Share

Share

Print

Print

The MTCM creates T/Cs for Bombardier fleets (CRJs and Dash). The manufacturer for this manual is Bombardier.

From the TraxDoc Document Detail, General tab, select the Import From OEM ![]() button.

button.

When uploading a document into TraxDoc, the file that is being uploaded must be in a location where the eMRO server will recognize it. See below instructions:

- The IT department on the user side must select a directory to work as a repository for all the OEM manuals that would be uploaded to eMRO via the TraxDoc module.

- This directory must be accessible from the application server (Wildfly).

- Create a way for users to provide the OEM manual revisions to be placed in the repository.

- The path for the repository directory will be defined by the traxdoc_manual variable on the data.source.properties file. This can be found under the application server (/%WILDFLYHOME%/deployments/emro.war/WEB-INF/classes/resources/).

SaaS customers should refer to the instructions outlined in this document in iCentral: SaaS - How to Upload TraxDoc Manuals.

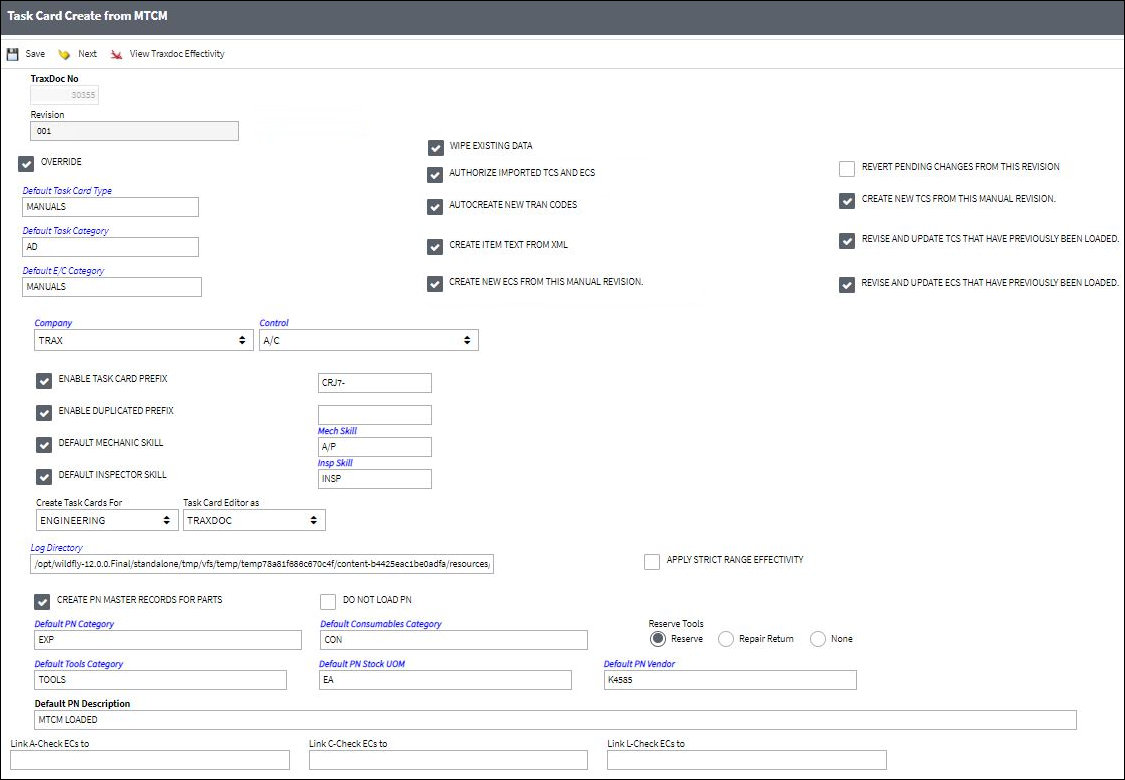

The system displays the Task Card Create from MTCM window which allows Bombardier Task Cards to be loaded.

The following information/options are available in this window:

_____________________________________________________________________________________

TraxDoc No.

The TraxDoc Document ID number, which is automatically generated by the system.

Revision

The document’s current revision number. Each TraxDoc can have multiple revisions as the data/records created through the TraxDoc will need to be updated (revised) regularly depending on the requirements of the aircraft manufacturer, regulatory agency, airline, etc.

Override checkbox

Select this checkbox to override the Revision for Task Cards that are being imported.

Wipe Existing Data checkbox

Select this checkbox to replace the existing data with the data from the new revision.

![]() This checkbox is security controlled via TraxDoc/ Update/ TraxDoc Master/ Wipe Data on Update.

This checkbox is security controlled via TraxDoc/ Update/ TraxDoc Master/ Wipe Data on Update.

Authorize Imported TCs and ECs checkbox

Select this checkbox to automatically authorize all Task Cards and ECs created.

Autocreate New Tran Codes checkbox

Some of the Task Card information provided in OEM manuals is controlled by Tran codes (i.e. Task Card types, areas, and skills). Selecting this checkbox will automatically create a Tran code record for any values found in the manual. If this box is not checked, the fields will still be set in the Task Card, but will have to be changed manually when working with the task card. This option is unchecked by default.

Create Item Text from XML checkbox

Select this checkbox to have the imported XML file create text for the imported Task Card Items.

Revert Pending Changes from this Revision checkbox

Select this checkbox to revert pending changes to the revision. Any new Task Cards created for this revision will also be deleted.

Create New TCs from this Manual Revision checkbox

Select this checkbox to create new Task Cards from the current manual revision.

Revise and Update TCs that have Previously been Loaded checkbox

Select this checkbox to revise and update Task Cards that have previously been loaded.

Create New ECs from this Manual Revision checkbox

Select this checkbox to create new Engineering Controls from the current manual revision.

Revise and Update ECs that have Previously been Loaded checkbox

Select this checkbox to revise and update Engineering Controls that have previously been loaded.

Default Task Card Type

The Task Card Type. This is useful in the sort and locating of the Task Card.

Default Task Category

Select the Task Card Category to be assigned to all Task Cards being created/revised from this import. Task Card Category will delegate the authorization process and send notifications as defined in the System Transaction Codes.

Default E/C Category

Select the E/C Category to be assigned to all Task Cards being created/revised from this import. The E/C Category will delegate the authorization process and send notifications as defined in the System Transaction Codes.

Enable Task Card Prefix checkbox

Select this checkbox to allow a prefix to be assigned to Task Cards being imported.

Task Card Prefix - The prefix to be assigned to the T/C being imported.

Enable Duplicated Prefix checkbox

Select this checkbox to allow a duplicate prefix to be assigned to Task Cards being imported.

Duplicated Prefix - A duplicate of the prefix to be assigned to the T/C being imported.

Default Mechanic Skill checkbox

Select this checkbox if the mechanic skill is mandatory. The Default mechanic skill field will become mandatory once this checkbox is selected.

Default Mechanic Skill - The default mechanic skill for the Task Card items created if this is not supplied by the OEM manual.

Default Inspector Skill checkbox

Select this checkbox if the inspector skill is mandatory. The Default inspector skill field will become mandatory once this checkbox is selected.

Default Inspector Skill - The default inspector skill for the Task Card items created if this is not supplied by the OEM manual.

Create Task Cards For drop down

Select the module required to load the SGML Task Card to: Engineering, Shop, GSE.

Log Directory

This option allows the user to specify the directory to which log files and error reports will be saved. The initial value is a sub-folder inside the default temporary directory.

Apply Strict Range Effectivity checkbox

When checked, imported Task Cards/Engineering Controls will be made effective to all Aircraft Type/Series, regardless of whether or not tail-level effectivity is specified in the manual. Positions, Zones, Panels, References, etc. will also be created for all type/series. If unchecked, effectivity will only be created for those type/series that have a least one effective Aircraft specified in the manual.

Create PN Master Records for Parts checkbox

Select this checkbox to auto create records in the P/N Master for any parts found in the manual.

When this checkbox is selected, the following fields appear:

Default PN Category - This P/N Category field in this window is referring to only Expendable and Consumable part numbers. This determines how the system will handle this part. If the Category entered is Expendable or Consumable, the system will be expecting either an Expendable or Consumable number for every item in the system for this part number.

Default Consumables Category - This P/N Category field in this window is referring to only Expendable and Consumable part numbers. This determines how the system will handle this part. If the Category is a 'non-serialized' or a 'kit' type then the system will not be expecting serial numbers for every item.

Default Tools Category - This P/N Category field in this window is referring to Tool part numbers. This determines how the system will handle this part. A Tool P/N Category can be defined as serialized or non-serialized. If serialized, the system will be expecting serial numbers for every item in the system for this part number. The user must enter default values to place in these fields in case the AMM does not contain data for them. Parts for this category are identified by the TOOLNBR tag.

Default PN Stock UOM - The ATA code for Unit Of Measurement (or internal code if preferred). The Order UOM differentiates by Stock UOM a unit of conversion may be defined in the UOM code which will automatically convert the Order UOM to the Stock UOM at receiving.

Default PN Vendor - The Manufacturer or main Vendor for this part. The Vendor must be flagged in the Vendor Master as a Manufacturer to populate this field.

Default PN Description - The description of the part number.

Do Not Load PN checkbox

When this checkbox is selected, the system will not load the P/Ns against the Task Card(s) created with the import.

Reserve Tools - Select from one of the following radio buttons:

Reserve radio button - Select this button to reserve the spare or tool when W/O P/N reservation is applied.

Repair Return radio button - Select this button to repair/return the spare when W/O P/N reservation is applied.

None radio button - Select this button if no spare or tool has been reserved or repaired.

Task Card Editor

The editor that will be used to edit Task Card information.

TRAXDOC - The TRAXDOC Editor uses uploaded Style Sheets in TRAXDOC as a template for the Task Card print; Task Cards for each TRAXDOC can have a different layout based on the criteria of the TRAXDOC Style Sheet (i.e. fleet type, customer). The TRAXDOC Editor is not a RTF Editor. When TRAXDOC Editor is selected, a TraxDoc No field appears to enter the TraxDoc reference number.

Link A-Check ECs To

Certain E/Cs are specified in the manual as being part of an A-Check. This optional field allow the user to specify the E/C to which these manual E/Cs will be linked. By doing so, the user is assigning the manual E/Cs a parent E/C and employee the Engineering Control, Schedule Control Called On Functions. For additional information, please refer to the Engineering Control, Schedule Control Tab section of the Engineering Training Manual.

Link C-Check ECs To

Certain E/Cs are specified in the manual as being part of a C-Check. This optional field allow the user to specify the E/C to which these manual E/Cs will be linked. By doing so, the user is assigning the manual E/Cs a parent E/C and employee the Engineering Control, Schedule Control Called On Functions. For additional information, please refer to the Engineering Control, Schedule Control Tab section of the Engineering Training Manual.

Link L-Check ECs To

Certain E/Cs are specified in the manual as being part of an L-Check. This optional field allow the user to specify the E/C to which these manual E/Cs will be linked. By doing so, the user is assigning the manual E/Cs a parent E/C and employee the Engineering Control, Schedule Control Called On Functions. For additional information, please refer to the Engineering Control, Schedule Control Tab section of the Engineering Training Manual.

_____________________________________________________________________________________

Note: Effectivity can also be reviewed through the View MTCM Effectivity ![]() button.

button.

![]() Note: Skill match is enabled for data generated through this import. Task Cards generated via this import will have the mechanic skill set as default and their inspector skills pulled from the associated profile skill.

Note: Skill match is enabled for data generated through this import. Task Cards generated via this import will have the mechanic skill set as default and their inspector skills pulled from the associated profile skill.

Bombardier Re-Structured T/C Loader:

In order for the Bombardier T/C loader schema for aircraft Q400 and CRJ-705/900 to be loaded correctly, the Category of the TraxDoc must be set to 'MTCMQ400'. This Category is hard-coded to communicate with the upgraded .JAR file. As such, users must create a new TraxDoc Category transaction code called 'MTCMQ400.

Note: Changing the Category of an existing TraxDoc is not enough to update the new Bombardier loader schema. A new TraxDoc must be created with this Category and JAR file.

Further, a JAR file from 06/03/2014 or more recent must be applied to the TraxDoc load. The JAR files from this date onward will contain the required enhancements needed to communicate with the updated Bombardier T/C loader schema. This necessary JAR file is included in the installer package, as usual.

Share

Share

Print

Print