Share

Share

Print

Print

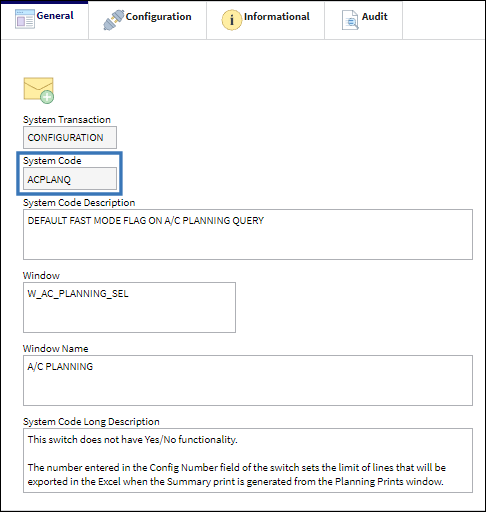

ACPLANQ - Number of Lines When Planning Prints Summary is Exported As Excel

Number of Lines When Planning Prints Summary is Exported As Excel

Affected Window: w_ac_planning_sel

Note: This switch does not have Yes/No functionality, however, it must be set to Yes for functionality to work as expected.

The number entered in the Config Number field of Planning Module switch (ACPLANQ) sets the maximum number of rows that may be exported via a report to Excel for specific Reports/Module. Otherwise, the system will limit Excel reports to 5,000 rows/Excel worksheet report. This switch is programmed to override the hard-coded 5,000 rows/report limitation for reports that are so configured.

The Switch ACPLANQ may be configured to generate more than 5,000 worksheet rows for the following Reports:

Inventory Module, Inventory Detail Print window

- Tool Life Expiration

- Shelf-Life Expiration

- Shelf-Life Expiration Detail

- Shelf-Life Expiration Detail with NLAs

- Inventory Calendar Control

Planning Module, Planning Prints window:

- The Summary Report

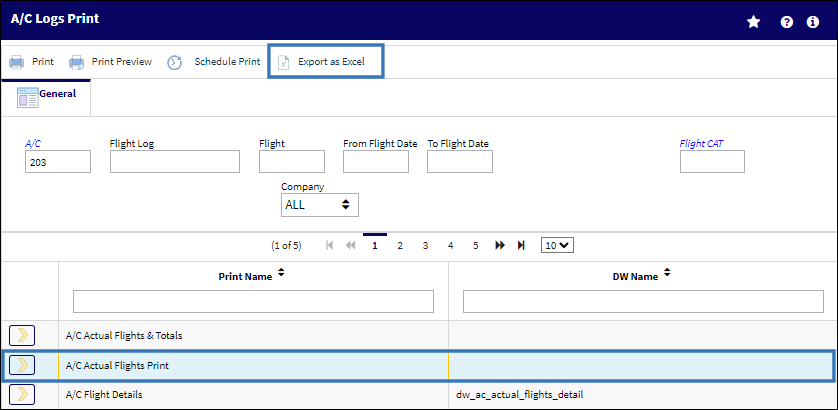

Technical Records Module, A/C Logs Print:

- A/C Actual Flights Print

- Engine Utilization Report

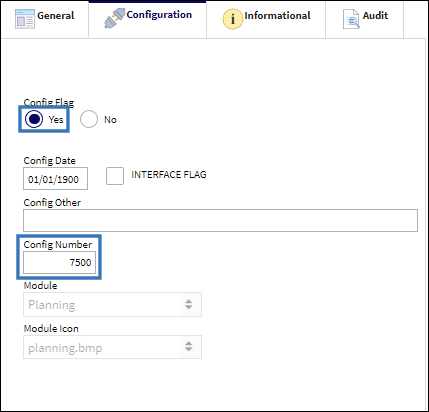

Switch set to Yes:

In the example below, the switch is set to Yes and the Configuration Number is set to 7500. For any reports configured to override the hard coded system limit of 5,000 rows/report, the system will generate a consolidated report with records/rows up to the Config Number set.

From the relevant window, select the applicable report, then select the Export as Excel ![]() button. The report may be recovered from the system's Print's queue.

button. The report may be recovered from the system's Print's queue.

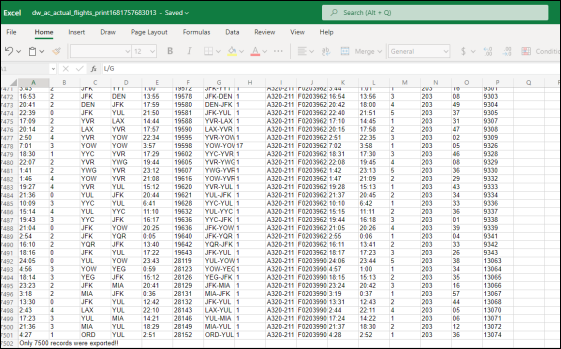

Notice that the Excel spreadsheet produced below was limited to 7500 rows because the Config Number for the switch was set with this limitation.

Share

Share

Print

Print