Share

Share

Print

Print

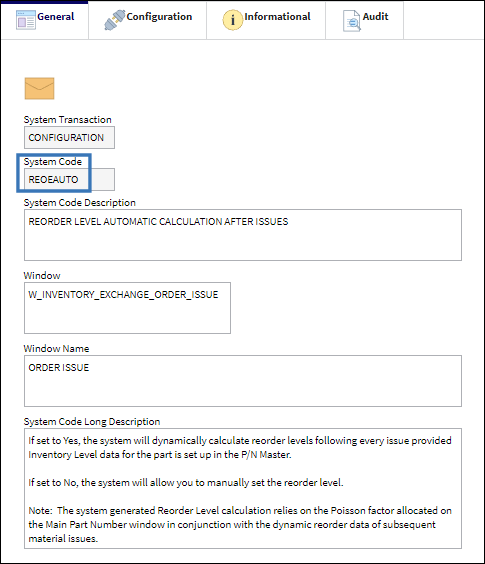

REOEAUTO - Reorder Level Automatic Calculation After Issues

Reorder Level Automatic Calculation After Issues

Affected Windows: w_inventory_exchange_order_issue, w_inventory_one_step_transfer, w_inventory_rental_order_issue, w_inventory_transaction_adjustment, w_inventory_transaction_break_kit, w_inventory_transaction_break_kit_ctl, w_inventory_transaction_break_kit_item, w_inventory_transaction_express_issue, w_inventory_transaction_manual_issue, w_inventory_transaction_picklist_issue, w_inventory_transaction_picklist_issue, w_inventory_transaction_return_of_loan, w_inventory_transaction_return_to_vendor, w_inventory_transaction_scrap, w_inventory_transaction_tool_check_out, w_physical_count_adjustment_sel, w_co_order_detail_eu, w_co_order_header_eu, w_co_order_header_eu, w_order_auto_print_sel, w_to_order_detail_eu, w_pn_inventory_level_eu

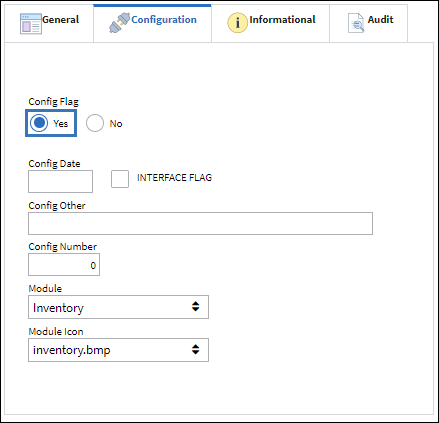

Switch Set to Yes:

When set to Yes, the system will dynamically calculate re-order levels following every issue.

Note: Switch REOEAUTO functionality relies on the Inventory Level data in the Part Number Master set up for the part. Review the P/N Inventory Level set up steps below.

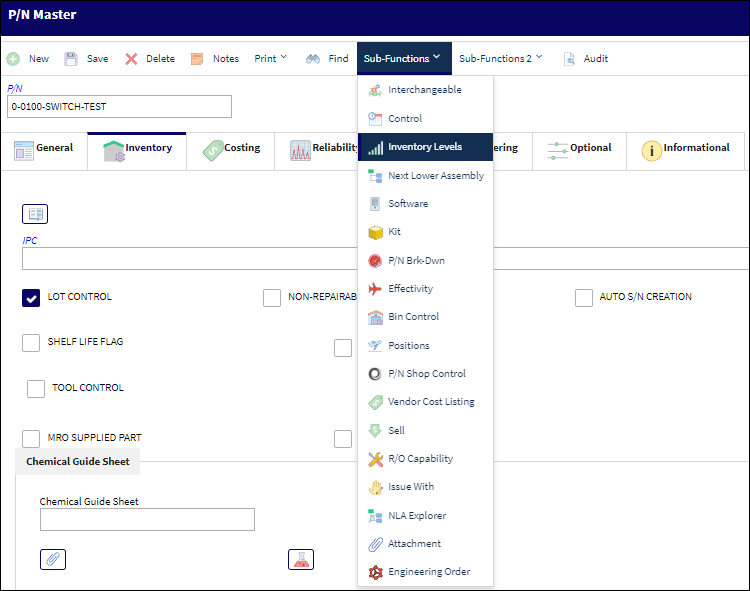

Follow menu pathway Settings/Update/P/N and once the part is populated, access the Inventory Level data for the part from the drop-down menu under the Sub-Functions button.

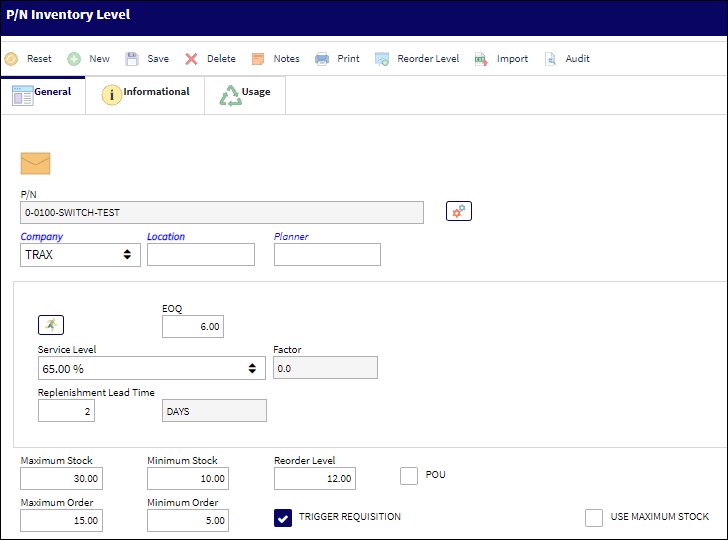

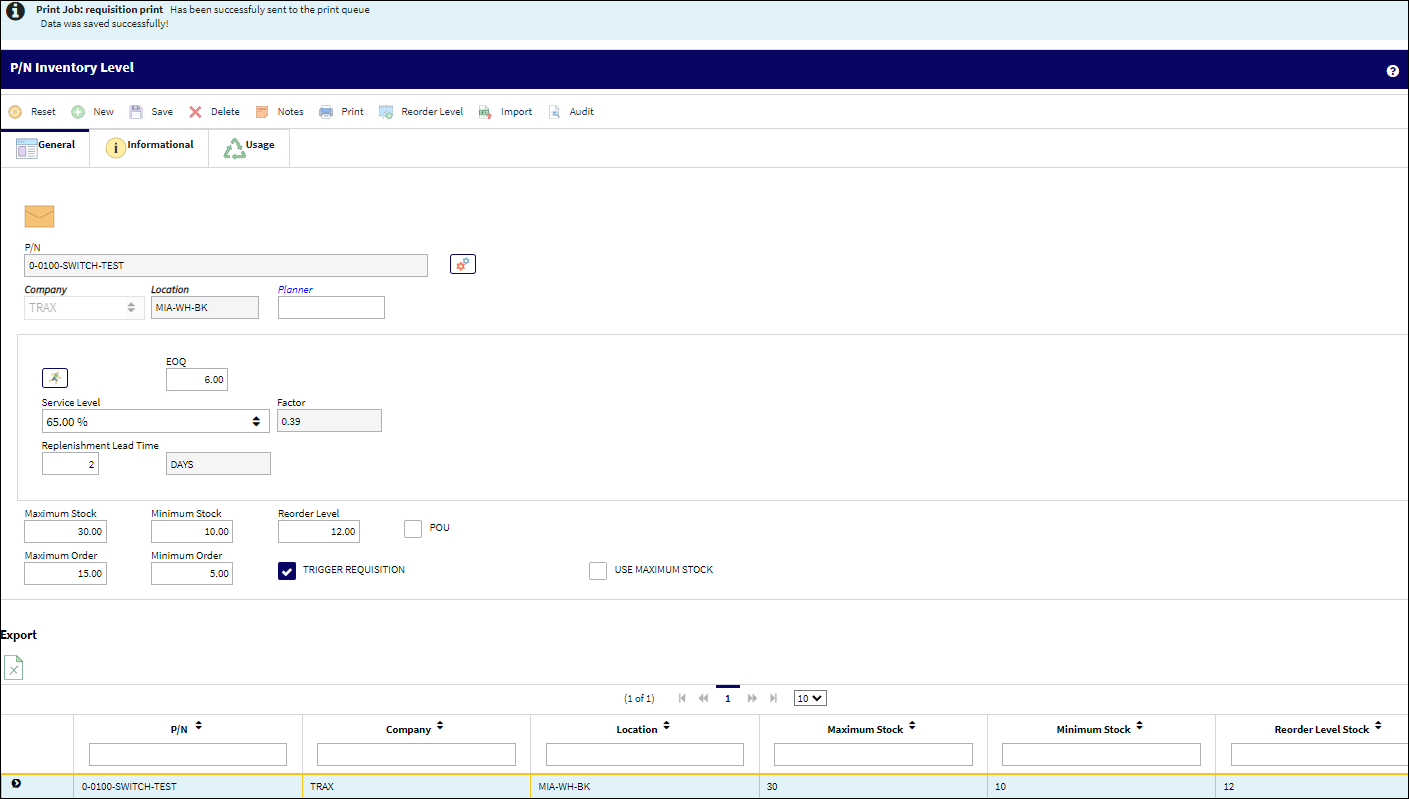

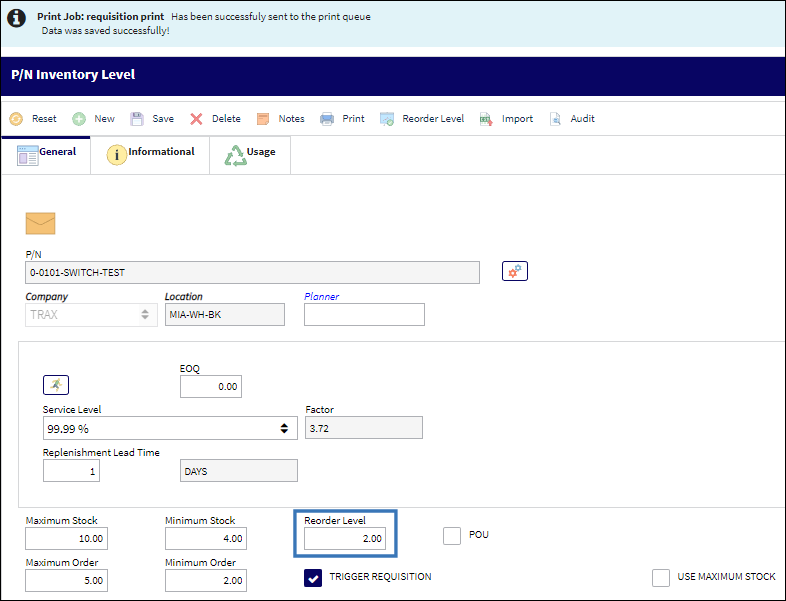

In the P/N Master, set up the Poisson, Service Level, Replenishment Lead time, and the Maximum and Minimum Stock values. Ensure that the Reorder Level is populated and the Trigger Requisition check box is checked. When the Trigger Requisition checkbox is checked, a requisition automatically generates when a Material Issue transaction causes the available stock to drop below the manually set or system calculated reorder levels.

The Maximum, Minimum and Reorder values are now displayed for the part at the P/N Inventory Level.

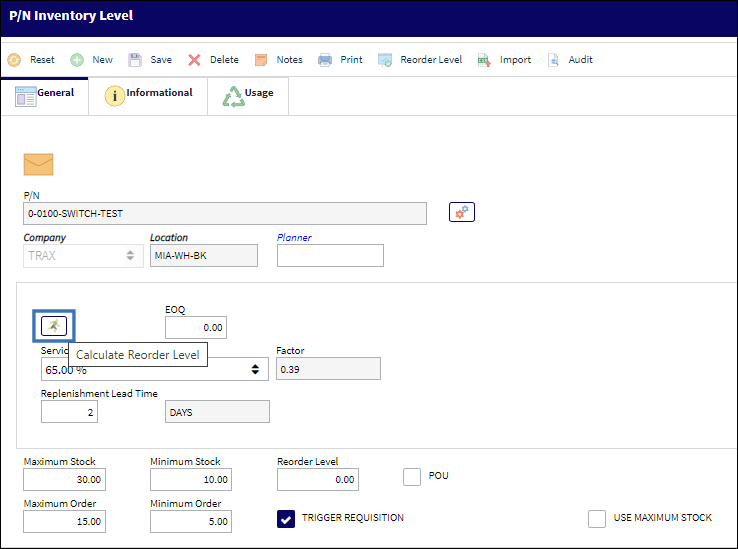

Once a sufficient transaction history is established for a part, the Calculate Reorder Level ![]() button prompts the system to recalculate reorder levels based on the actual reorder history.

button prompts the system to recalculate reorder levels based on the actual reorder history.

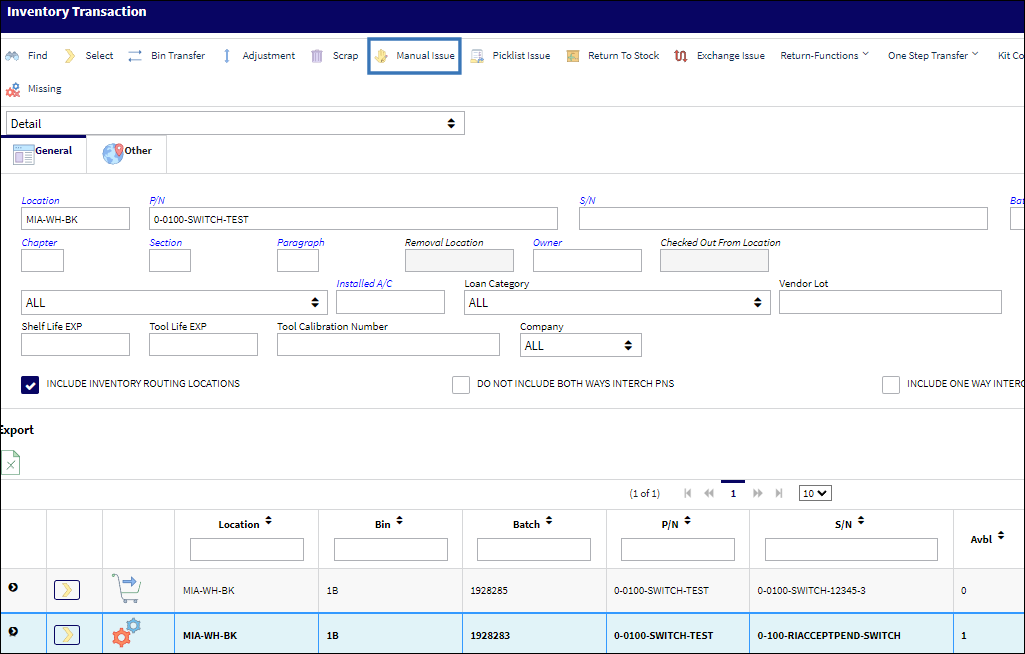

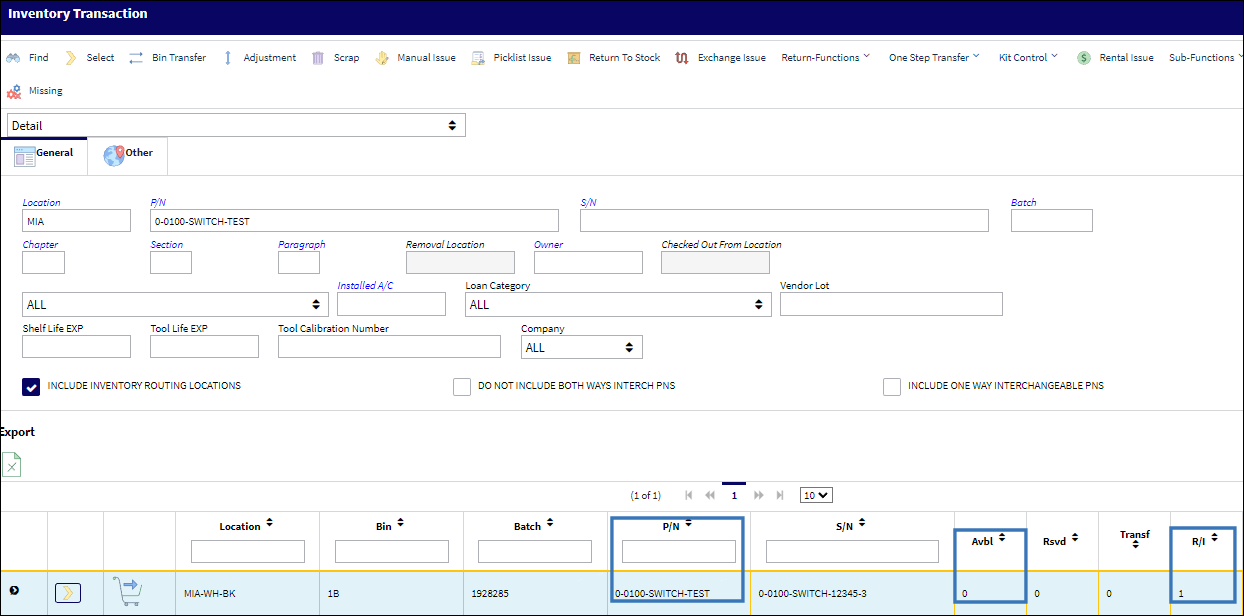

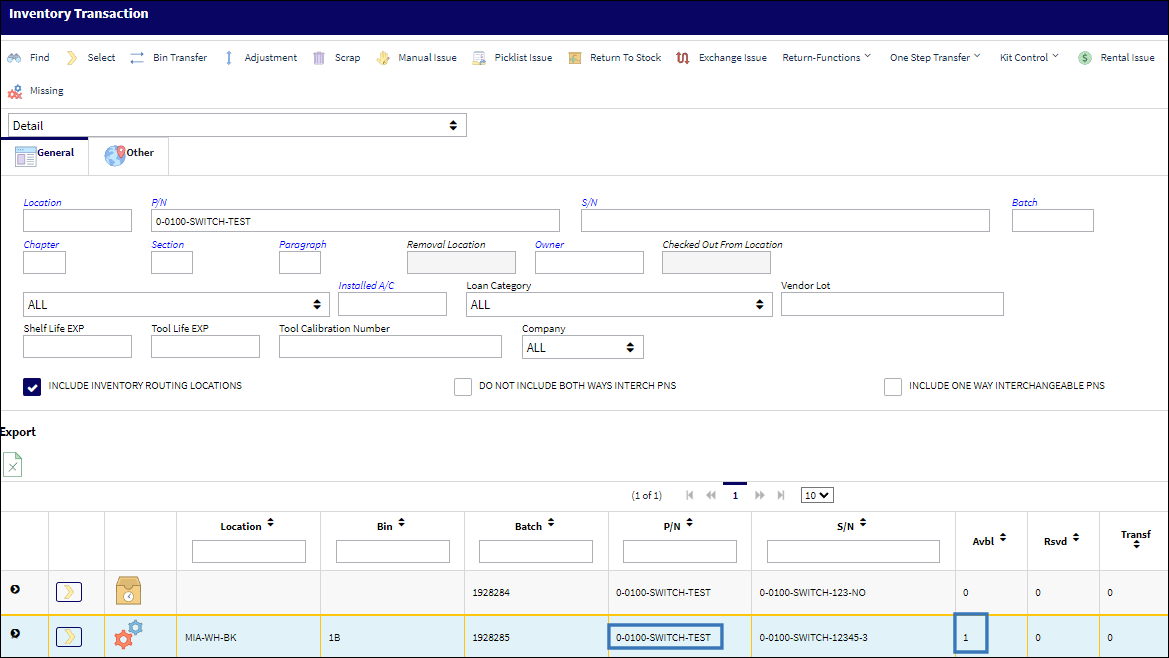

From the Inventory Transaction screen, select a part for issue. Notice that the selected part has one unit in available stock. Also note that this quantity is below the Minimum Stock level of ten (10) each set up in the P/N Master.

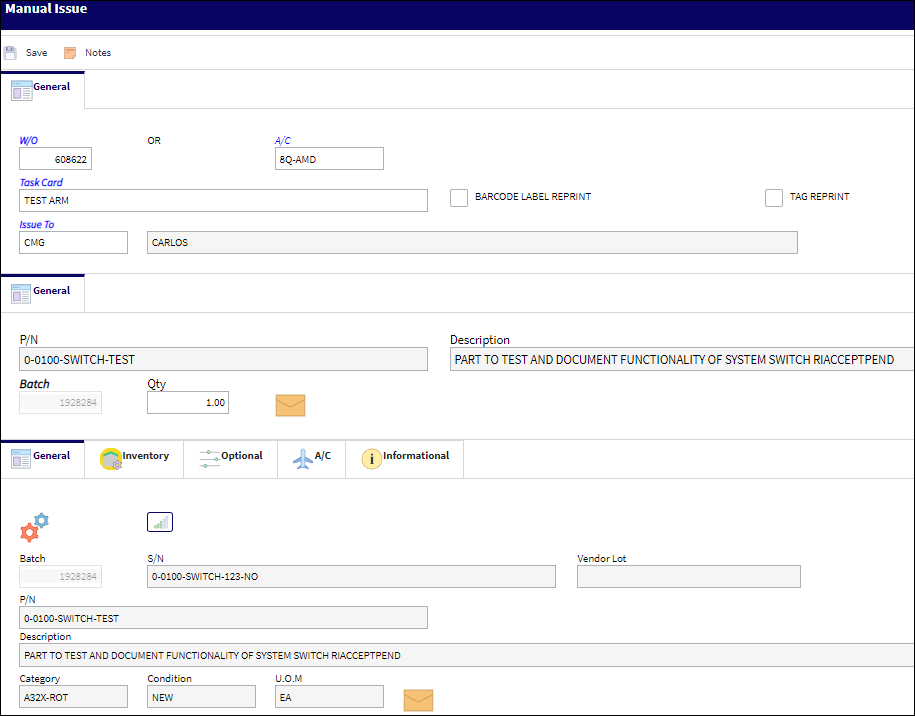

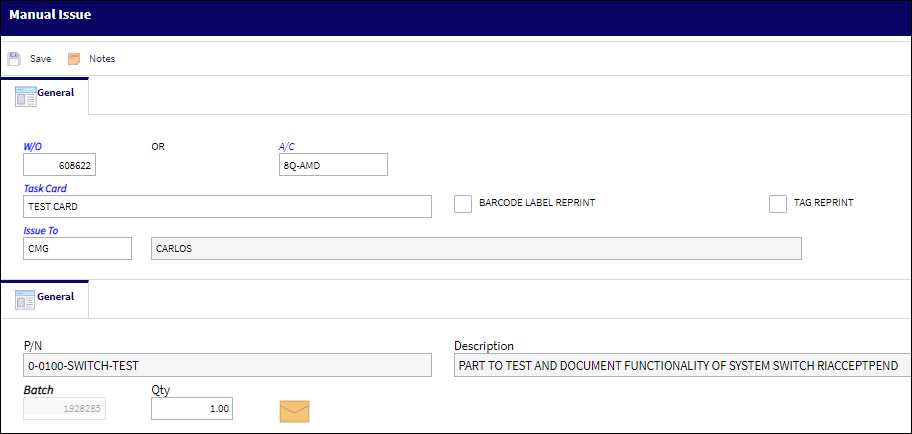

This available part was Manually Issued to a Work Order and the transaction saved.

Notice that the updated status for this part displays zero units in Available (Avbl) inventory and one unit in Receiving Inspection (R/I).

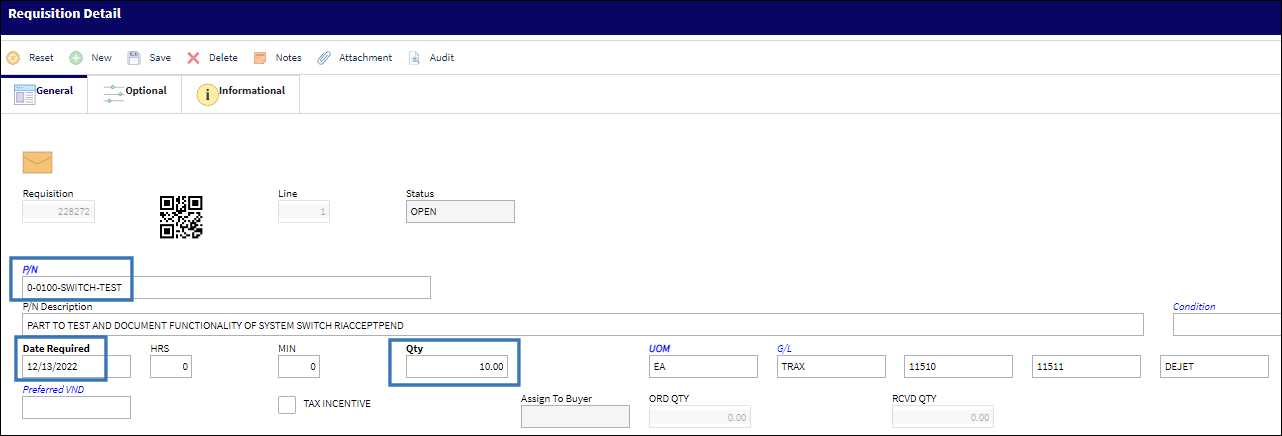

The low stock condition prompted the system to generate a requisition to purchase additional units when the last unit was issued. Notice that Requisition number 228272 for the part number was generated to purchase 10.0 each units. This number matches the Minimum Stock value that was manually set up for the new part. The reorder value for a part can be dynamically updated by the system once sufficient reorder data is available.

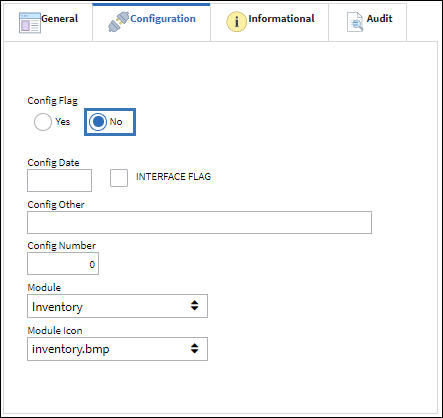

Switch set to No:

When set to No, the system will allow you to manually set the re-order level.

The system will also automatically trigger a requisition for a new part if a Reorder Level quantity is entered in the Inventory Level of the P/N Master and the Trigger Requisition checkbox selected. A Reorder Level quantity of 2.00 each was entered, and the Trigger Requisition checkbox is selected for a new part in the example below.

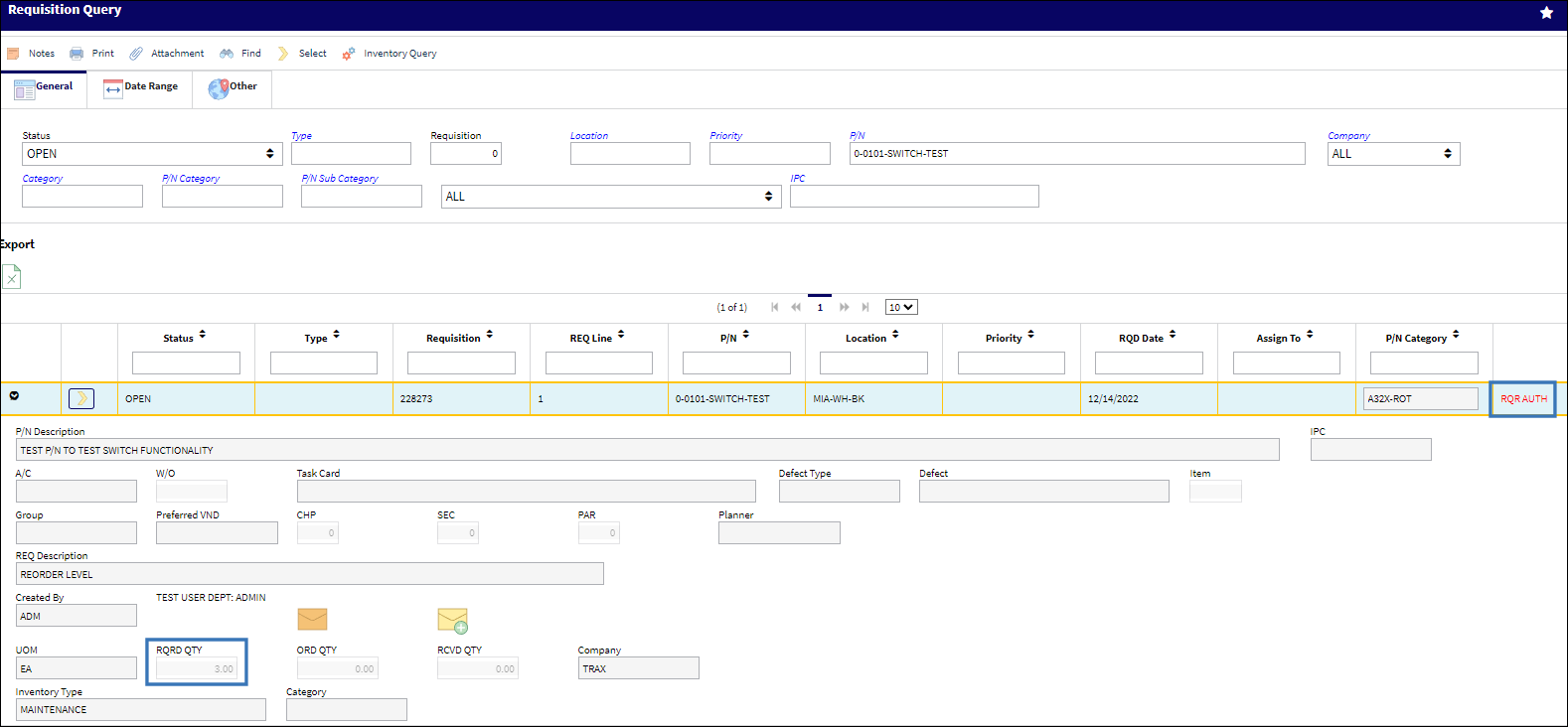

A Requisition Query was executed for the new part number after saving the P/N Master and Inventory Level detail. Notice that the system automatically generated Requisition Number 228273 for 3.00 each as evidenced in the Requisition Header below. The requisition will require authorization through the Requisition Authorization Explorer.

Note: System Administration Switch REQATHREL must be set to Yes in the Requisition Authorization Explorer in order to enable a Requisition Authorization.

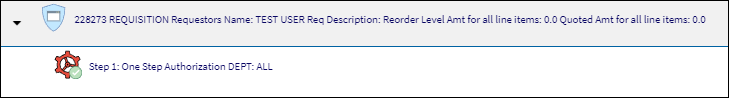

Expand the requisition record in Requisition Authorization Explorer to access the One Step Authorization.

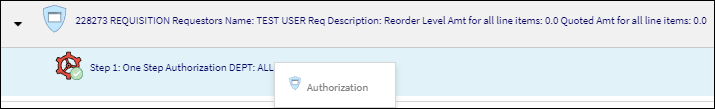

Click on the Authorization pop-up button to authorize the requisition.

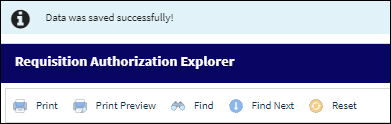

The Requisition Authorization Explorer saves the authorization.

For the last example, the switch is again set to No and a reorder level was Not established for the part to test full functionality of Switch REOEAUTO. A P/N with available stock for issue was selected. Notice that there is only one unit available in inventory.

A Manual Issue of the only unit for this part was executed.

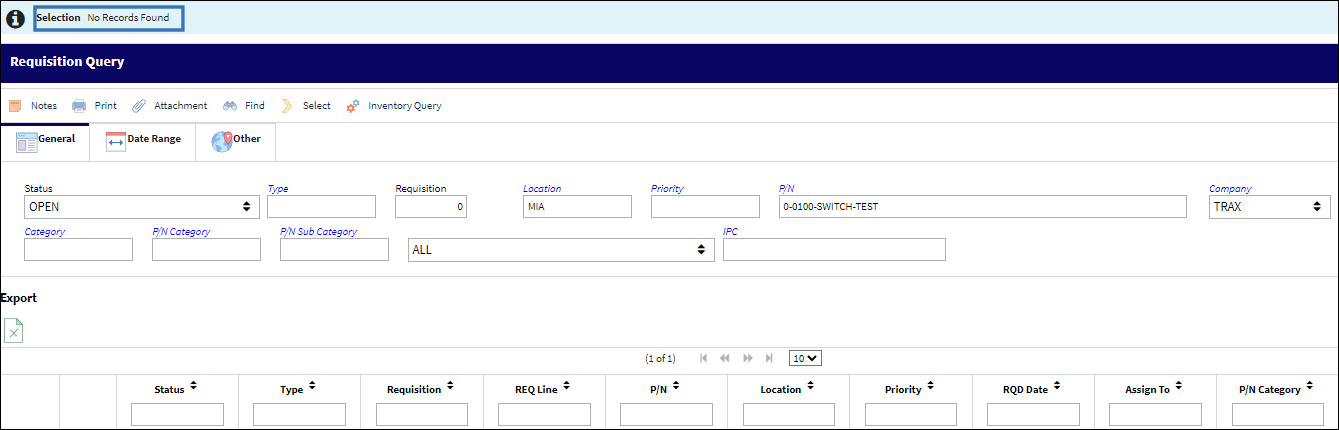

In this configuration, a requisition was not automatically created by the system even though there was low stock availability for the part as evidenced by the negative return for the Requisition Query below.

Share

Share

Print

Print