Share

Share

Print

Print

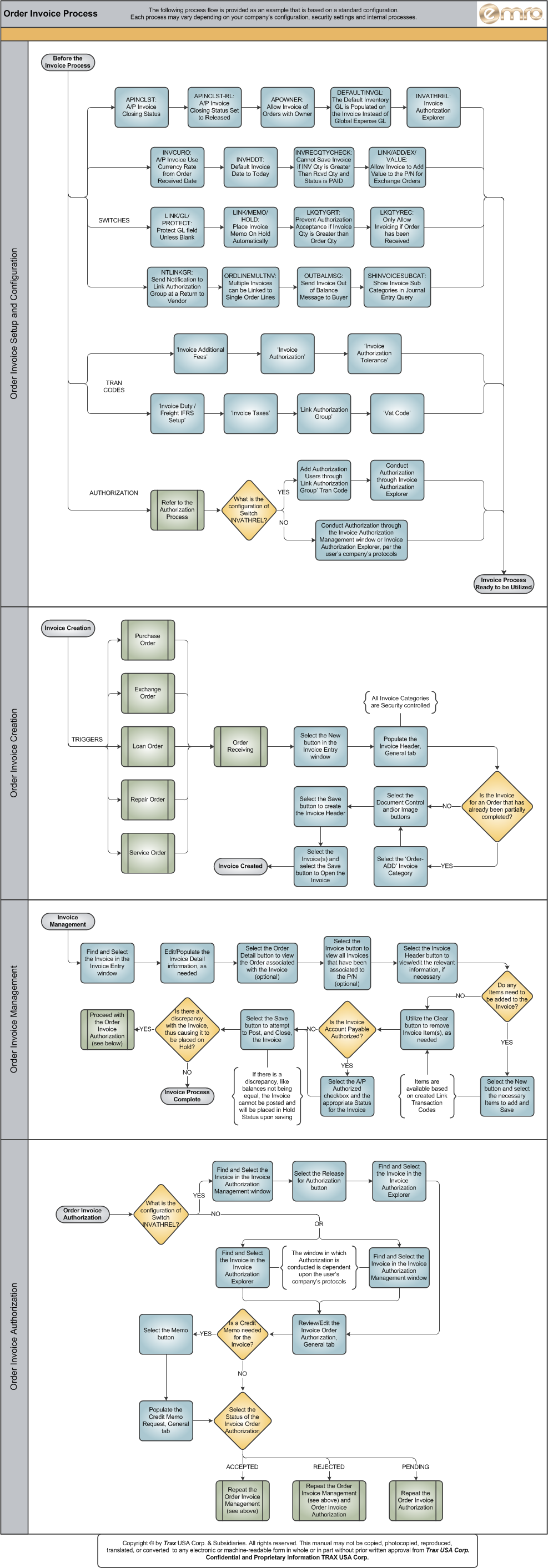

Order Invoice Process

The purpose of the Link module is to allow the entry, update, and reporting of received invoices related to orders that have been placed through the system. It allows for the confirmation of order fulfillment, price match of order to invoice and accuracy of invoicing. Any discrepancies are processed via an exception queue.

Note: This module does not contain Accounts Payable functionality.

Order types that are routinely invoiced are as follows:

- Purchase Order

- Exchange Order

- Loan Order

- Repair Order

- Service Order

Once an invoice is received (from a vendor or outside source), it may be entered into the system via the Link module. The entry of this invoice is for a number of purposes (i.e. traceability of stock cost and value).

It should be noted that this functionality is not an Accounts Payable system and does not provide Accounts Payable functionality. The Link module is a recording and reporting system, and has the capability of feeding the recorded information into a separate A/P system via a program interface. The transfer to an A/P system is done via G/L Interface/Update/Invoice Transfer to A/P. Please refer to the G/L Training Manual for more information.

Invoices for parts can be entered before the parts have a receiving record. Reports can also be produced to show parts that have arrived and are not yet invoiced (Orders/ Print/Invoice Print).

Multiple currencies are supported. For example, a part can be purchased in one currency, received and converted into two supported system currencies, and then invoiced in another currency. Fluctuations in currency value are taken care of by adjustment journal entries following invoicing.

If an invoice has been posted, it may not be re-opened, deleted, or modified. However, if an invoice is on ‘Hold’ status, it may be re-opened, deleted, or modified. Once a particular invoice is posted, a new invoice must be created and the Credit/Debit Memo functionality must be used to make any adjustments to that invoice.

If the user receives an invoice for an order and the quantity of parts received does not match the quantity of parts on the order, the user will use the Order – ADD functionality to adjust and account for the transaction. If an order has already been paid (via an invoice) and posted, the user can make adjustments to the transaction with the Memo functionality.

The following process flow is a general guide for the configuration, creation, management, and authorization of the Order Invoice life cycle. This life cycle may vary depending on each user and their company's customized protocols.

The following sections are the primary elements covered in this process flow:

- Order Invoice Setup and Configuration

- Order Invoice Creation

- Order Invoice Management

- Order Invoice Authorization

Share

Share

Print

Print