Share

Share

Print

Print

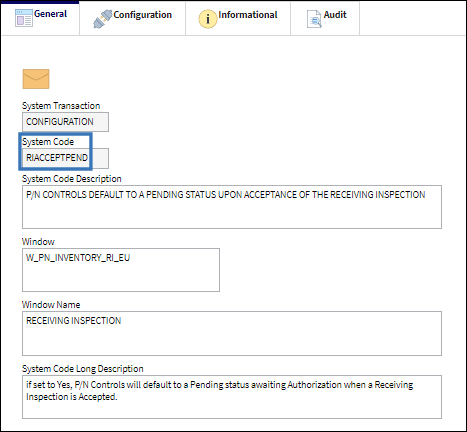

RIACCEPTPEND - P/N Controls default to 'Pending' on Acceptance of Receiving Inspection

P/N Controls default to 'Pending' on Acceptance of Receiving Inspection

Affected Window: w_pn_inventory_ri_eu

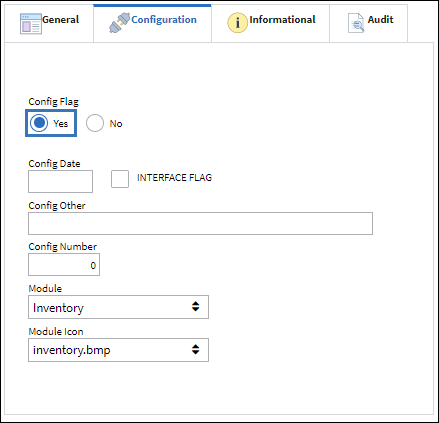

Switch Set to Yes:

When set to Yes, P/N Controls will default to 'Pending' Authorization when accepted through Receiving Inspection.

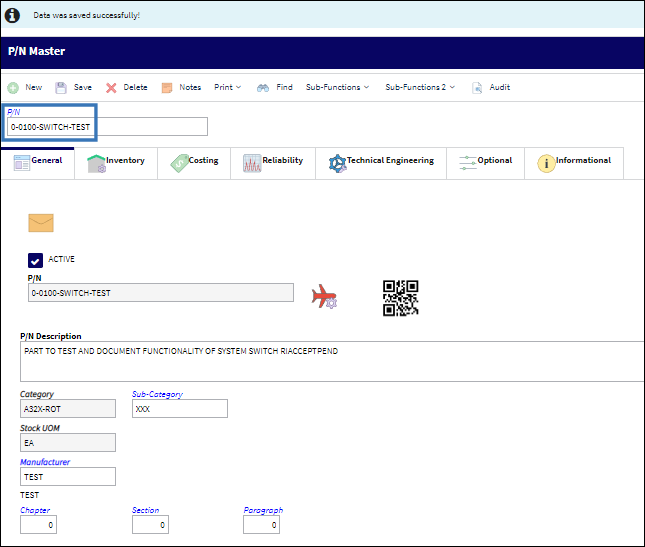

The following P/N Control was created for a rotable part.

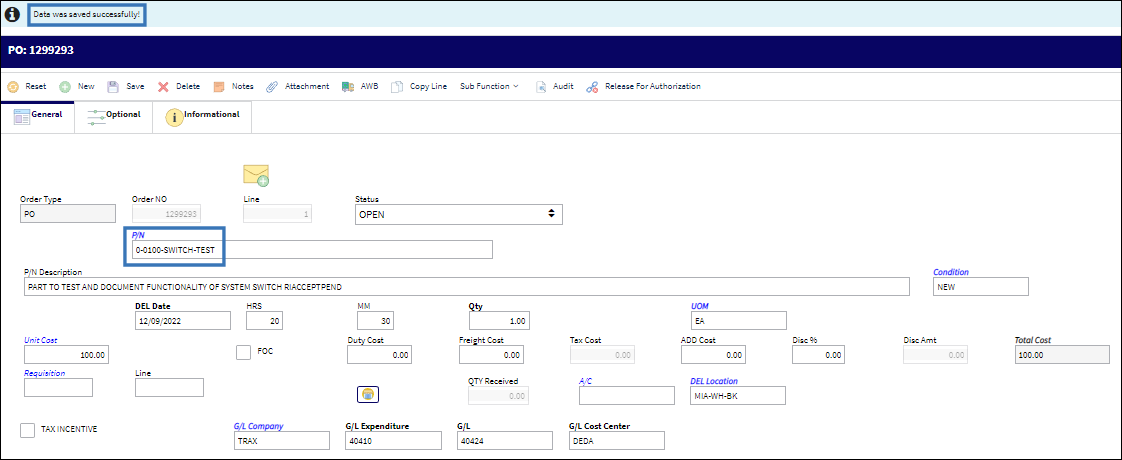

A Purchase Order is then created to order the part added to the part number master.

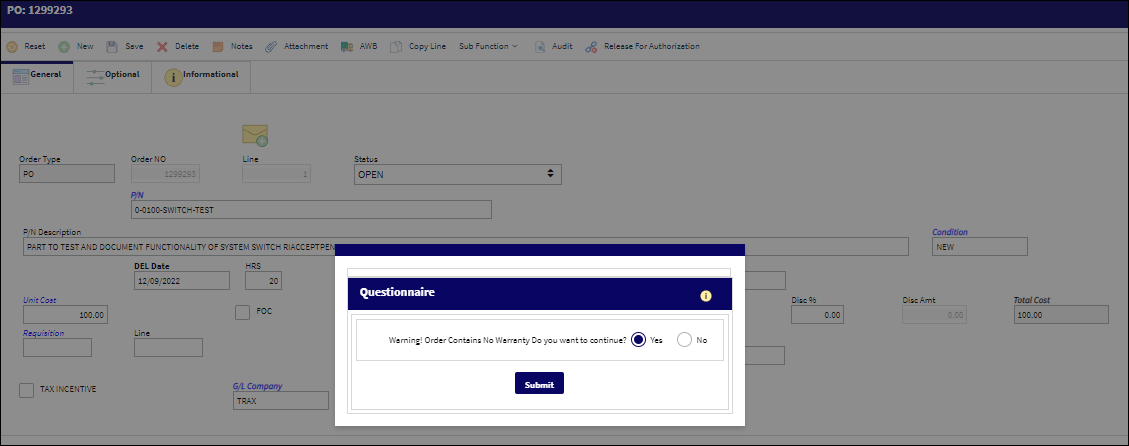

The Purchase Order is then used to order the part. A pop-up dialog presents a soft warning for the warranty status, if applicable.

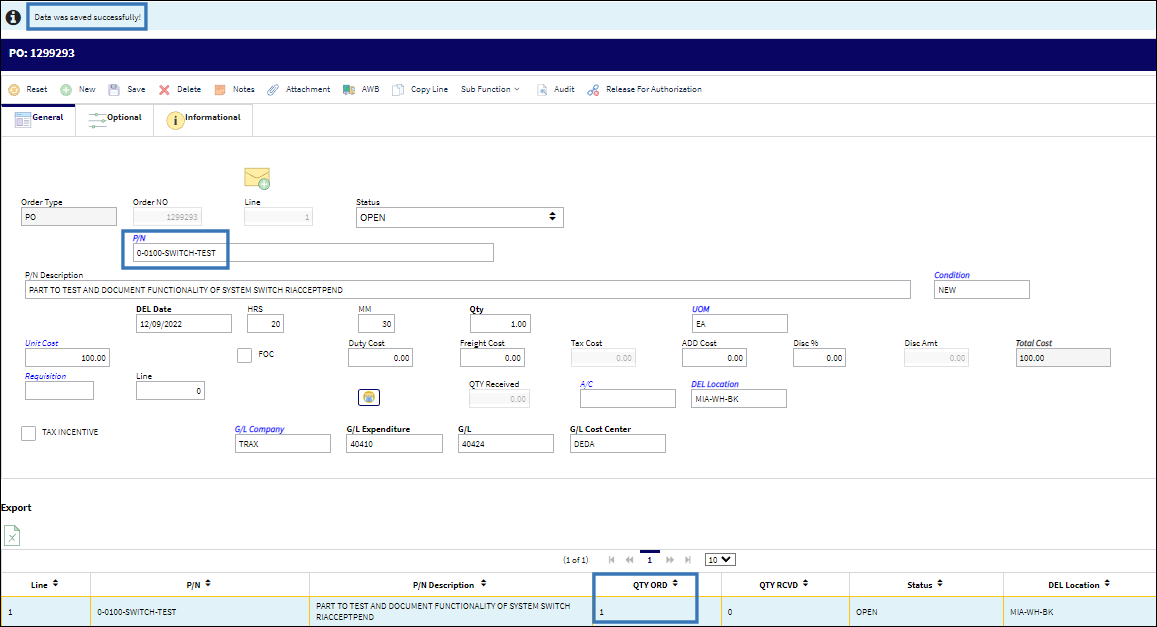

The order is created once the the radio button Yes is selected and the transaction submitted. Notice that the Quantity Ordered column (QTY ORD) now reflects 1 each.

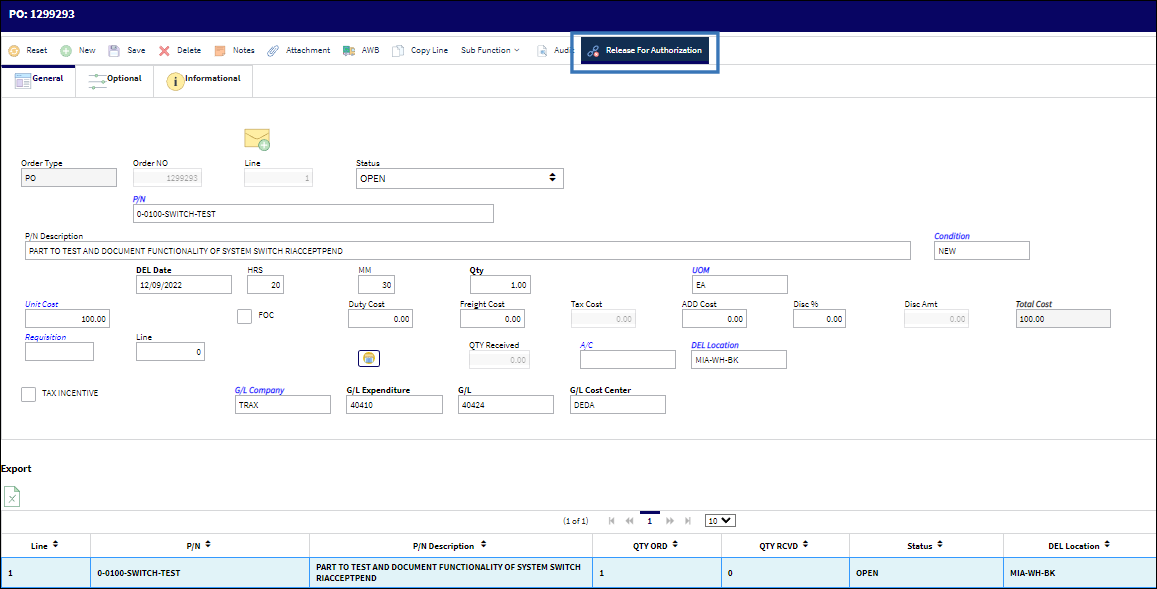

The order must be released for authorization using the ![]() Release for Authorization button.

Release for Authorization button.

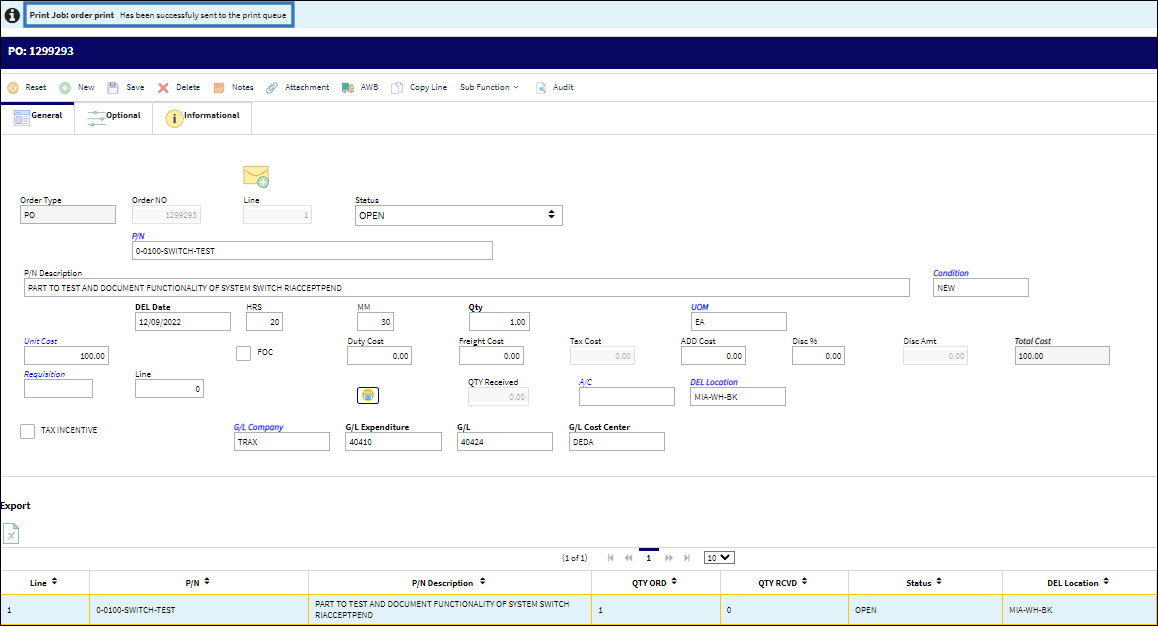

The the Release for Authorization for the order is then sent to the print queue.

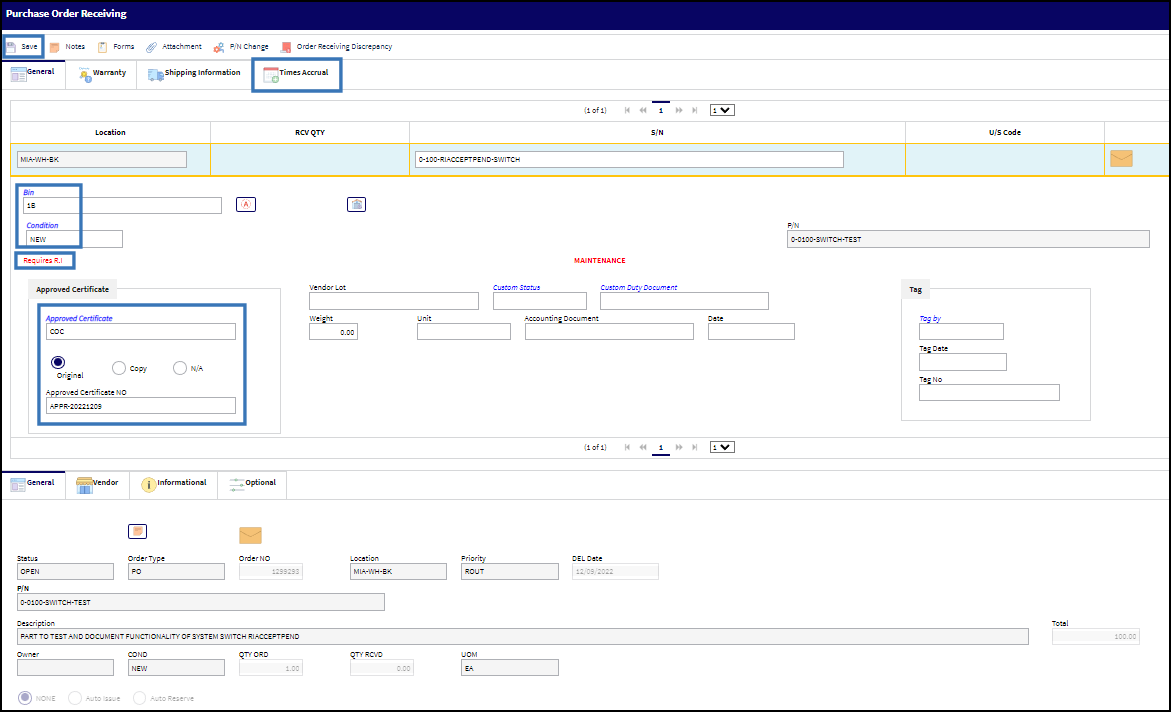

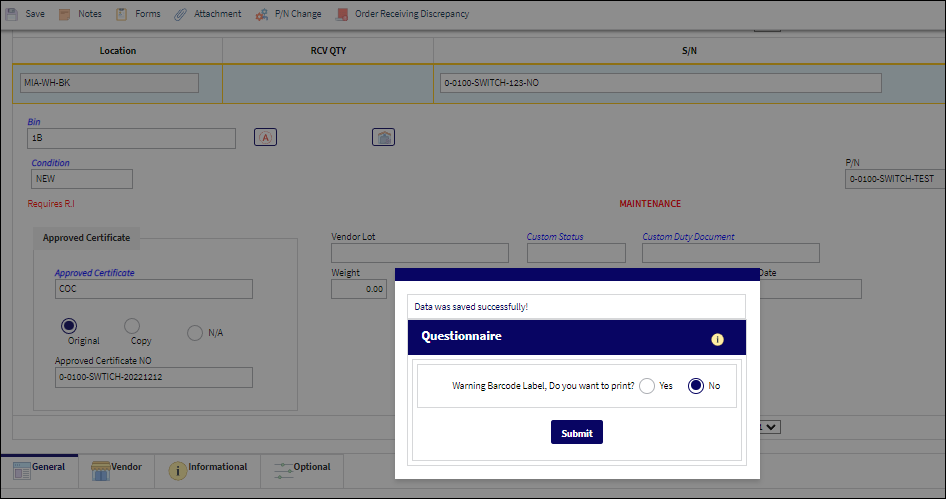

The order is then received. Complete the requisite order detail and save the receipt transaction.

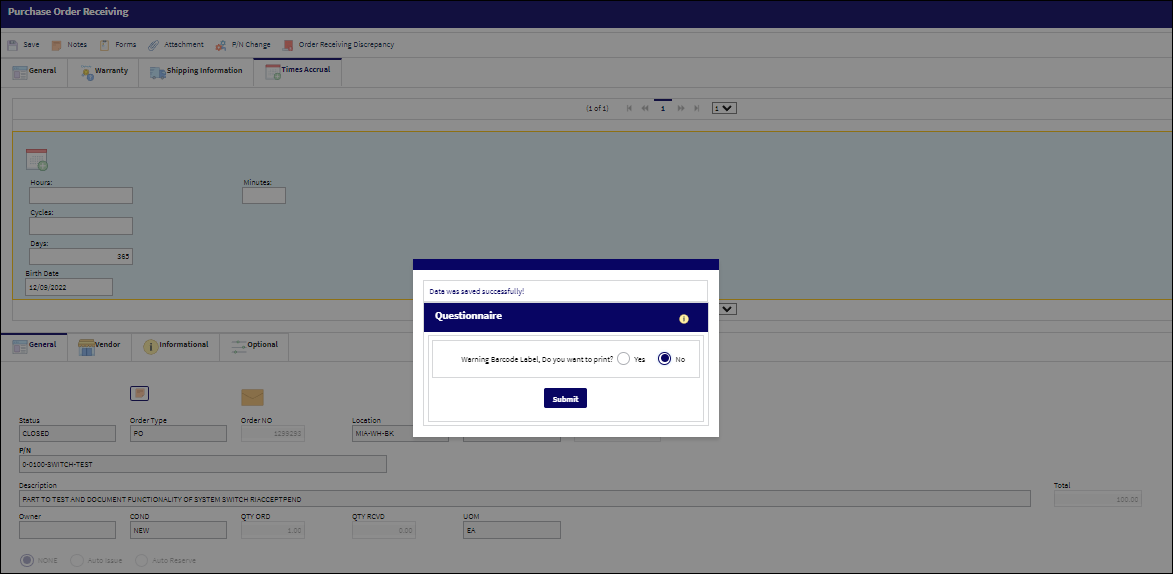

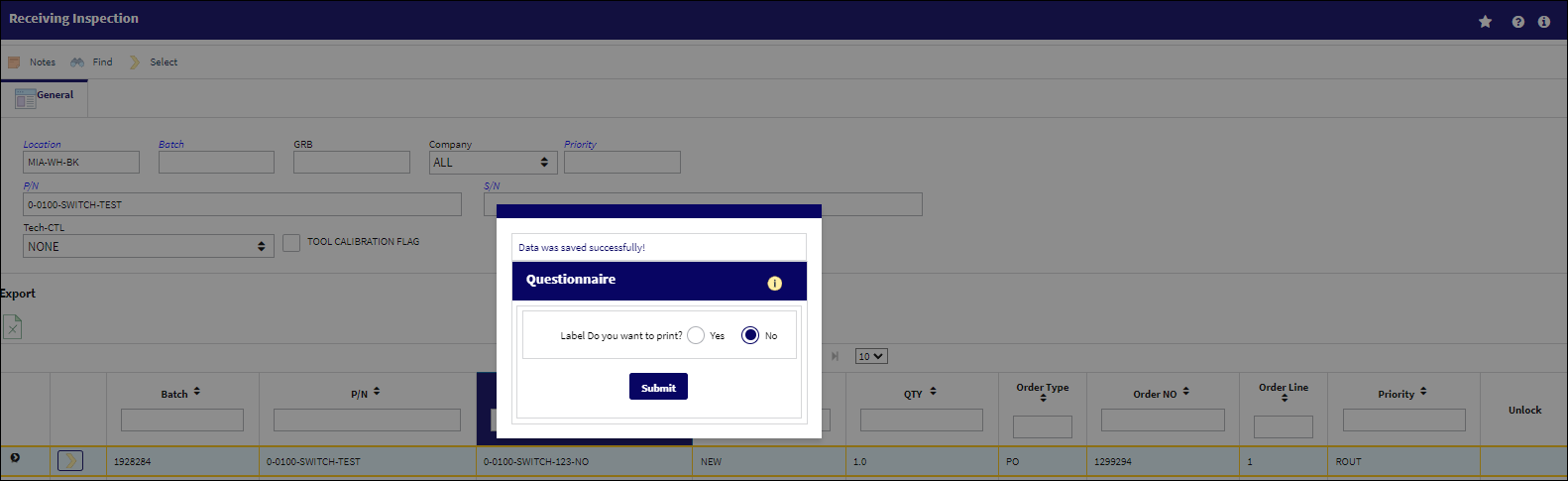

A pop-up dialog presents with a soft warning to print a barcode label for the item. Respond and submit the receipt transaction.

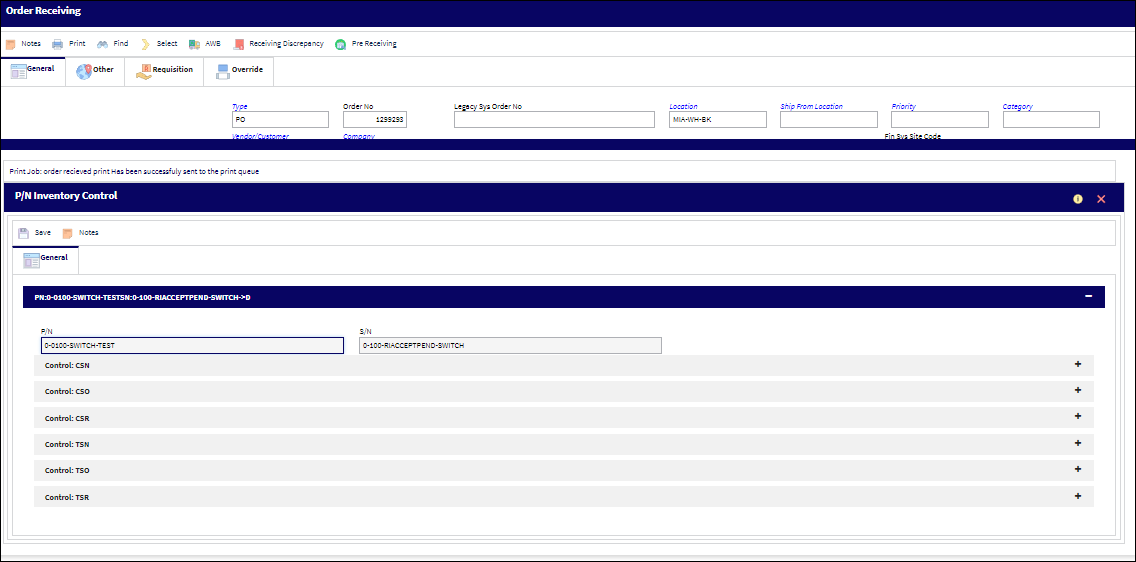

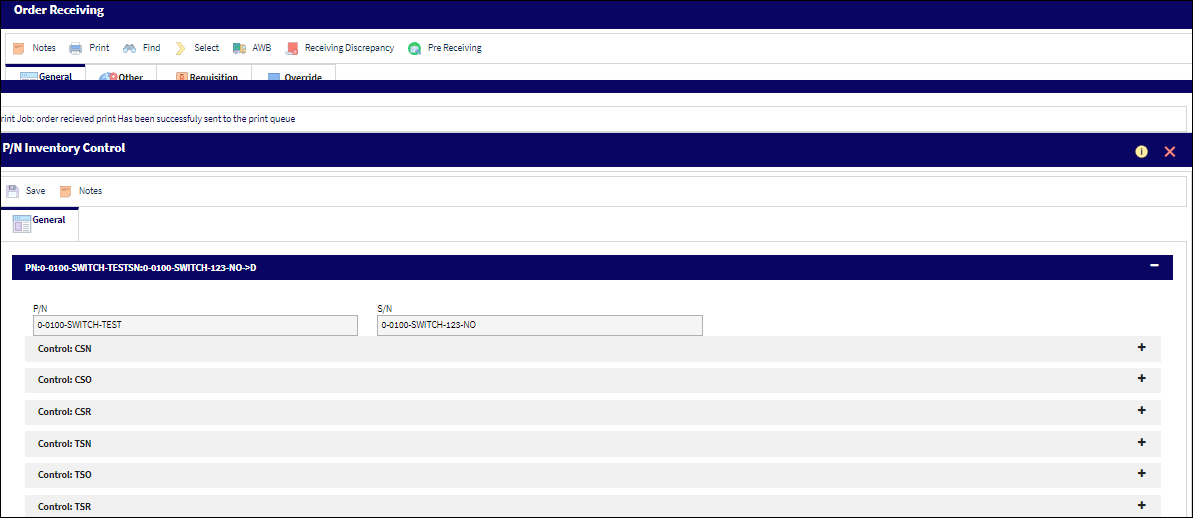

The P/N Inventory Control Print Queue then presents. Select to add any part number controls required (CSN, CSO, CSR, etc.), and save the print order.

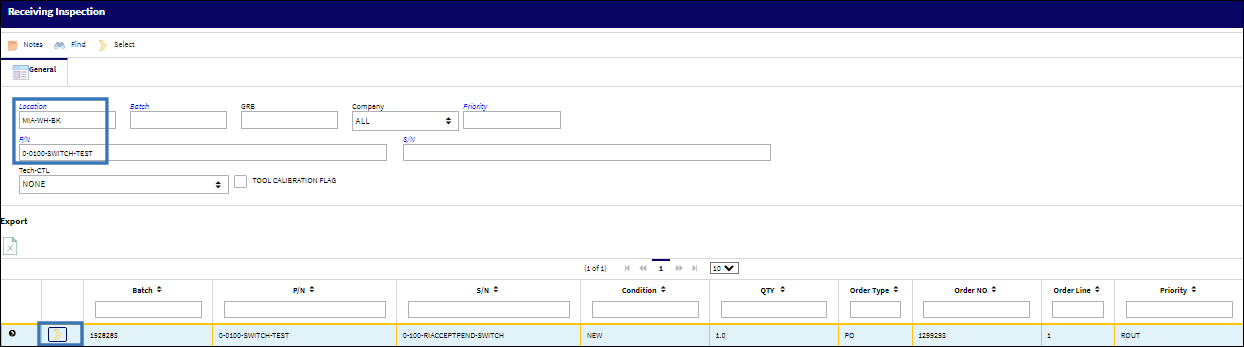

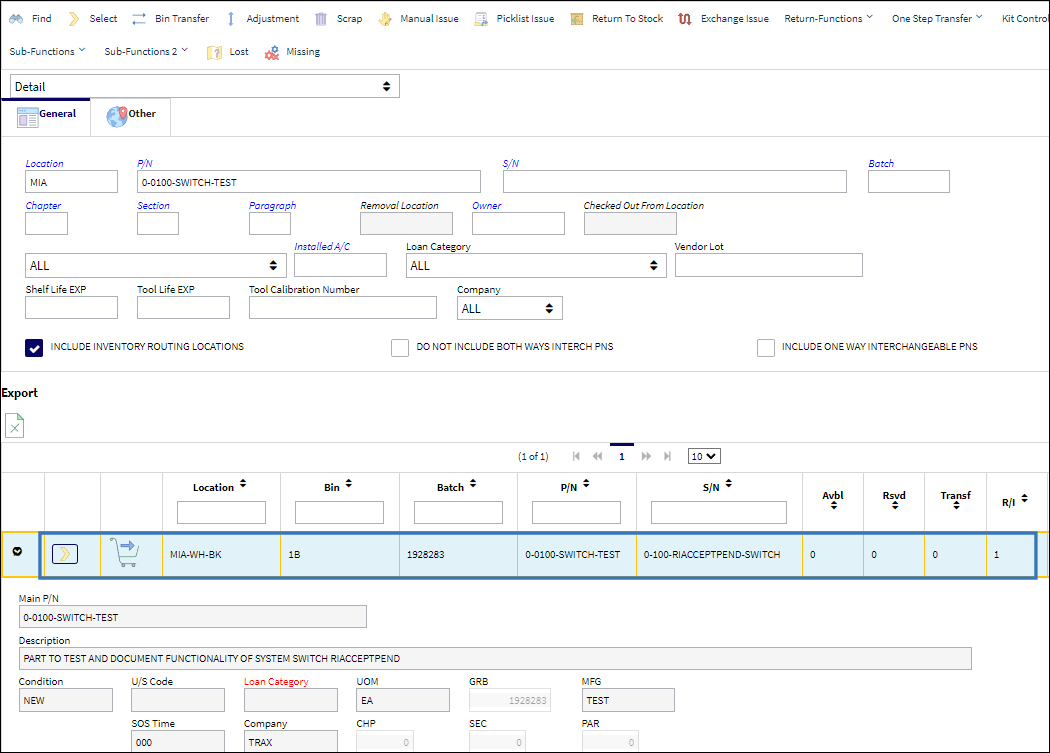

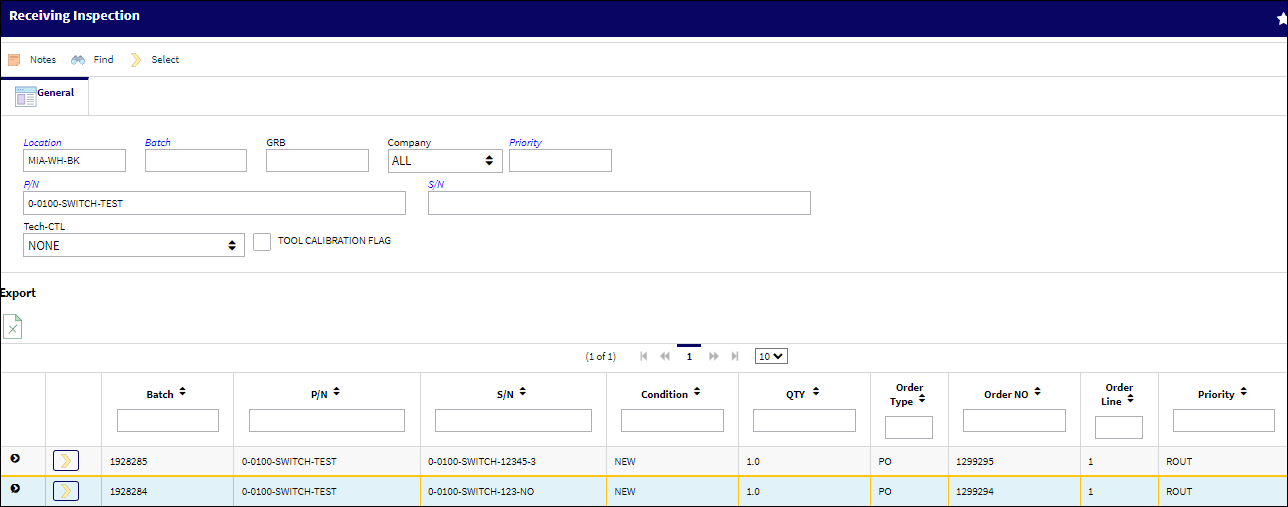

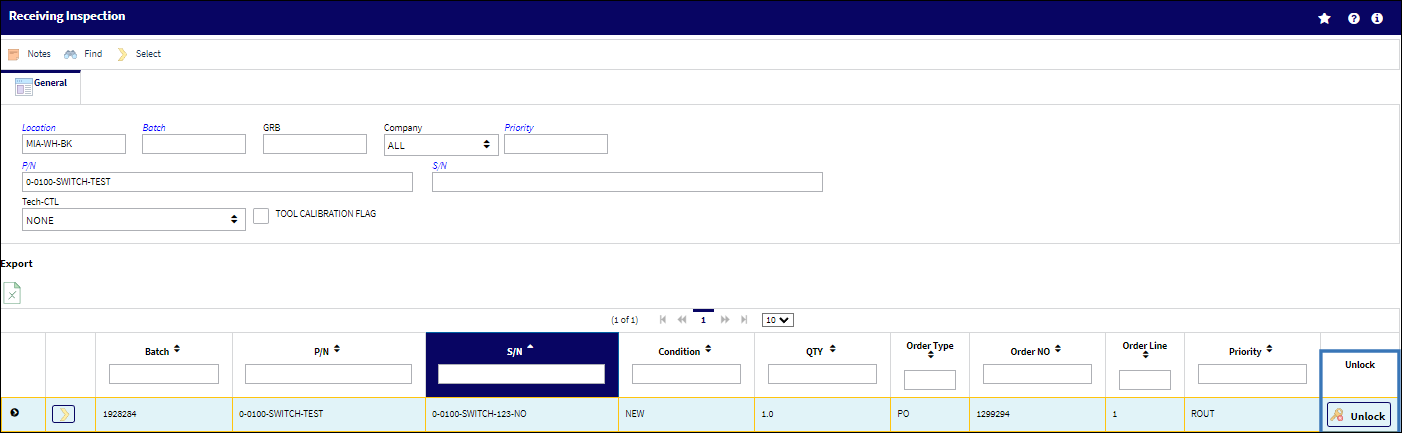

The item will now be available to perform the Receiving Inspection. Select the item from the Receiving Inspection transaction screen.

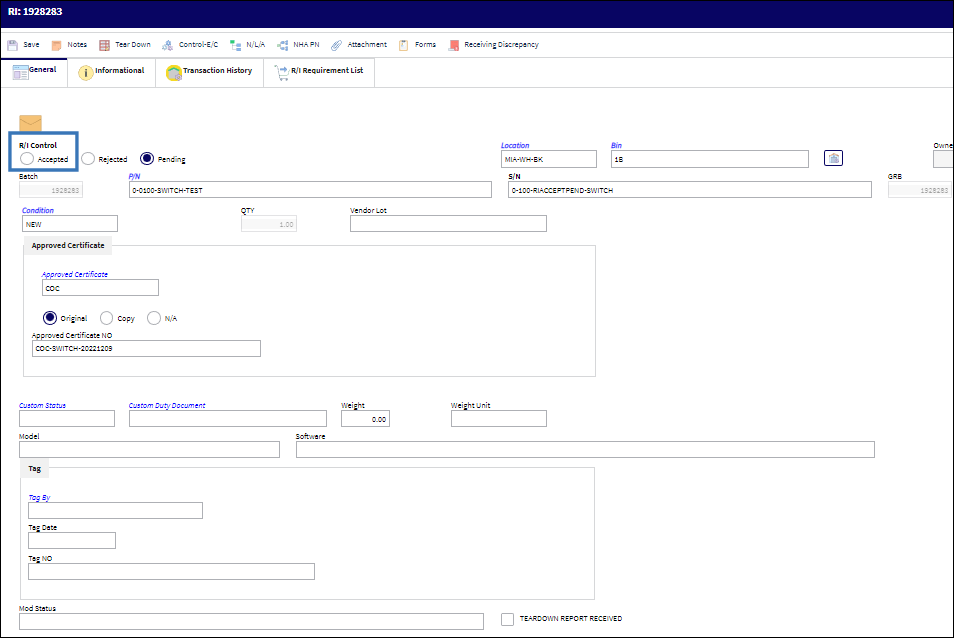

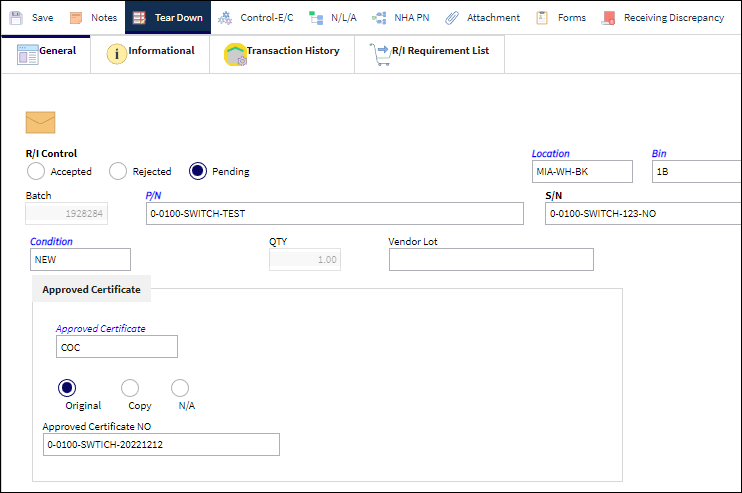

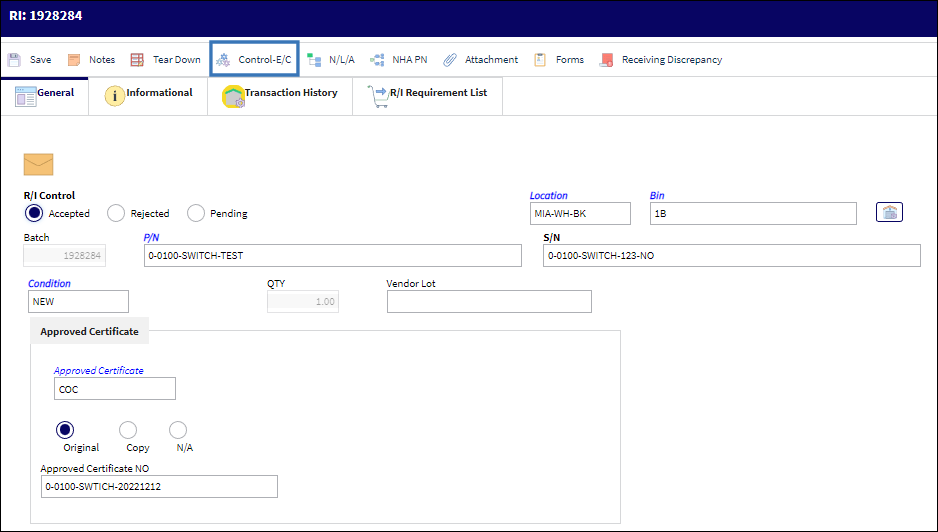

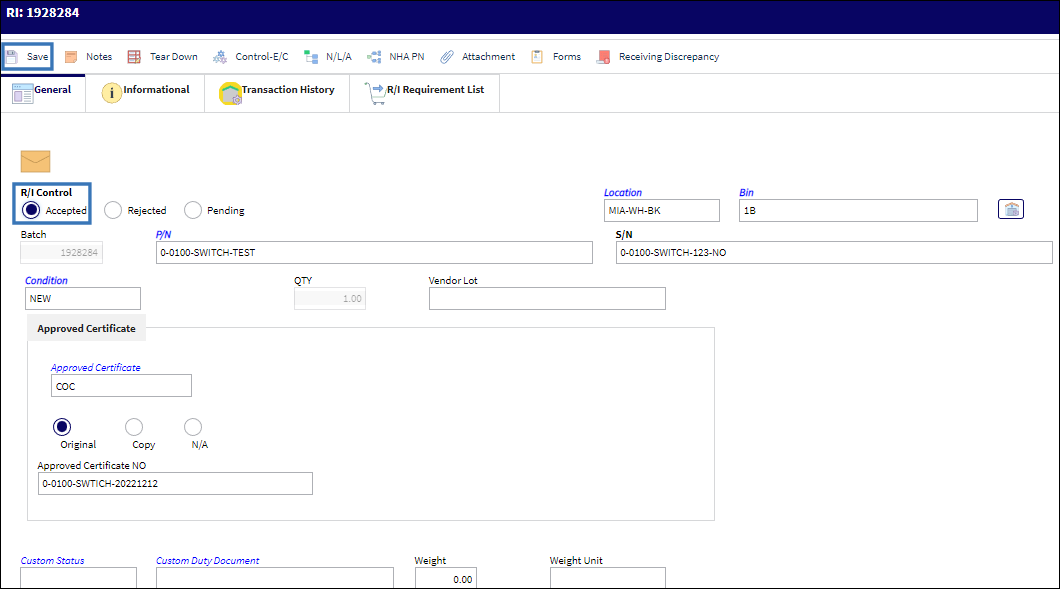

Document the requisite information for the type of part; a rotable with engineering controls was used for this example, and accept or reject the item as appropriate.

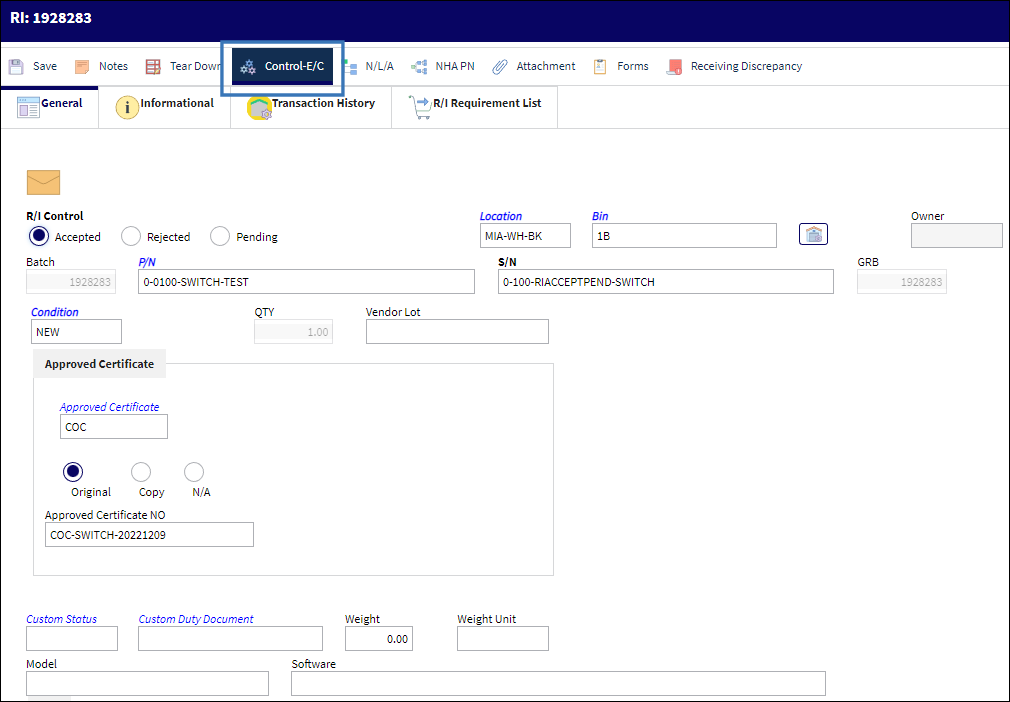

If an engineering control for the part exists, document any P/N engineering controls via the ![]() Control E/C button before saving the transaction.

Control E/C button before saving the transaction.

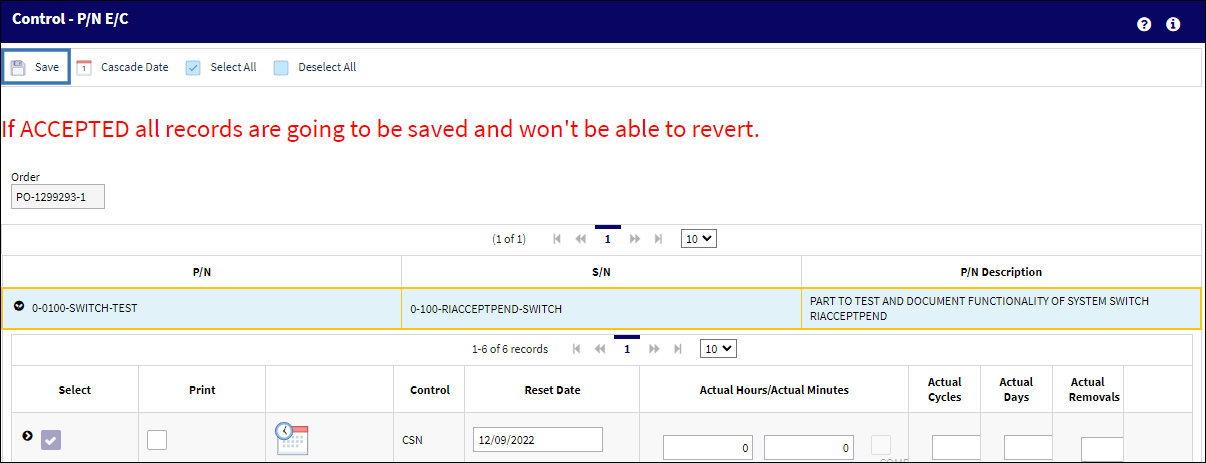

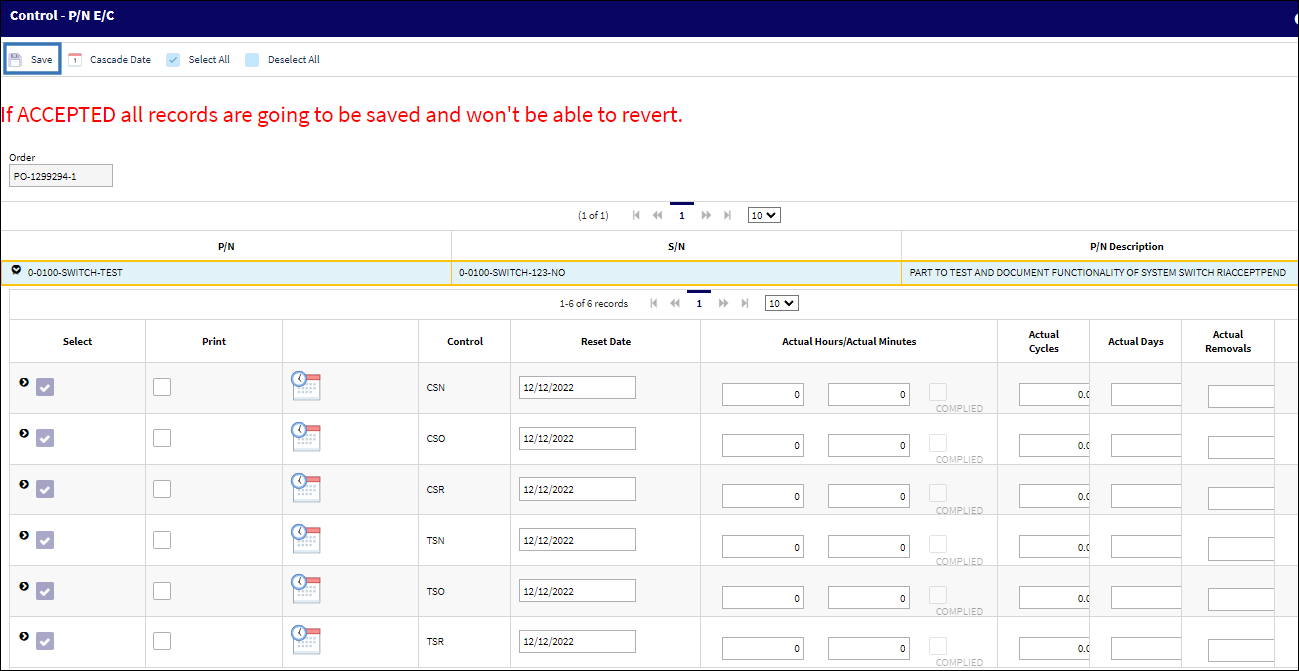

The Engineering Control screen for the Part Number populates. Complete the record and save as appropriate.

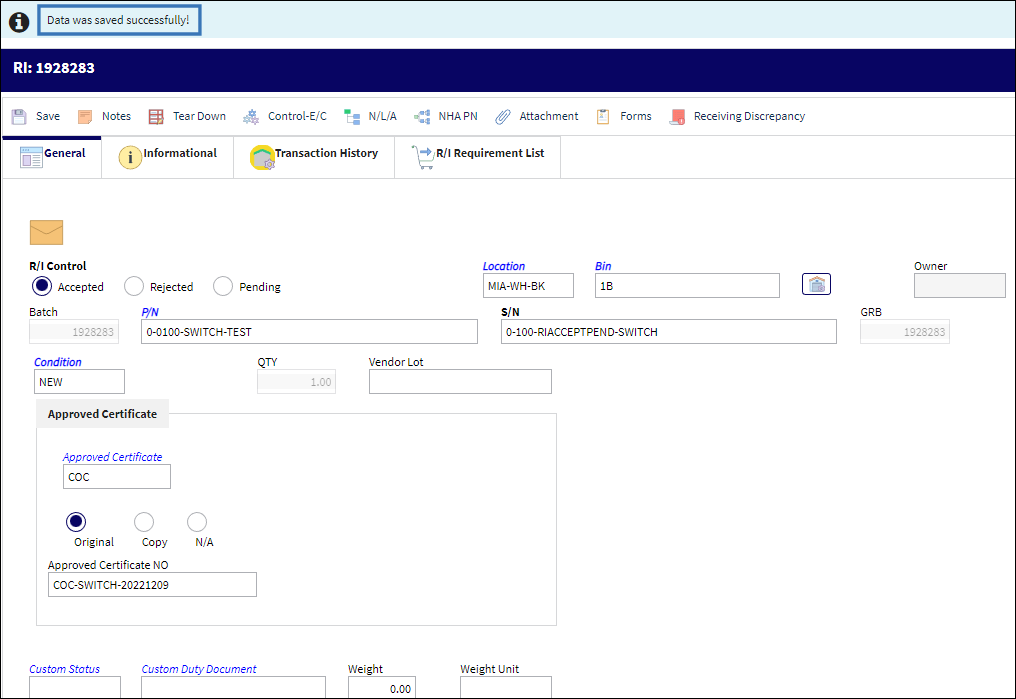

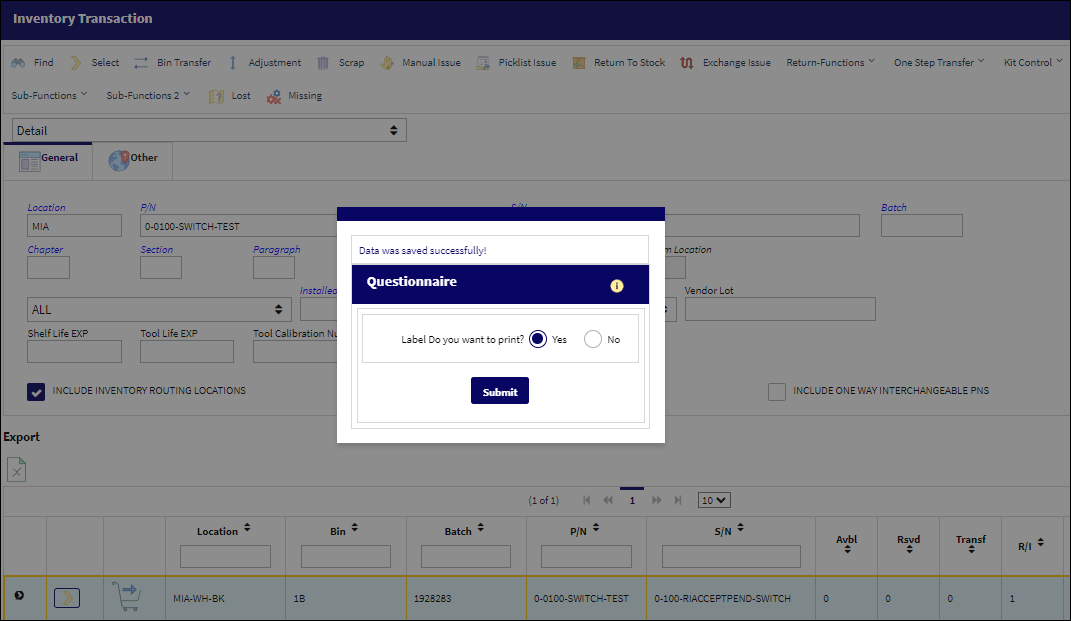

The Receiving Inspection has now been successfully saved.

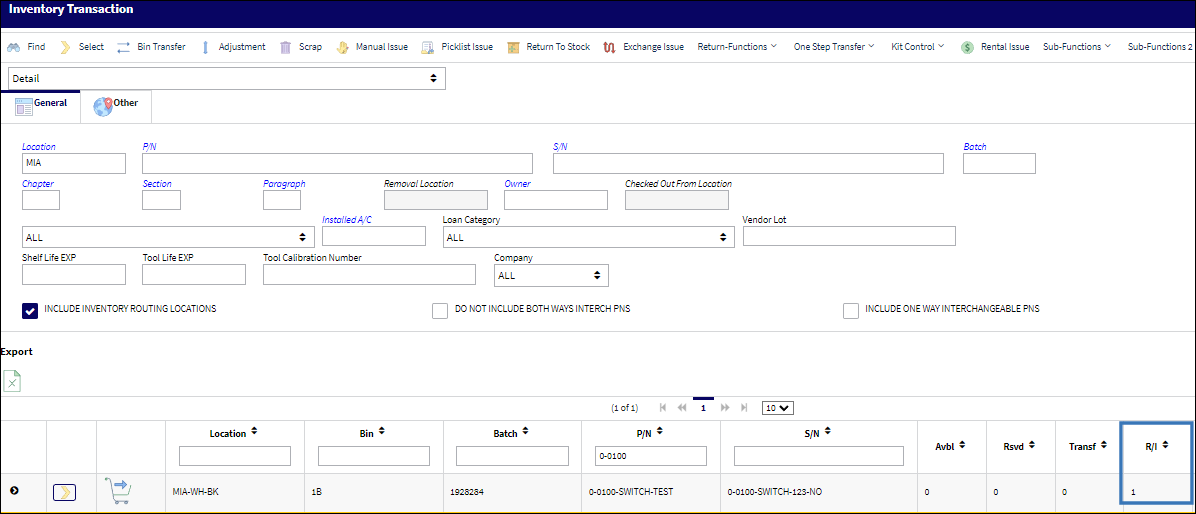

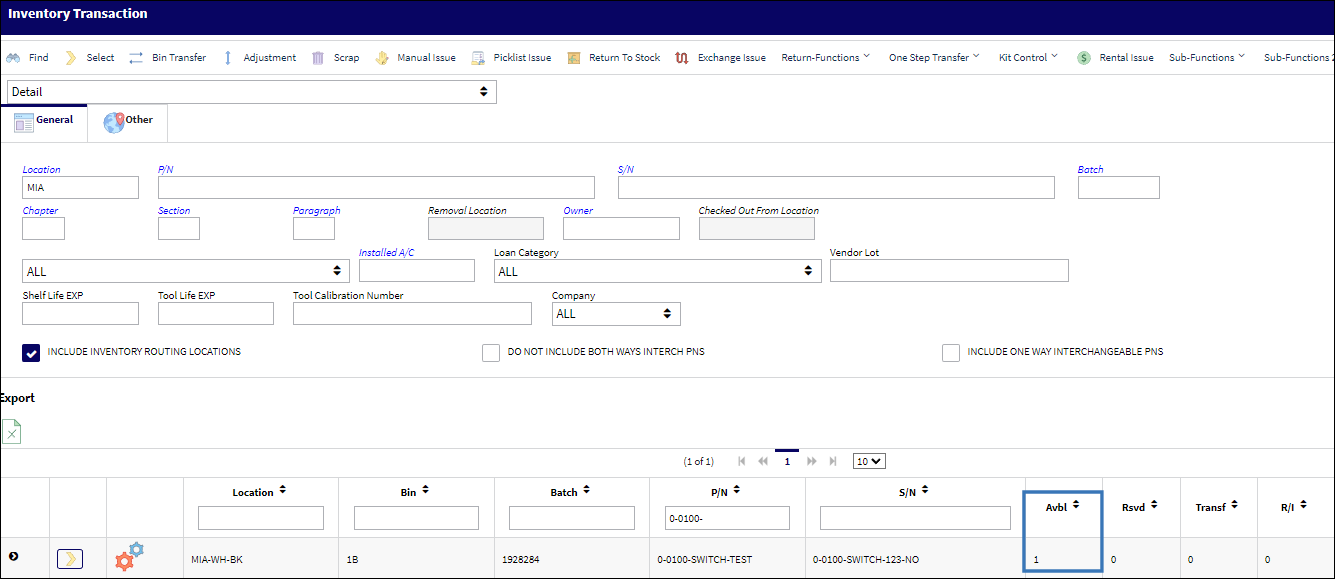

Notice from the Inventory Transaction screen that the part is still listed in a Receiving Inspection status. The part remains in R/I status until the updated status label is printed, and the required Bench Check or Test/Tear down report is documented for the part to be authorized.

An updated status label presents in the pop-up print dialog. Respond and submit to print the label.

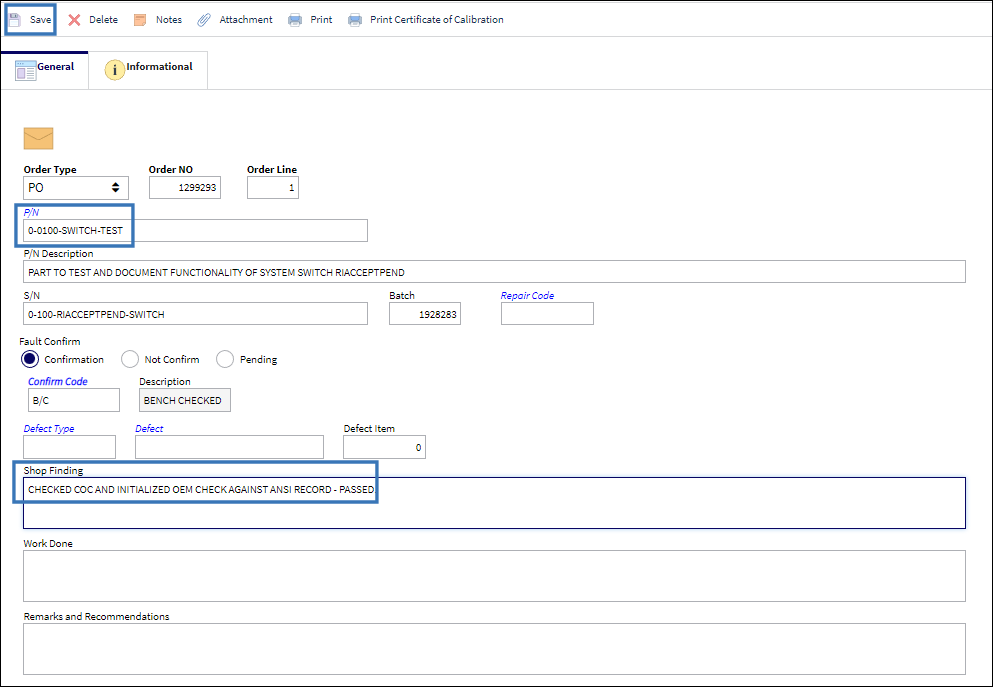

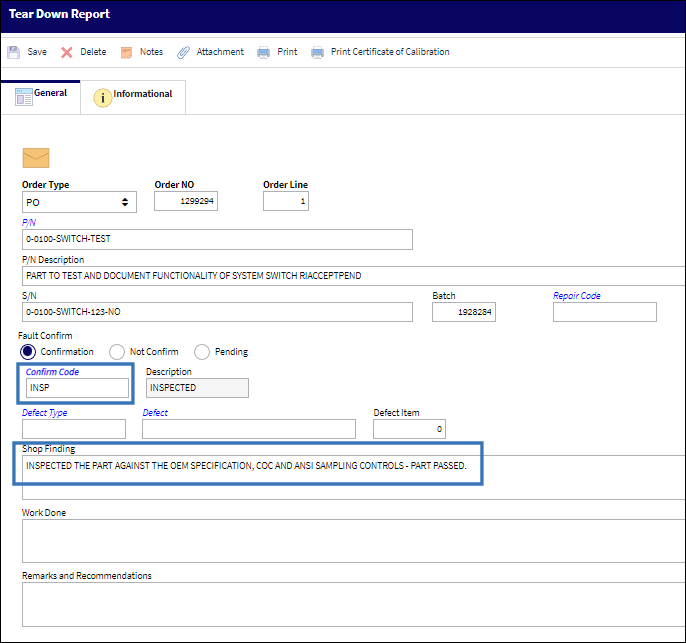

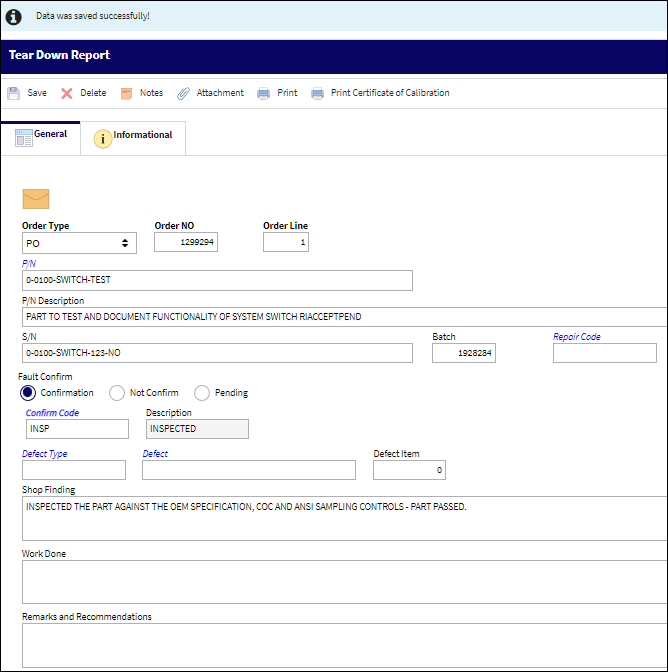

The Bench Check / Tear Down Report can now be documented as shown below. Document the results and save the transaction.

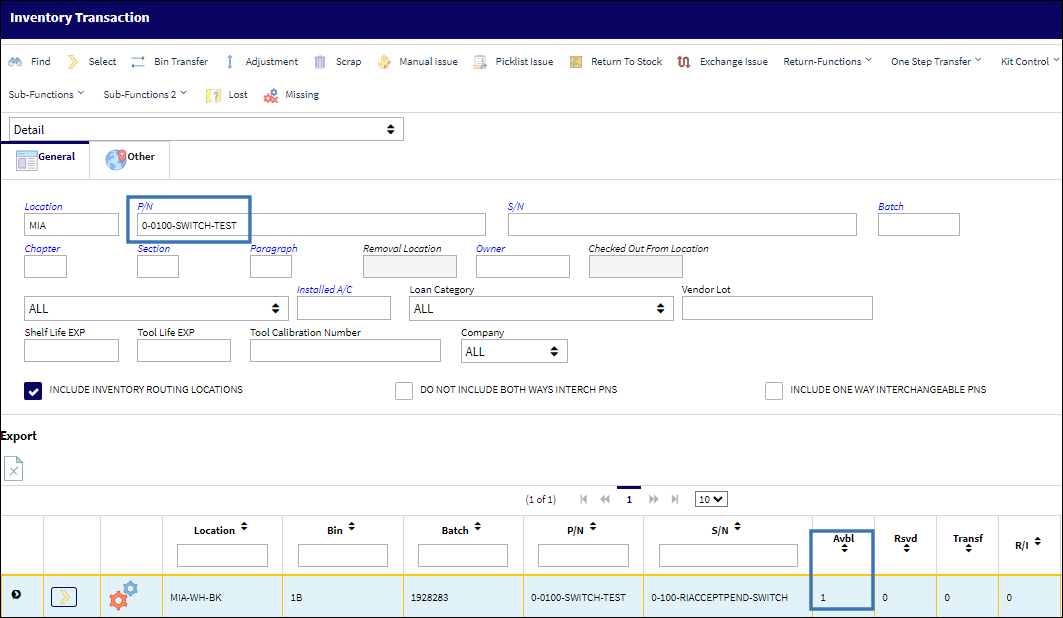

The status for the part changes to available in inventory once it is authorized after completion of the requisite Receiving Inspection(s), satisfying Engineering Control(s), and saving the acceptable Bench Check or Tear Down report. The change to the part's availability status is evidenced in the Inventory Transaction screen below.

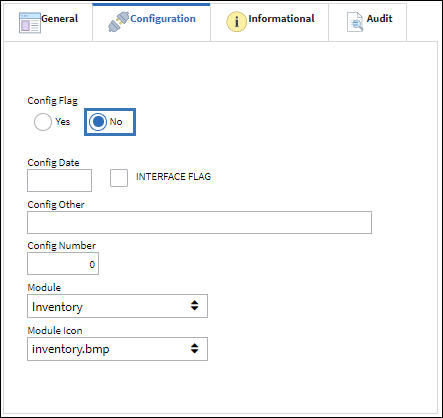

Switch Set to No:

When set to No, P/N Controls will remain in 'Authorized' status by default when accepted through Receiving Inspection.

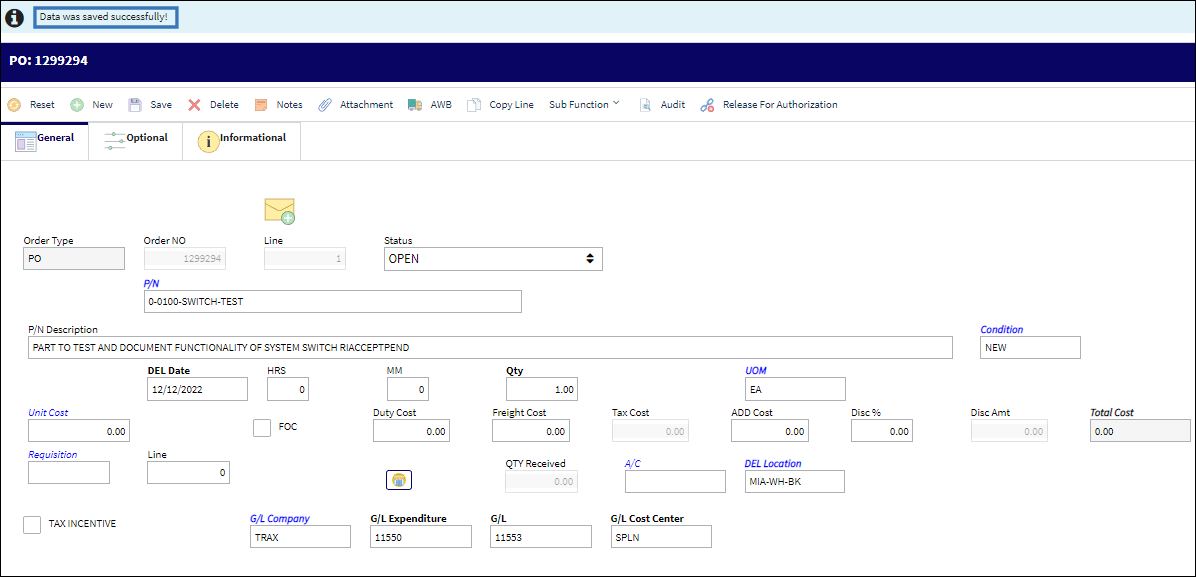

A new Purchase Order was created for the same part number. However, with the switch configuration set to No, the order is sent directly to Order Receiving. Since the order is authorized when the switch is set to No, the![]() Release for Authorization button is not required.

Release for Authorization button is not required.

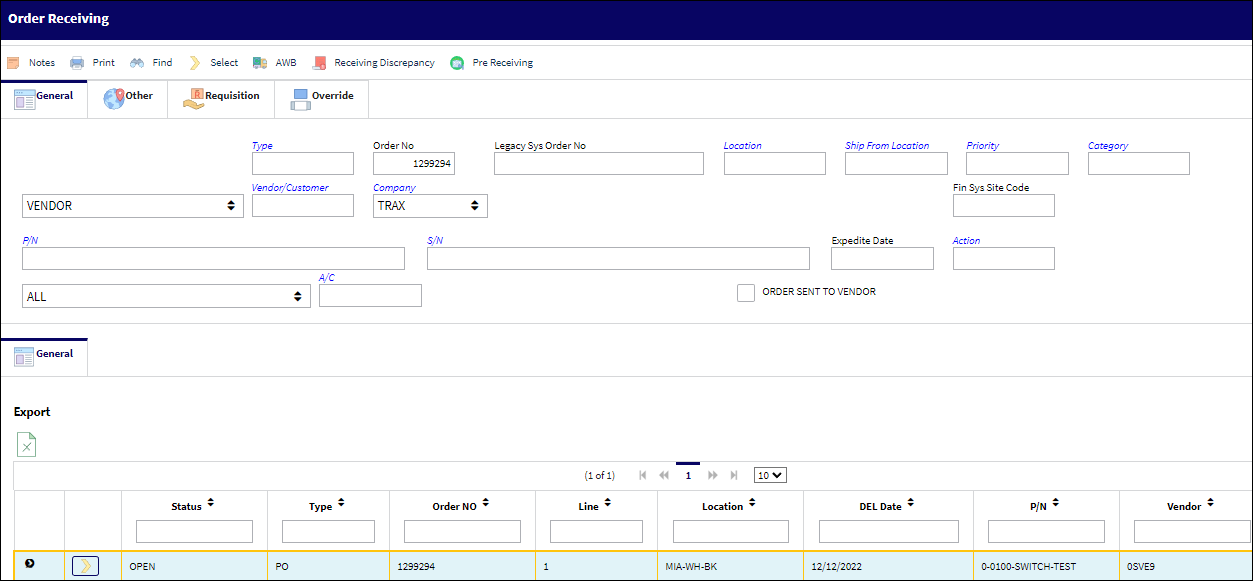

From Order Receiving, select the order to complete the order receiving process.

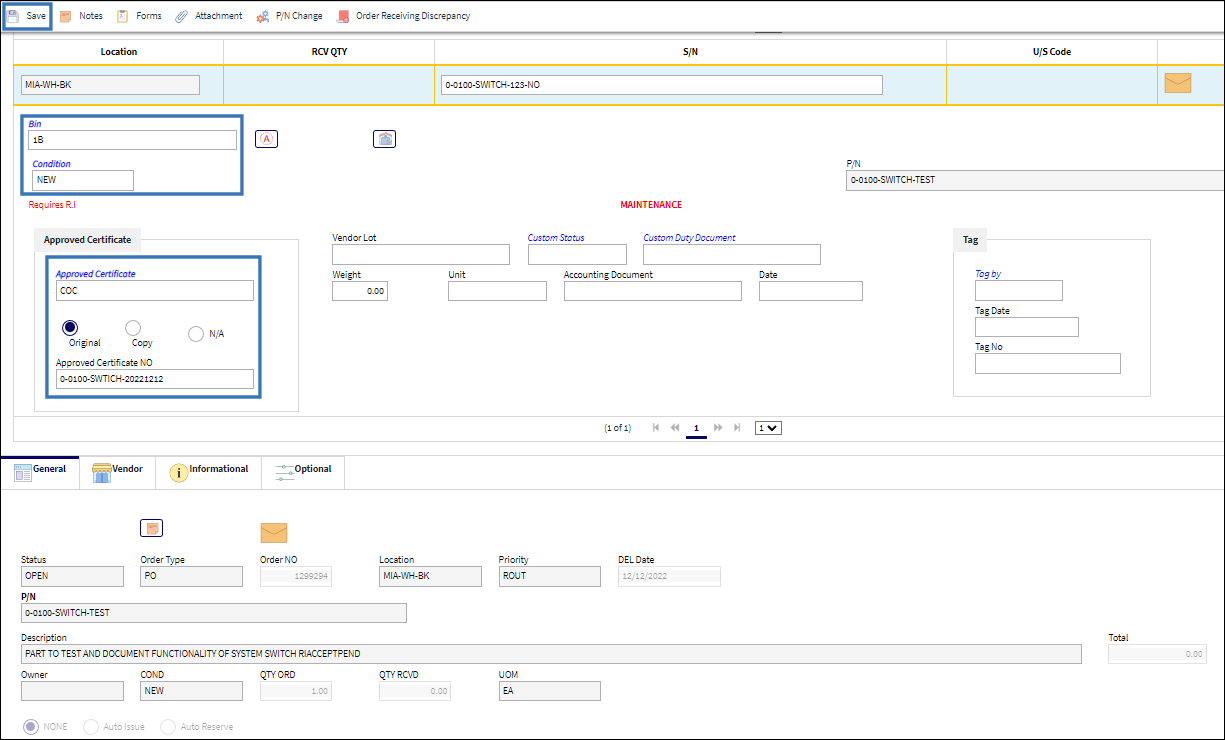

Perform and document the receipt information (e.g., bin, condition, and CoC or other documentation) and save the record.

A pop-up dialog presents with a soft warning to print a barcode label for the item. Select the appropriate radial button Yes or No and submit the response.

The P/N Control Dialog for the print queue will now populate with options to select/add or deselect part number controls. Respond as required and save the record.

From the menu pathway Receiving, Update, Receiving Inspection, select the record again. See below.

The Receiving Inspection record for PO 1928284 will again populate. Select the ![]() Tear Down button to complete the bench check inspection for the new part.

Tear Down button to complete the bench check inspection for the new part.

If the part is acceptable, select Accepted radial button, and then click the ![]() Control-E/C button to access the list of P/N Engineering Controls.

Control-E/C button to access the list of P/N Engineering Controls.

From the Control screen for P/N engineering controls, select or deselect the required controls, enter any additional information and save the record.

In the Tear Down Report window, select a Confirm code for type of confirmation performed, add detail as required and save the transaction.

Notice that the Tear Down Report record transaction was successfully saved.

Notice from the Inventory Transaction window that the item is still in Receiving Inspection status.

The record for the part may now be selected to Unlock/change it to an available status in inventory from the Receiving Inspection window. Click on the Unlock ![]() button in the part number record to execute this action. The record may only be unlocked/authorized for available inventory, after all order receiving requirements for the part number's receipt, labeling, engineering controls and Tear Down Report are complete as set in the P/N master.

button in the part number record to execute this action. The record may only be unlocked/authorized for available inventory, after all order receiving requirements for the part number's receipt, labeling, engineering controls and Tear Down Report are complete as set in the P/N master.

Once unlocked, select the Receiving record again. Check the Accepted radial button and save the record.

A Label Print dialog box populates. Select the Yes or No radial button as required and Submit the response.

Notice from the Inventory Transaction window that the status for the ordered part has changed from Receiving Inspection to Available in inventory.

Share

Share

Print

Print