Share

Share

Print

Print

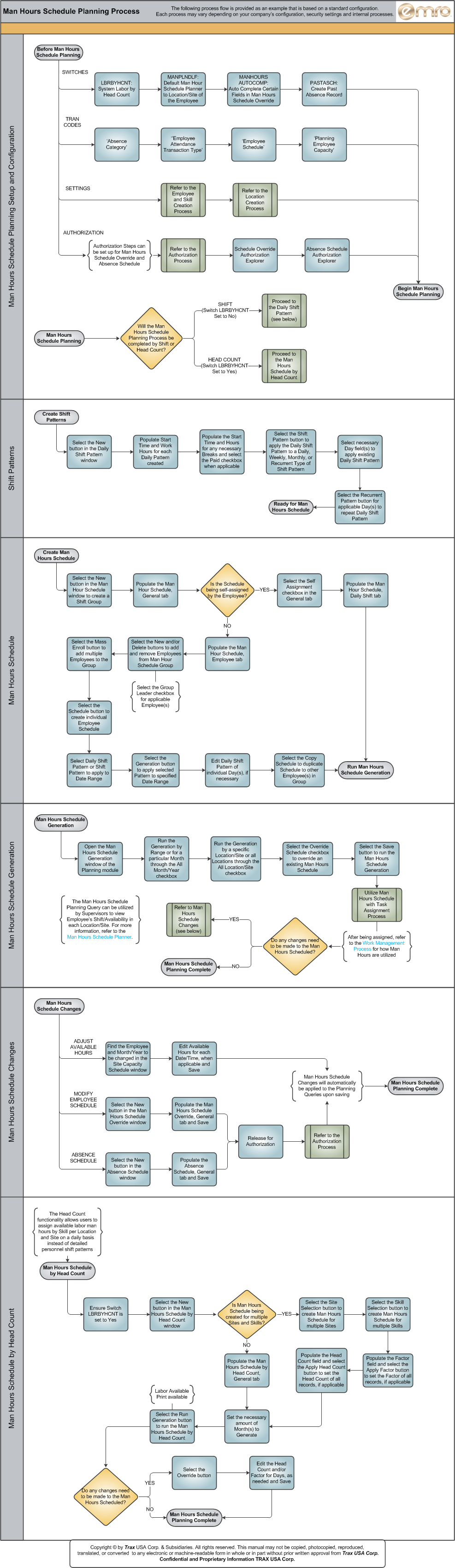

Man Hours Schedule Planning Process

The Man Hours Schedule Planning features allows for the set up of all Man Hour Schedules with the option of specifying shift work patterns. This feature generates the employee shift pattern, which is then used when the employees are associated to that shift at a specific location. The information is then used to calculate the available work capacity. This available work capacity is then used for the labor reservation upon the creation of planned maintenance events associated via the Work Order and Location combinations. In addition, once employees have been assigned to their shifts, the employee may attain their schedule through various Planning prints; while management may view the Employee's Work Load Planner via the Employee Master.

Utilizing Switch ![]() LBRBYHCNT allows the user to conduct Man Hours Schedule by Head Count, which conducts Employee Planning primarily according to Location and Skill.

LBRBYHCNT allows the user to conduct Man Hours Schedule by Head Count, which conducts Employee Planning primarily according to Location and Skill.

The following process flow is a general guide for the configuration, creation of shifts and schedule, generation, and changes to the Man Hours Schedule Planning. This life cycle may vary depending on each user and their company's customized protocols.

The following sections are the primary elements covered in this process flow:

- Man Hours Schedule Planning Setup and Configuration

- Shift Patterns

- Man Hours Schedule

- Man Hours Schedule Generation

- Man Hours Schedule Changes

- Man Hours Schedule by Head Count

Share

Share

Print

Print