Share

Share

Print

Print

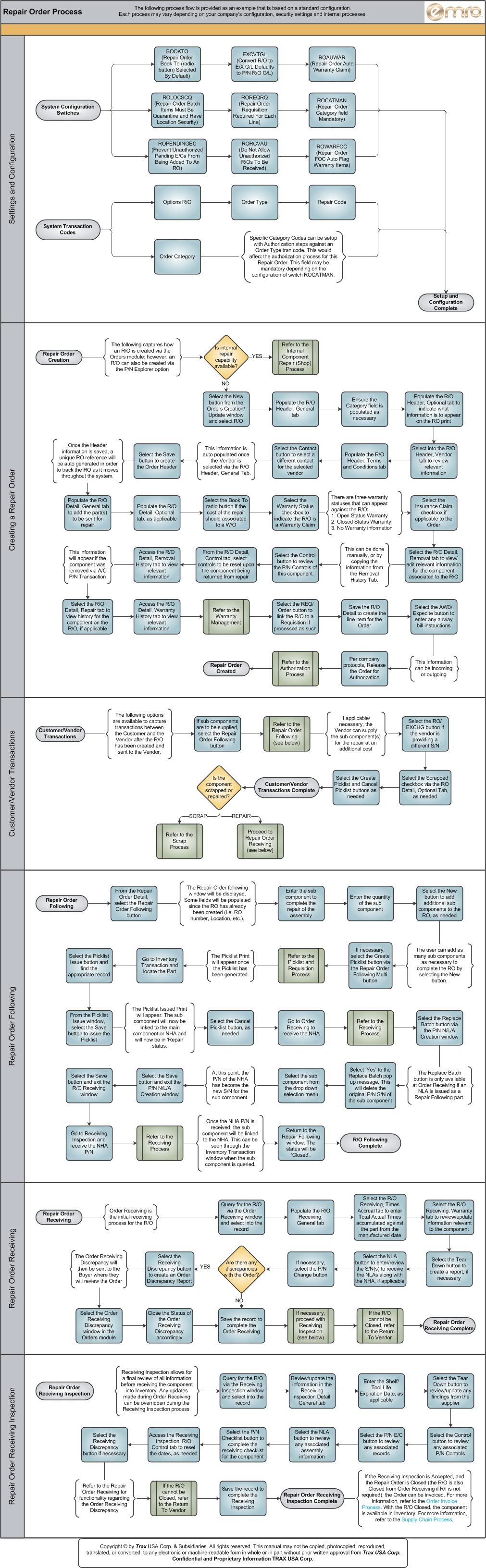

Repair Order Process

A Repair Order can be created following the receipt of quotations and work specifications if required (according to company policy). This option will allow you to create and update a Repair Order for a part that will be either sent away to a vendor or internal shop. This may be for repair, modification, testing, or any other category (as defined via Settings/ Explorer/ System Transaction Code/ Orders/ Repair Code). Once a Repair Order is created, it will go through an initial Order Receiving process. If there are any discrepancies with the order, an Order Discrepancy Report can be generated and the order can be sent back to the supplier, or it may continue through the Order Receiving process. Once the Order Receiving process has been completed, the Repair Order will go to 'Closed' status, however the component will be not yet be available in Inventory if the component requires a secondary receiving process: Receiving Inspection. During the Receiving Inspection process any updates made during Order Receiving will be reviewed and can be overridden at this time. After the Receiving Inspection process has been completed, the component will be available in Inventory.

The Repair Order process is designed to allow users to visualize the entire procedure for creating a Repair Order and receiving it into inventory.

Each step in the process chart is explained in further detail throughout the following documentation. The procedural sections are broken down into the following categories:

- Repair Order Settings and Configuration

- Creating a Repair Order

- Repair Order Receiving

- Repair Order Receiving Inspection

Share

Share

Print

Print