Share

Share

Print

Print

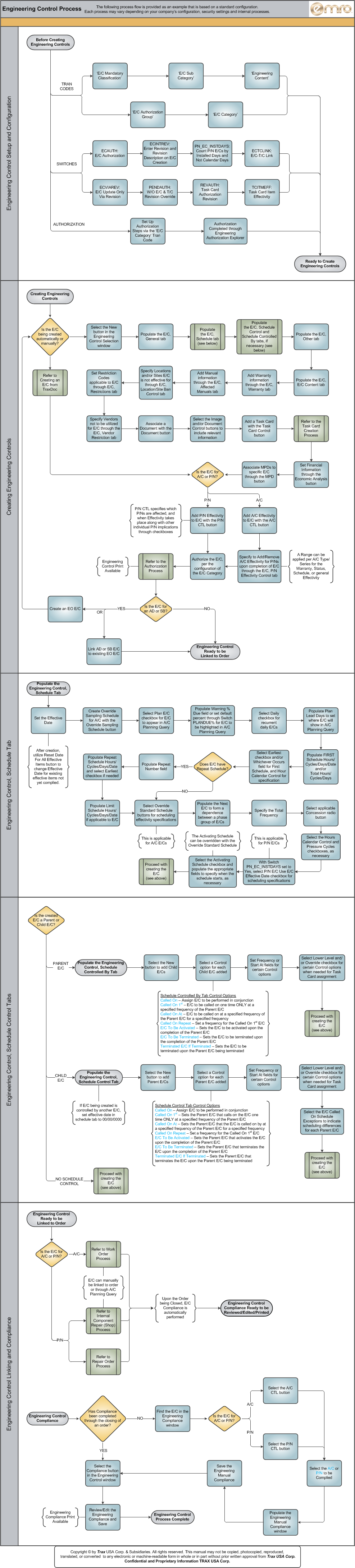

Engineering Control Process

The Engineering module is used to manage Engineering Controls (E/Cs) and Task Cards for aircraft, as well as individual components. This includes reporting on Aircraft AD/SB status and compliance history.

Engineering requirements can be loaded both manually and electronically into the system. The system allows the user to track ADs, SBs and modifications for aircraft and their components, including revision control and multiple schedules. Task Cards with work requirements can also be created in this module, as well be scheduled alongside routine aircraft work. Manufacturers' electronic documentation can be loaded, viewed and printed online (for example, AMM pages for inclusion with work packages).

Information from the Engineering module is used in many other areas of the system. The Planning module is very much dependant on information from the Engineering Controls. Reports and queries can easily be produced to interrogate the Engineering information stored in the system. Reports regarding compliance and cost are readily available for the Aviation Authorities and management. Information from Engineering is fed through to the Production system, for calculating ground times for inspections and creating work packs for aircraft.

The following process flow is a general guide for the configuration, creation, linking and compliance of the Engineering Control life cycle. This life cycle may vary depending on each user and their company's customized protocols.

The following sections are the primary elements covered in this process flow:

- Engineering Control Setup and Configuration

- Creating Engineering Controls

- Engineering Control, Schedule Tab

- Engineering Control, Schedule Control Tabs

- Engineering Control Linking and Compliance

Share

Share

Print

Print