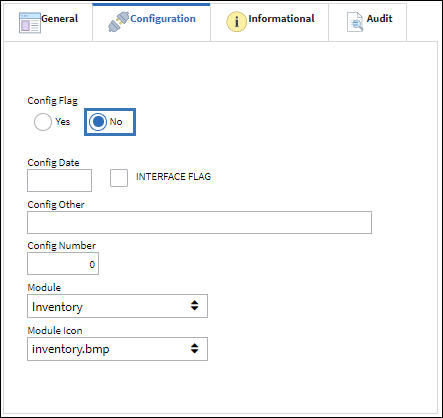

Switch Set to No:

When a part uses the P/N Actual Costing Method, the switch works as follows.

When set to No, the system will use the unit average cost as it appears in the P/N Master, Costing tab when writing financial records for Return to Stock transactions of Unknown Inventory. When set to No, the system does not create Journal Entries for rotable and consumables components.

When set to No, and a user performs a RTS transaction for Unknown Inventory, the system will not write a Journal Entry(s) and will return the part at a value of zero. The system will re-calculate the Average Cost and reduce the Average Cost because the part was returned at a value of zero.

Note: If there is no current inventory for the RTS part and the part is being returned to stock with a cost of zero, then the Average Cost of that part will be recalculated to zero. The calculation will take into account the Average Cost of the inventoried parts along with the zero cost of the RTS transaction.

Share

Share

Print

Print