Share

Share

Print

Print

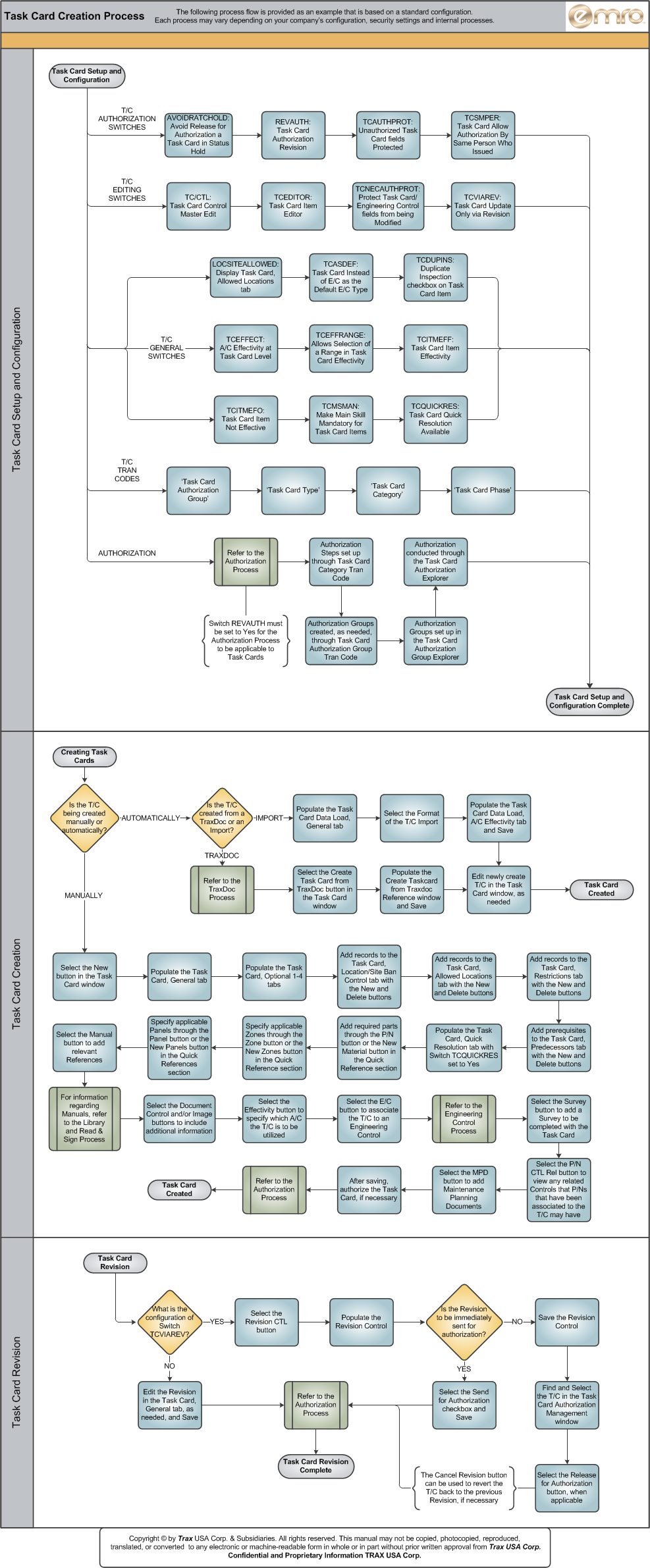

Task Card Creation Process

The Engineering module is used to manage Task Cards Task Cards (or Work/Job Instruction Cards) are used to enter all the information required to carry out work on a component or aircraft as well as individual components. This includes reporting on Aircraft AD/SB status and compliance history.

Additional information that is linked to the Task Card provides benefits such as pre-loading part lists, effectivity, documentation requirements (maintenance manuals and other documents), work zones, panels needing removal and the individual steps required to carry out the task by trade. Digital Documentation can be printed along with the task cards.

Manpower requirements are entered into the Task Cards and this information is then used by the Production system and the Planning module to forecast capacity and to allow reservation of labor workforce against work to be carried out.

Task Card authoring allows for the integrated use of AMM or other digital documentation within the Task Card itself (e.g. tasks can be created solely of AMM references which are updated automatically in line with the AMM revision process).

The following process flow is a general guide for the configuration, creation, and revision of the Task Card life cycle. This life cycle may vary depending on each user and their company's customized protocols.

The following sections are the primary elements covered in this process flow:

- Task Card Setup and Configuration

- Task Card Creation

- Task Card Revision

Share

Share

Print

Print