Share

Share

Print

Print

MANUALS > Inventory > Inventory Switches > INVOWNICON - Override Consigned Parts Icon

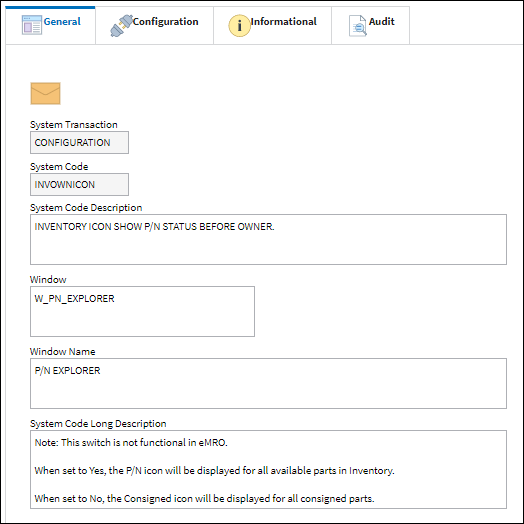

INVOWNICON - Override Consigned Parts Icon

Override Consigned Parts Icon

Affected Window: w_pn_explorer

Note: This switch is not functional in eMRO.

Share

Share

Print

Print