Share

Share

Print

Print

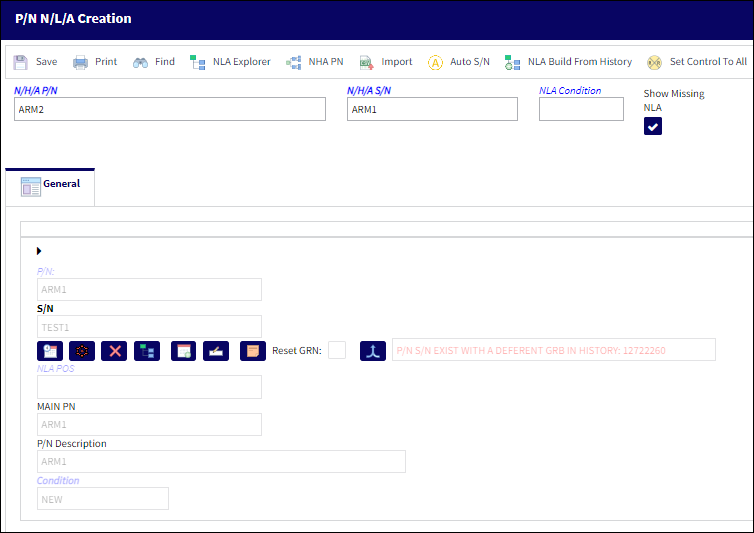

P/N N/L/A Creation

The P/N N/L/A Creation option allows users to create or modify P/N assemblies and sub-assemblies. This window is primarily utilized when building the assembly during the process of bringing the component(s) into the system. Users can modify P/N Controls, view related notes, and delete parts from the assembly as necessary.

Enter a valid N/H/A Part Number and Serial Number and select the Find ![]() button.

button.

The above fields should be reviewed for the assembly's sub-components (NLAs). To modify an N/L/A, select the Edit ![]() button.

button.

The following fields and options are available:

_____________________________________________________________________________________

Save ![]() button

button

Select the Save button to create a Serial Number record for the N/L/A P/N. A Serial Number cannot be created for an N/L/A P/N if the S/N record exists in Inventory.

Note: To add an existing N/L/A S/N to an N/H/A, refer to the N/L/A S/N ![]() button below.

button below.

N/H/A P/N

The part’s Next Higher Assembly P/N (if applicable).

N/H/A S/N

Next Higher Assembly (NHA) serial number.

NLA Condition

The condition of the N/L/A being received. Once the condition has been populated, it will cascade down to all of the N/L/A components.

Show Missing NLA checkbox

When this checkbox is selected, it allows the user to view all installed and missing N/L/As on an assembly. This checkbox is selected by default upon opening the P/N N/L/A Creation window.

P/N

The Part Number reference for the aircraft part. The Next Lower Assembly component that is being updated. Multiple P/Ns will be listed as N/L/As for the assembly.

S/N

The Serial Number for the specific serialized part. The Serial Number of the Next Lower Assembly components.

N/L/A Position

The position of the Next Lower Assembly. This position indicates where the N/L/A is to be installed in the assembly.

MAIN P/N

The NLA's Main P/N in the Part Number Master. This field is only necessary if the NLA component is an interchangeable with a main component.

Condition

The current Condition of the Next Lower Assembly component.

Shelf Life Expiration

Updates the shelf life expiration date of the part. For more information, refer to the Override ![]() button below.

button below.

Reset GRN checkbox ![]()

Select the Reset GRN checkbox to override the previous goods received number (Goods Received Batch) and have the system automatically create a new GRN for this part after the transaction is completed. This is useful if an assembly is sent for repair and is returned with a new lower component. If the Reset GRN checkbox is checked, a new GRN is created. This will have the system create a new history for the assembly and not associate the new lower component with the history of the prior assembly.

Merge GRB ![]() button

button ![]()

Select this button to merge a part history to a P/N S/N via a new Goods Received Batch number. Once processed, the P/N will retain the pre-existing history (Transaction History, A/C P/N Transaction History, P/N Total Times, etc.) that the part once had in the system. This is useful for instances in which a part is being reintroduced via P/N N/L/A creation and the system needs to preserve the part history rather than create a new one. For more information refer to Merge GRB Button, via P/N N/L/A Creation.

P/N Control ![]() button

button

Select this button to update the NLA's P/N Inventory Controls.

Note: Once this button has been selected, and any changes have been made and saved, the button will change from blue to red.

P/N E/C ![]() button

button

Opens the P/N E/C selection window where users can create or edit E/Cs for the selected part. For more information, refer to the P/N E/C Button via the Receiving Training Manual.

![]() Note: The Select checkbox, Complied checkbox, Revision field, Status field, and Reset Date field each are security controlled via Receiving/ Update/ Receiving Inspection/ P/N E/C Selection. For more information, refer to the Security Explorer via the System Administration Training Manual.

Note: The Select checkbox, Complied checkbox, Revision field, Status field, and Reset Date field each are security controlled via Receiving/ Update/ Receiving Inspection/ P/N E/C Selection. For more information, refer to the Security Explorer via the System Administration Training Manual.

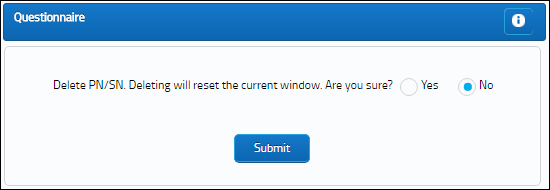

Delete ![]() button

button

Select the Delete ![]() button to delete the selected N/L/A Serial Number from the assembly then enter a new Serial Number in its place. The new P/N S/N does not have to currently exist in inventory. A history record will be written for the new part.

button to delete the selected N/L/A Serial Number from the assembly then enter a new Serial Number in its place. The new P/N S/N does not have to currently exist in inventory. A history record will be written for the new part.

Note: The deleted P/N S/N will be removed from inventory.

The following prompt will appear. The user will be asked to confirm your request.

Select Yes. The user will be required to enter a new Serial Number for the specific deleted N/L/A. The P/N Assembly Explorer will indicate that the Serial Number (part) is missing from the assembly until a new Serial Number is input and saved.

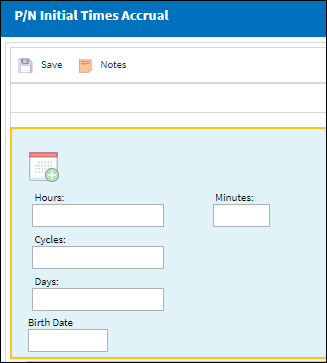

Times Accrual ![]() button

button

When this button is selected, the P/N Initial Times Accrual window appears. For additional information, refer to the P/N Initial Times Accrual button, via the Inventory Training Manual.

Edit ![]() button

button

Select this button to edit the N/L/A position and N/L/A condition. Upon selecting the edit button, the P/N, S/N, N/L/A Position and Condition fields will be cleared out and available for update.

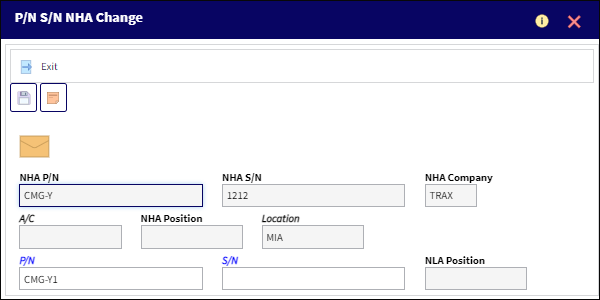

NLA S/N ![]() button

button

The N/L/A S/N button allows users to select an existing Serial Number for the N/L/A P/N in the assembly. The selected N/L/A P/N must be at the same Location and installed on the same A/C as the N/H/A P/N (if the N/H/A is installed on an A/C). This button will only be available if an S/N has not been selected for the N/L/A P/N.

![]() Note: The system will only allow users to select a Serial Number for the missing N/L/A P/N.

Note: The system will only allow users to select a Serial Number for the missing N/L/A P/N.

Notes ![]() button

button

Select this button to view a note(s) added to the N/L/A as part of receiving.

Override ![]() button

button

When selected, the Shelf Life Days in the P/N Master, Inventory tab is Overridden by 365 days of the entered date. For more information, refer to P/N Master, Inventory Tab via the Settings Training Manual.

Replace Batch ![]() button

button

Select this button to replace an existing PN S/N Batch with the new P/N S/N that was added to the assembly via a Repair Following transaction. This button is part of the Repair Following functionality (optional in the Repair Order process) and is only available when a Repair Following transaction took place during the repair. For more information, refer to the Repair Following Button via the Orders Training Manual.

_____________________________________________________________________________________

The following buttons offer additional functionality:

- Print Button

- NLA Explorer Button

- NHA PN Button

- Removed Part Tag Print Button

- Import Button

- Auto S/N Button

- NLA Build From History Button

- Set Control To All Button

Share

Share

Print

Print