Share

Share

Print

Print

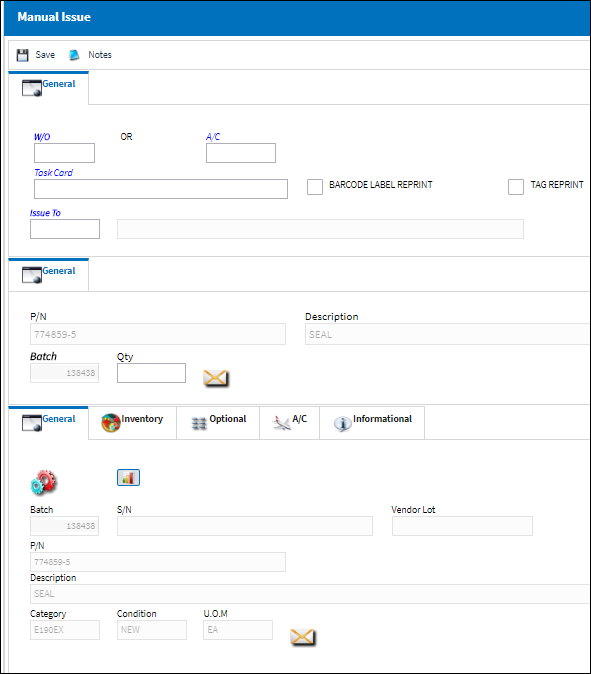

The Manual Issue functionality is used to issue parts ‘over the counter’ in order to keep the line maintenance routine running. These parts are not issued with a picklist and are thus handled with the Manual Issue functionality. For the majority of parts, the Picklist Issue option should be used.

From the Inventory Transaction window, find the part that needs to be issued then select the Manual Issue ![]() button. The system displays the Manual Issue window as follows. Populate all mandatory and desired information and select the Save

button. The system displays the Manual Issue window as follows. Populate all mandatory and desired information and select the Save ![]() button.

button.

![]() Note: The system will validate Manual Issue transactions to ensure the Company for the materials being issued matches the Company listed for the W/O or A/C. This validation prevents Company Inventory from being issued to a Third Party Work Order or A/C with a different Company by prompting an error message. In order for the transaction to be valid the materials being issued must match the Company on the A/C or the Third Party Work Order.

Note: The system will validate Manual Issue transactions to ensure the Company for the materials being issued matches the Company listed for the W/O or A/C. This validation prevents Company Inventory from being issued to a Third Party Work Order or A/C with a different Company by prompting an error message. In order for the transaction to be valid the materials being issued must match the Company on the A/C or the Third Party Work Order.

Note: A Manual Issue transaction cannot be performed for a part that has already been reserved against a picklist.

Note: The fields in the tabs in the lower portion of the window are informational.

![]() Note: When Inventory switch ISSUENLAKIT is set to Yes, the user can manually issue an N/L/K P/N that exists under an N/H/K if the N/L/K P/N is identified with a Loan Category and the vendor code populated in the Owner field. If the N/L/K P/N's Owner field is not populated, the user will not be able to issue the N/L/K P/N.

Note: When Inventory switch ISSUENLAKIT is set to Yes, the user can manually issue an N/L/K P/N that exists under an N/H/K if the N/L/K P/N is identified with a Loan Category and the vendor code populated in the Owner field. If the N/L/K P/N's Owner field is not populated, the user will not be able to issue the N/L/K P/N.

The following information/options are available in this window:

_____________________________________________________________________________________

W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

A/C

The individual aircraft tail number.

Task Card

The Task Card / Job Card that details the scheduled maintenance work.

ISSTCMAND - Make Task Card Mandatory in Picklist Creation/Manual Issue/Express Issue

ISSTCMAND - Make Task Card Mandatory in Picklist Creation/Manual Issue/Express IssueNote: If the W/O in which the Manual Issue is being performed against is Third Party, then the Task Card field will be Mandatory, appear bold and be required for the save of the record.

Issue To

The employee that the part is issued to. The Issue To may be configured to be mandatory and validate the employee’s status for issue.

ISSUETOC - Issued To – Use Employee Code Only

ISSUETOC - Issued To – Use Employee Code Only

Barcode Label RePrint checkbox

Select this checkbox to reprint the barcode label for this P/N at Manual Issue.

Tag RePrint checkbox

Select this checkbox to reprint the tag for this P/N at Manual Issue.

_____________________________________________________________________________________

Once a serialized part is Manual Issued to a W/O or Aircraft, that batch will be in Pending Technical Records ![]() status in the Inventory Transaction window.

status in the Inventory Transaction window.

NLA Effectivity:

If the user attempts to issue an APU part where the APU is effective to an aircraft, but its NLA does not have effectivity, the system will display an error.

![]()

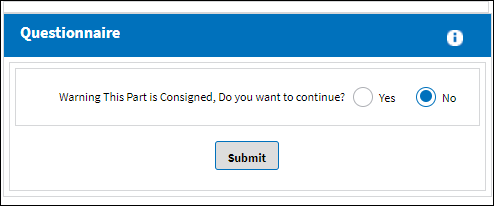

Issuing a Consigned Part Message:

If issuing a Consigned Part, the following soft warning will appear. For detailed information, refer to Issuing Consigned Inventory, via the Inventory Training Manual.

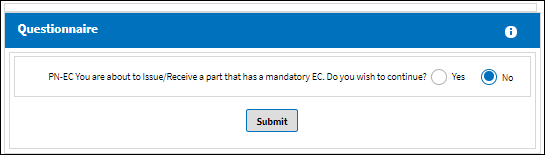

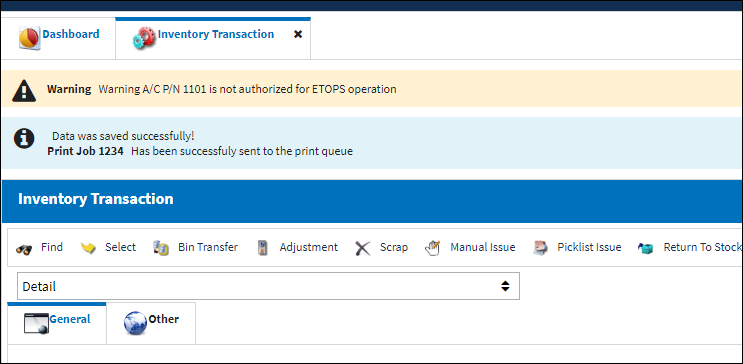

Issuing ETOPS Parts:

When attempting to manually issue (or complete any other type of transaction) a non authorized ETOPS P/N against an ETOPS's aircraft, the system issues a hard warning:

When attempting to manually issue (or complete any other type of transaction) a non authorized P/N against an ETOPS downgraded aircraft, the system issued the following soft warning and will allow the user to continue with the transaction:

![]()

When attempting to manually issue (or complete any other type of transaction) an ETOPS authorized P/N against an ETOPS downgraded aircraft, the system allows the user to continue with the transaction:

All ETOPS transactions will be recorded in the A/C Master Master window. For additional information, refer to the A/C Audit Button, via the A/C Master of the Settings Training Manual.

Additional information can be included through the Notes ![]() button.

button.

Share

Share

Print

Print