Share

Share

Print

Print

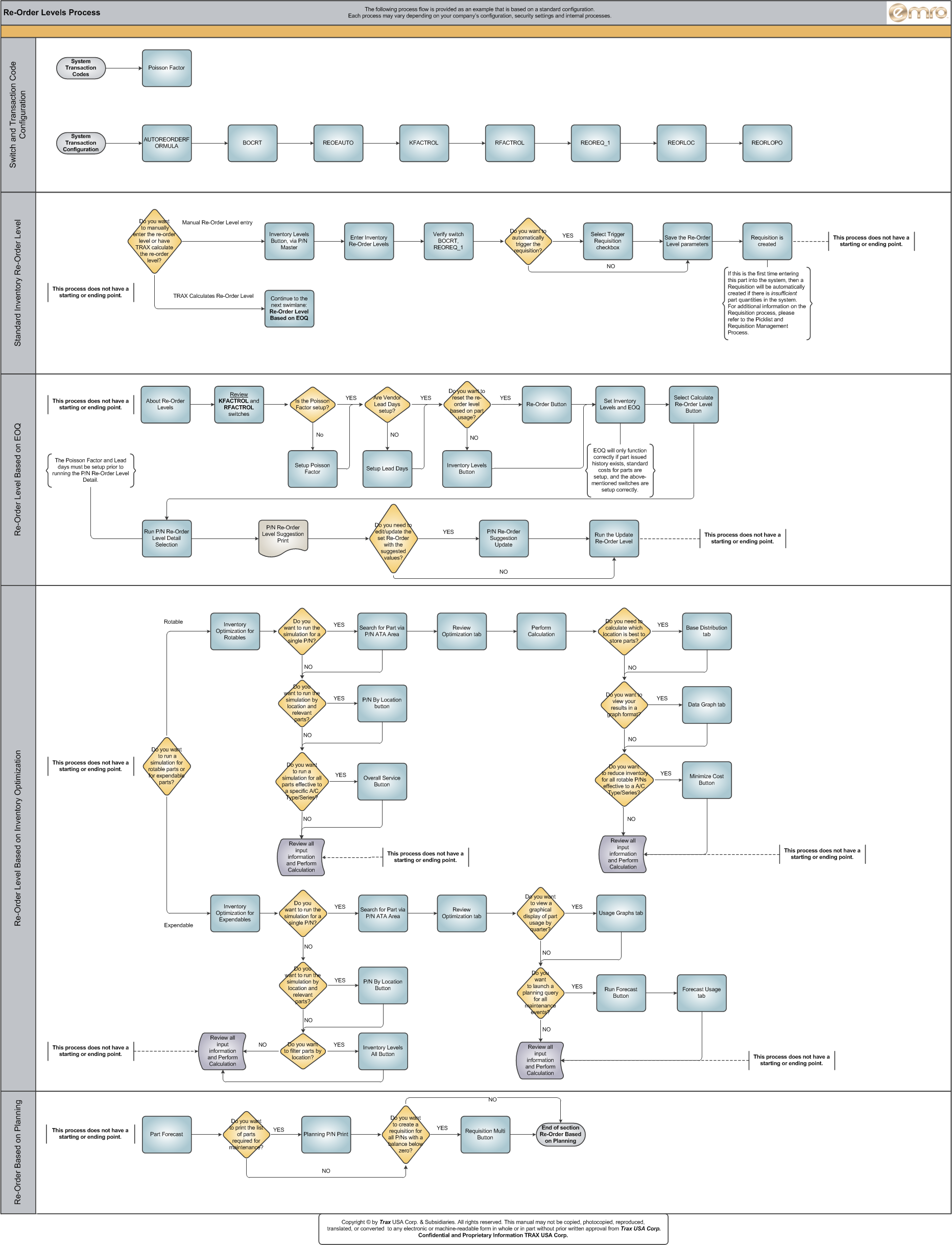

Re-Order Level Process

Inventory Management requires constant re-ordering of parts when parts are running low in stock or are no longer in stock. The system utilizes a standard Re-Order Level formula which helps minimize cost by forecasting the optimal times that part quantities will require replenishment. The system provides different methods, depending on your business processes, on how to set up and track part re-order levels.

The Re-Order Level Process will demonstrate four separate step-by-step methods for Inventory Management. It will demonstrate how to set up a standard re-order level for parts, how to set up a re-order level based on the Economic Order Quantity (EOQ), how to set up a re-order level based on the Inventory Optimization tool and how to re-order based on Planning.

Share

Share

Print

Print