Share

Share

Print

Print

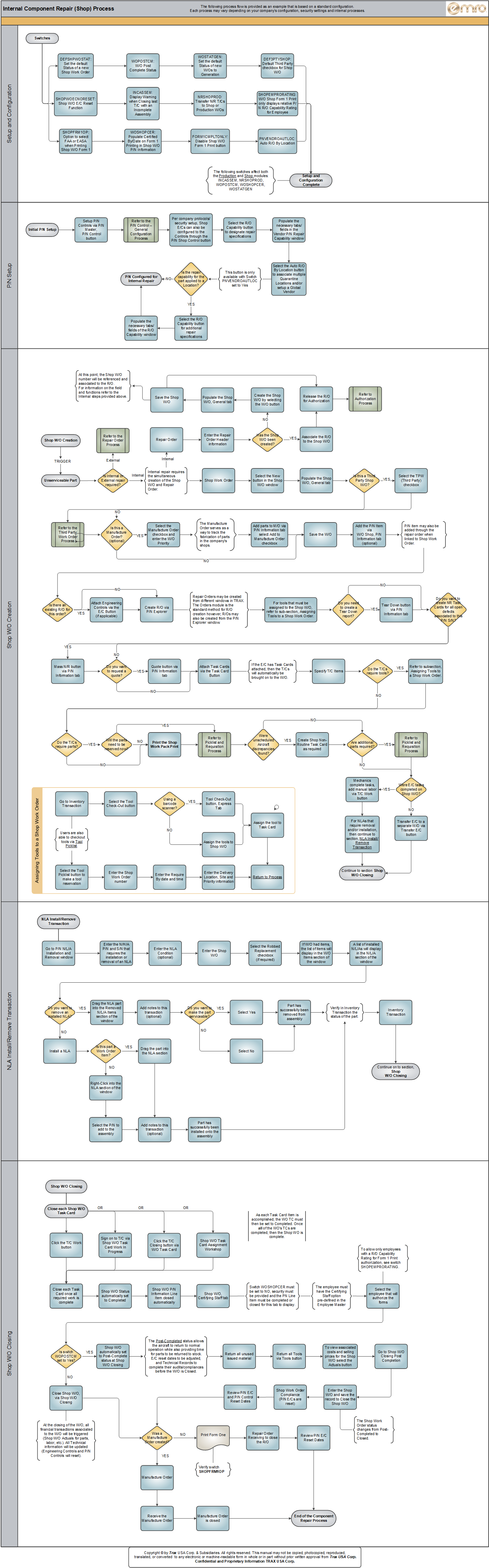

Internal Component Repair (Shop) Process

The Shop module is responsible for the creation, management, and tracking of maintenance/repair work performed on parts. Internal repair capabilities are covered in the Shop module.

This work can be categorized as internal (for components owned and utilized by users) or Third Party (for components utilized by third party customers but repaired by users).

The Production module is used for work done on aircraft while the Shop module is used for work on parts.

An additional element of the Shop Work Order allows the company to analyze all time and costs involved in the work, giving a better understanding of the operation and the opportunity to improve in certain areas where cost and time are an issue.

Shop work can be planned effectively and work packs can be created quickly, avoiding labor intensive copying and sorting of check cards. Relevant information to the checks is produced along with the check pack to allow for project management of the check.

Reports detailing work requirements and zone conflicts help to organize the check effectively. Panel removal sheets cut down on the time wasted on removing/installing panels unnecessarily.

This module's Third Party capabilities give you the tools to manage customer projects, and all associated costs and charges efficiently. System invoicing is immediate and details all materials used and work performed. Miscellaneous costs can also be included by using the Additional Billing feature

Bar coding can be used for shop floor data collection, allowing for online, real time recording of carried out work. Graphical representations of each check's status can be viewed while work is in progress. Managers can see when work is ahead or behind schedule (actual versus estimates), alongside breakdowns of associated costs at a glance.

The Barcode 3 of 9 Regular font (BARCD39.ttf) must be installed in your Windows/ Fonts directory in order for you to have the ability to view barcodes (where available) in specific reports throughout the system. Please contact your System Administrator to confirm that this font has been correctly installed.

Included as part of the Shop module is the interface to your financial system, which allows complete cost control of checks and dissemination of work in progress costs against work completed.

Finally, upon completion of Shop Work Orders, completion information is fed back to other modules in the system, such as Technical Records (for component information), Engineering (completions of inspections, AD's, SB's etc.) and the Accounts interface (for costing and billing).

The (creation of the) Shop Work Order is the main option available in the Shop module and is used to create and manage the work packs for the components and aircraft.

The Internal Component Repair Process is a general guide for the configuration, creation and completion of the Shop Work Order life cycle. The following process is designed to outline all the steps required in order to create, complete and close Shop Work Orders.

Share

Share

Print

Print