Share

Share

Print

Print

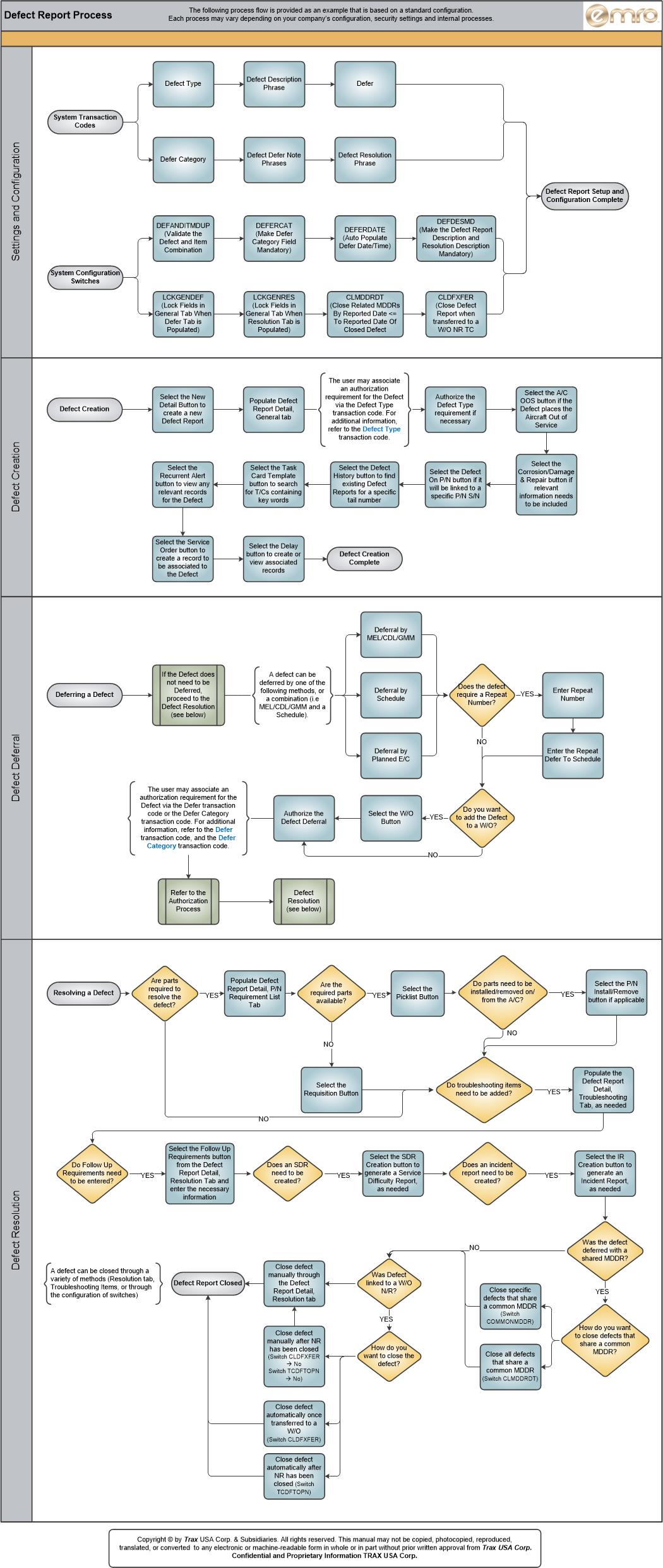

Defect Report Process

Defects are considered to be unscheduled maintenance events. This is the opposite of a Work Order which is a scheduled maintenance event. Defects are usually created last minute before an aircraft takes off.

Discrepancies occurring during line operations are recorded in the operator’s logbook system, which may include separate Maintenance and Cabin Logs. Commonly, operators consolidated these logs into one log referred to as the Aircraft Logbook. This log is used to record discrepancies encountered during operation of the airplane and the actions taken to correct the discrepancies. The aircraft logbook is reviewed and cleared. At a minimum, malfunctions affecting airworthiness are either repaired or deferred under the Minimum Equipment List (MEL).

Within the system, the Defect Report is the electronic equivalent of the Aircraft Logbook. This option allows the user to enter the aircraft Defect discrepancies into the system. Defect Reports could help correct a wide range of discrepancies affecting the aircraft, including: simple repairs, work which is necessary to keep the aircraft airworthy without incurring a flight delay or cancellation, and the removal and replacement of line replacement units (LRU).

Defect Reports can be deferred and closed at a later date. Part number transactions can be carried out with the entry of a Defect Report.

The Defect option can be accessed from the A/C Actual Flight Entry option.

The data entered against Defect Reports, combined with P/N removals, is the basis for Reliability reports on the system.

Note: This program can be wall security protected. The user will then have to enter their wall password before being able to enter a new defect report.

To activate this feature, go to System Administration/ Update/ Control Panel/ Technical Records/ Defect Report. Select the Wall checkbox to enable the wall password protection. For additional information regarding the wall password and how to set it up, refer to Security Explorer, Wall by Program via the System Administration Training manual.

The Defect Report process is designed to allow users to visualize the entire procedure for creating a Defect Report.

Each step in the process chart is explained in further detail throughout the following documentation. The procedural sections are broken down into the following categories:

- Settings and Configuration

- Defect Creation

- Defect Deferral

- Defect Resolution

Share

Share

Print

Print