Share

Share

Print

Print

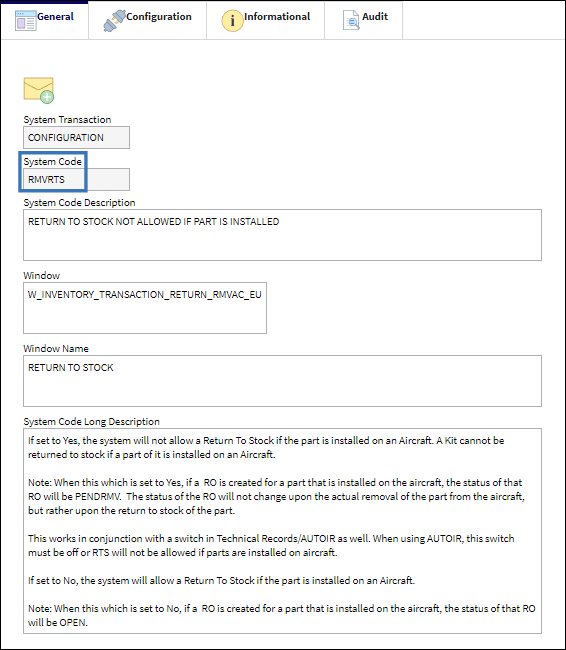

RMVRTS - Return To Stock Not Allowed If Part Is Installed On Aircraft

Return To Stock Not Allowed If Part Is Installed On Aircraft

Affected Window: w_inventory_transaction_return_rmvac_eu

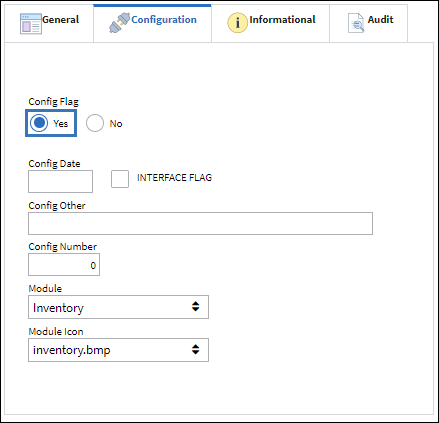

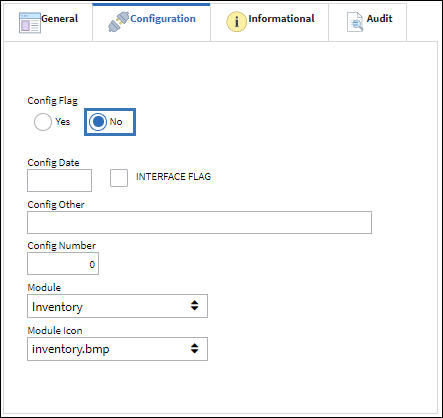

Switch Set to Yes:

When set to Yes, the system will not allow a P/N to be Returned To Stock if the P/N is installed on an A/C.

Note: Additionally, a Kit cannot be returned to stock if a part of it is installed on an Aircraft.

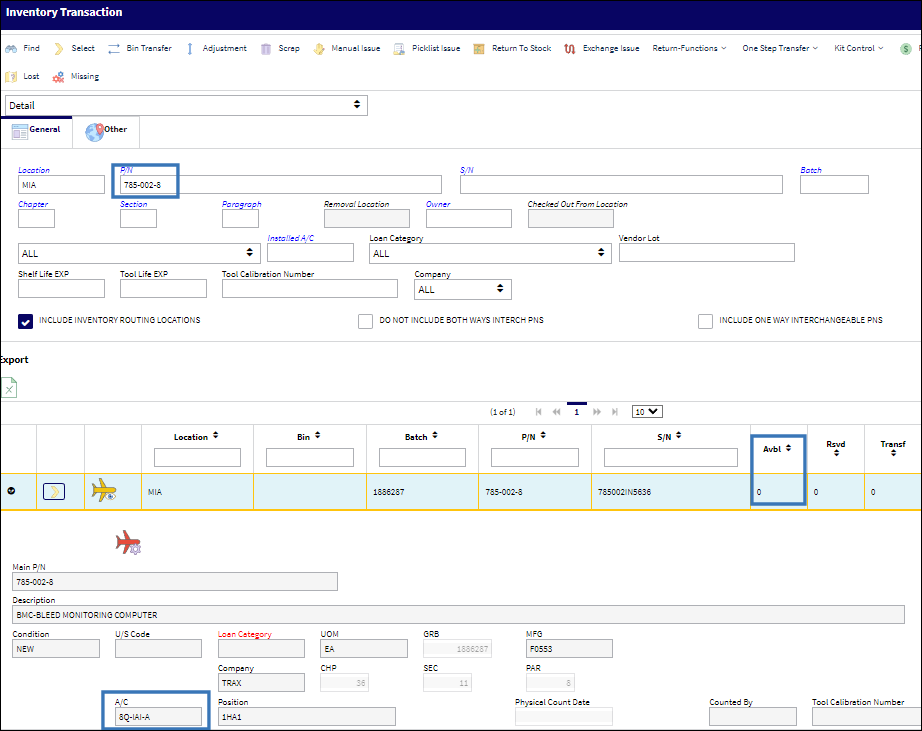

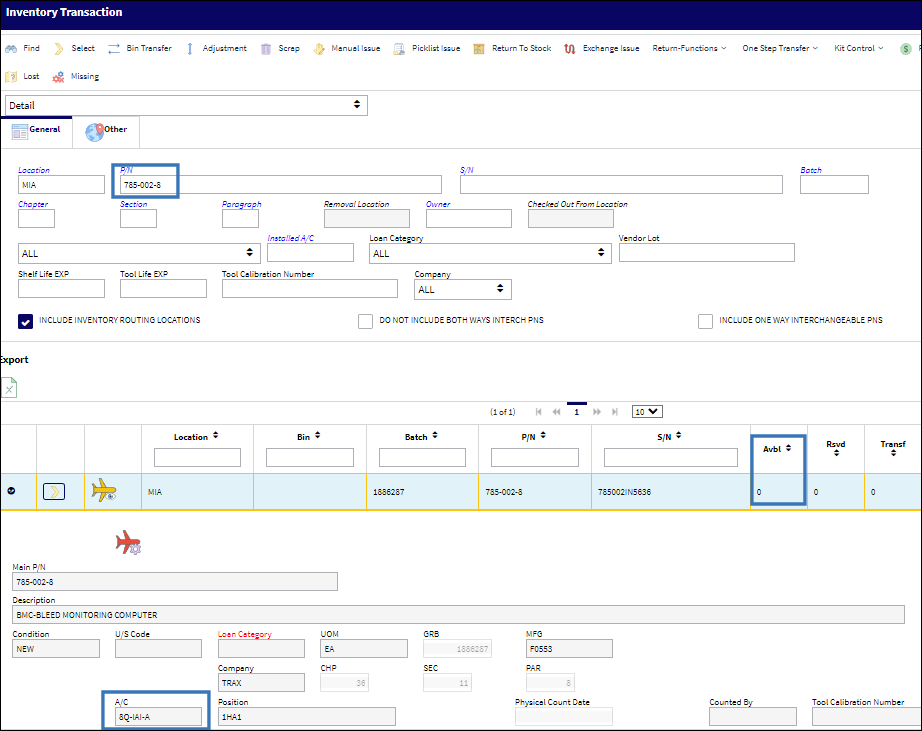

The following is an Inventory Transaction for a P/N that has been installed on an A/C. Notice that zero (0) units are available in inventory and the part is currently installed on the aircraft.

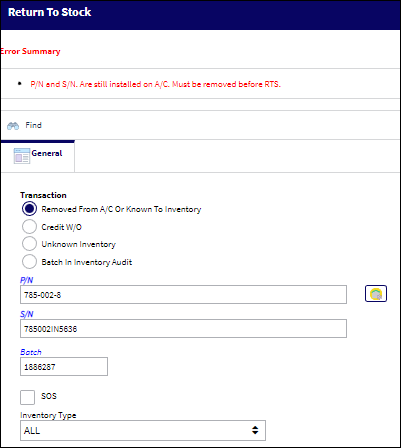

With the switch set to Yes, select the Return To Stock ![]() button. Notice that the P/N is not able to be returned to stock because it is installed on an A/C.

button. Notice that the P/N is not able to be returned to stock because it is installed on an A/C.

Note: When this Switch is set to Yes, if a R/O is created for a part that is installed on the aircraft, the status of that R/O will be PENDRMV. The status of the R/O will not change upon the actual removal of the part from the aircraft, but rather upon the return to stock of the part.

Switch Set to No:

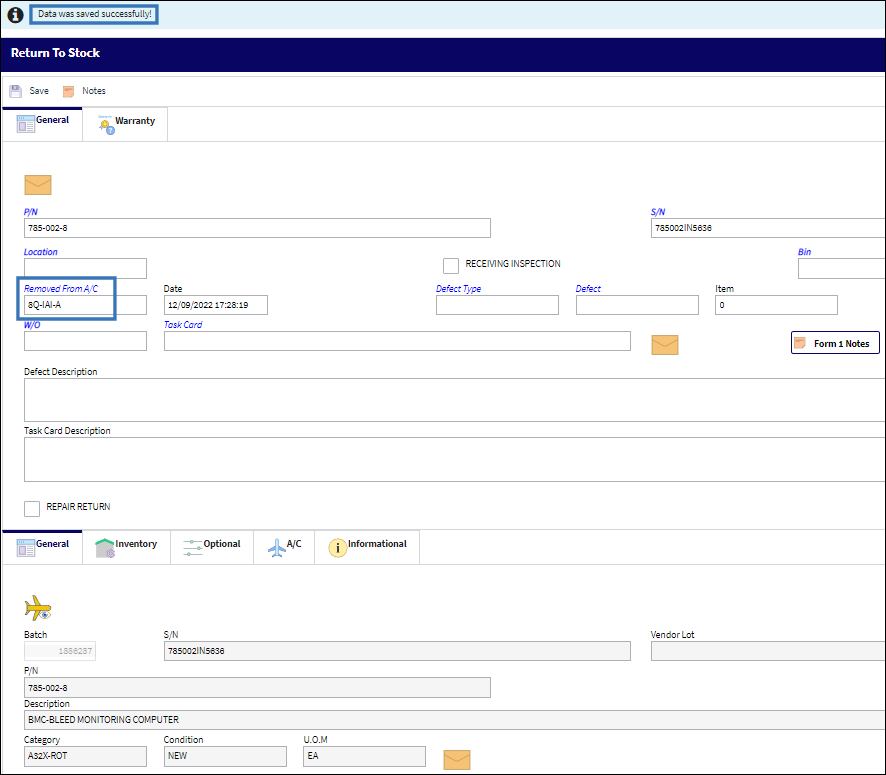

When set to No, the system will allow a P/N to be Returned To Stock, even if it is installed on an A/C.

The following is an Inventory Transaction for a P/N that has been installed on an A/C. For this example, the same aircraft part which previously generated an error will be used.

With the switch set to No, after selecting the Return To Stock ![]() button, the P/N is returned to stock, even if installed on an aircraft.

button, the P/N is returned to stock, even if installed on an aircraft.

Note: This Switch is available to allow RTS of parts when the Technical Records module is not currently being used. This switch works in conjunction with the Technical Records Switch ![]() AUTOIR. When using AUTOIR, this switch must be set to No or RTS will not be allowed if parts are installed on aircraft.

AUTOIR. When using AUTOIR, this switch must be set to No or RTS will not be allowed if parts are installed on aircraft.

Share

Share

Print

Print