Share

Share

Print

Print

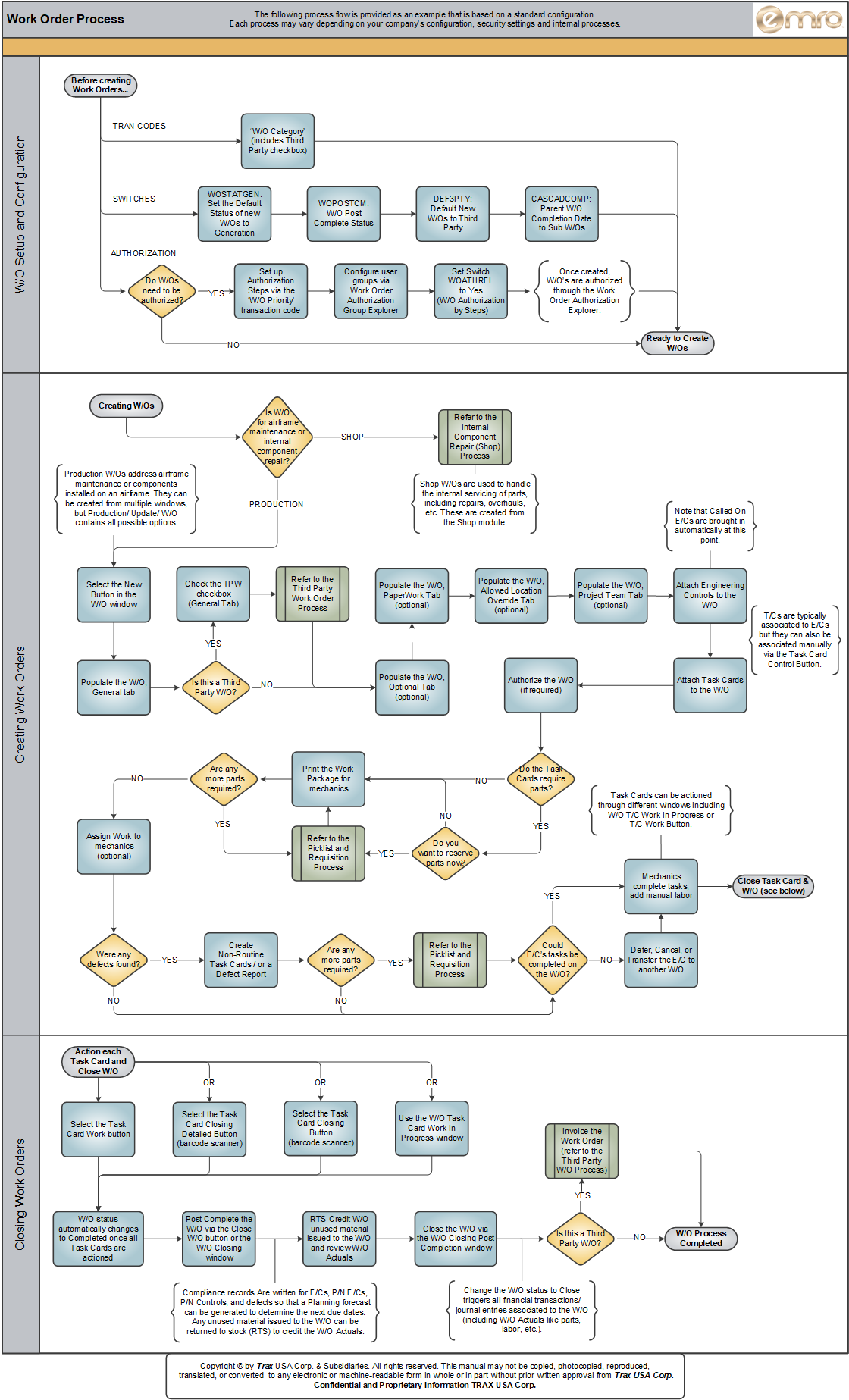

Work Order Process

The Production module is responsible for the creation and management of work conducted on aircraft mainframes. The Work Order is the main option used in the Production system. This is used to create and manage the work packs for the aircraft. This work can be categorically internal as well as third party.

Note: The Shop module is used for internal work (repairs, refurbishing, etc.) on off-wing parts.

An additional element of the Work Order functionality is it allows the company to analyze all time and costs involved in the work, giving a better understanding of the operation and the opportunity to improve in certain areas where cost and time are an issue.

Work can be planned effectively and work packs can be created quickly, avoiding labor intensive copying and sorting of Task Cards (Check Cards). Relevant information to the checks is produced along with the Check Pack to allow project management of the check.

Third Party capabilities allow management of projects for your customers, giving you full flexibility and control over your costs and charges to your customers. System invoicing is immediate, detailing all work carried out and any materials used. Additional billing can be added to include miscellaneous costs.

Finally, upon completion of Work Orders (checks, etc.), information is fed back to other modules in the system, such as Technical Records (for component information), Engineering (completions of inspections, AD's, SB's etc.) and the G/L Interface (for costing and billing).

Bar coding can be used for shop floor data collection, allowing online, real-time recording of work carried out. Graphical statuses of each check can be viewed while work is in progress. Management can easily see when work is ahead, on time, or behind schedule (actual versus estimates), along with the breakdown of costs involved.

The following process flow is a general guide for the configuration, creation, and closing of the Work Order life cycle. This life cycle may vary depending on each user and their company's customized protocols.

The following sections are the primary elements covered in this process flow:

- W/O Setup and Configuration

- Creating Work Orders

- Closing Work Orders

Share

Share

Print

Print