Share

Share

Print

Print

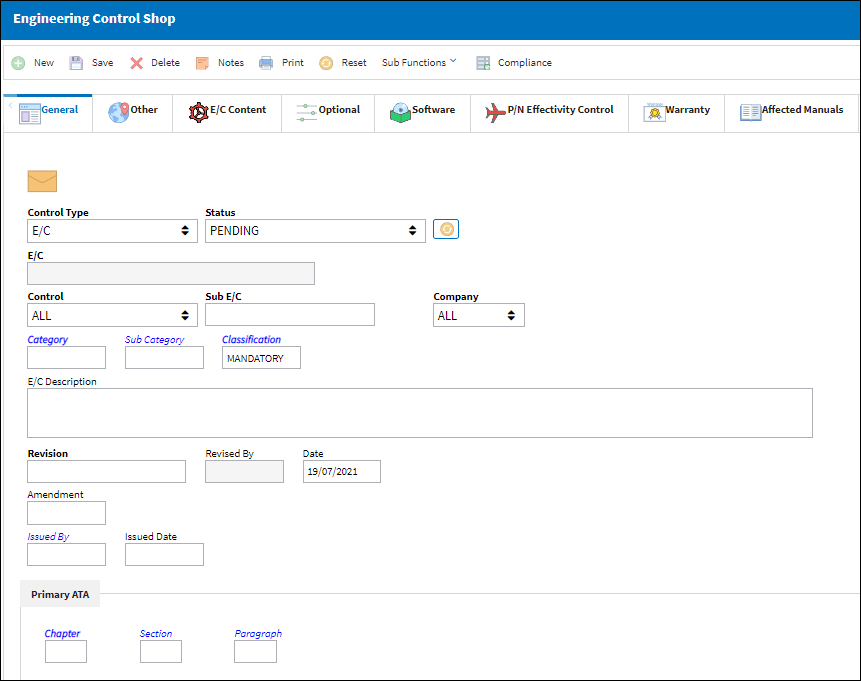

When creating a new Shop E/C, or updating an existing Shop E/C, the General tab is where the basic information regarding the Shop E/C is entered. Shop E/Cs will also be available to choose from the Repair Orders or via the Planning module.

Note: When creating a new E/C, if Switch ![]() ECINTREV is set to Yes, when the E/C is saved the revision window will pop up where the user will enter the revision description. The system does not allow the revision window to be closed without saving. If set to No, the revision window will not pop up.

ECINTREV is set to Yes, when the E/C is saved the revision window will pop up where the user will enter the revision description. The system does not allow the revision window to be closed without saving. If set to No, the revision window will not pop up.

Note: When creating a new E/C, if Switch ![]() ECSMPER is set to Yes, the system will allow the creator of the E/C to authorize their own E/C. If set to No, the user who created the E/C will not be able to authorize it.

ECSMPER is set to Yes, the system will allow the creator of the E/C to authorize their own E/C. If set to No, the user who created the E/C will not be able to authorize it.

Note: When updating an existing E/C, if Switch ![]() ECVIAREV is set to Yes, this will allow the E/C to be updated only upon E/C Revision (i.e. the E/C must go through the revision process for any changes). Additionally, if set to Yes, and the Config Other field is populated with 'PARTIAL,' the user will not have the ability to make changes to the General, Schedule, and Schedule Control Tabs. If the Config Other field is not populated with 'PARTIAL' then Switch

ECVIAREV is set to Yes, this will allow the E/C to be updated only upon E/C Revision (i.e. the E/C must go through the revision process for any changes). Additionally, if set to Yes, and the Config Other field is populated with 'PARTIAL,' the user will not have the ability to make changes to the General, Schedule, and Schedule Control Tabs. If the Config Other field is not populated with 'PARTIAL' then Switch ![]() ECAUTH must be set to Yes for the authorization process to work.

ECAUTH must be set to Yes for the authorization process to work.

The following information/options are available in this window:

_____________________________________________________________________________________

Control Type

The Engineering Control Type (E/C or Task Card). The Control Types have the same functionality throughout the system (i.e. planning, compliance, effectivity). The Control Type Task Card is used when creating an E/C schedule in order to link it to an existing Task Card (i.e. to apply a schedule to a standalone Task Card). The Control Type Task Card may also be used when importing an aircraft manufacturer's maintenance program into the system, based on the manufacturer's document format and settings selected by the user at the time of the import (i.e. if selections are made to import and create the E/Cs and Task Cards at the same time).

Note: If Switch ![]() TCASDEF is set to Yes, when creating a new E/C, the default E/C type will be 'Task Card' instead of 'E/C'. If set to No, E/C will be the default type.

TCASDEF is set to Yes, when creating a new E/C, the default E/C type will be 'Task Card' instead of 'E/C'. If set to No, E/C will be the default type.

Status

The status of the E/C. When creating a new E/C the initial status will default to Pending; if the user requires to hold this E/C until ready it can be left as Pending, or alternatively it can be changed to another status.

When an E/C Status is changed, the status, in most cases, cascades down to the E/C effective items. For more information refer to E/C Status Cascade Functionality via the Engineering - E/C Training Manual.

The following Status options are available:

Applicable/Not Embody - The E/C is applicable to an A/C Type/Series or Part Number, but may not be mandatory. This status allows the E/C to be entered in the system, but does not require compliance.

Cancel - The E/C has been cancelled.

N/A - The originating document (AD, SB, MOD, etc.) has been evaluated and is deemed not effective to a specific A/C or P/N.

Open - The E/C is Open.

Pending - This is the default status. This will be the status until the E/C is authorized. If the user requires holding this E/C until ready, it can be left as Pending even after the record has been saved. Once the E/C is authorized the status will show as Open.

Rejected - The E/C was rejected or not authorized and may need to be sent back through the authorization process for revision. This status should not be selected manually.

Terminated - The E/C is no longer in use. It has either been complied with for all effective aircraft or components, or the action of another E/C has terminated it. When an E/C is terminated, the termination applies to the entire fleet. This status should not be selected manually.

Note: Users can receive an email or notes message when any action is performed against an E/C by setting up the notifications through the E/C Category System Transaction Code. For more information, refer to the E/C Category Notification via the Settings Training Manual.

Reset Status for All Effective Items ![]() button

button

This buttons allows users to select which effective individual items (aircraft or components) to have the Status cascaded down to. The status will cascade to the selected items even if they are overridden at the individual effectivity level. When selected, the Multi A/C P/N S/N window pops up where the user can select the individual records. For more information, refer to the Reset Status for All Effective Items.

E/C

The Engineering Control that specifies aircraft or component scheduled maintenance intervals. The E/C field is composed of the data entered in the following fields and are separated by hyphens: Control-Sub E/C-Company. For example: A320-40082-TRAX

Note: The naming convention behind E/Cs and T/Cs are driven by the Config Other field via Switch ![]() COMPANYMULTI. It is recommended that users use option 3 for the Config Other field to follow standard naming processes. For more information, refer to COMPANYMULTI via G/L Interface Switches.

COMPANYMULTI. It is recommended that users use option 3 for the Config Other field to follow standard naming processes. For more information, refer to COMPANYMULTI via G/L Interface Switches.

Note: When Switch ![]() CHOMITEC is set to Yes, the user will not be able to included any characters defined in the Config Other field in the E/C name. When set to No, characters defined in the switch will be allowed in the E/C number.

CHOMITEC is set to Yes, the user will not be able to included any characters defined in the Config Other field in the E/C name. When set to No, characters defined in the switch will be allowed in the E/C number.

Control

The Control (A/C, P/N, A/C Type, or ALL) used to auto generate the E/C reference. This field is used for naming purposes only. When the 'ALL' option is selected the E/C Control field will not auto generate the E/C reference. The E/C reference will auto generate from the Sub E/C field.

Sub E/C

The Sub E/C used to auto generate the E/C reference. This is a free text field used for naming purposes only.

Company

The name of the airline company for which the E/C will be utilized. The Company used to auto generate the E/C reference. When this field is populated, only those aircraft with the same G/L Company via the A/C Master, Other 1 tab can be made effective to the E/C. When the 'ALL' option is selected the Company field will not auto generate the E/C reference. The E/C reference will auto generate from the Sub E/C field.

Note: For more information, refer to the Multi Company Functionality. Also, refer to the A/C Control Button.

Category

The category of the E/C (e.g., AD, SB, CHECK). The E/C Category System Transaction Code is set up via Settings/ Explorer/ System Transaction Code/ Engineering. E/C Authorization Steps and System Notifications can also be set-up within the E/C Category. The category can be used for searching and reporting data in prints. For more information, refer to the E/C Category via the Engineering Transaction Codes Manual.

Sub Category

A Sub Category can be used to further define the E/C Category, if applicable. For example, users may want to classify their ADs for Engines, APUs, and Landing Gear separately. The Sub Category System Transaction Code is set up via Settings/ Explorer/ System Transaction Code/ Engineering.

Classification

The classification of the E/C (i.e. Mandatory, Optional, etc.). E/C classifications can be made mandatory by selecting the mandatory property checkbox in the E/C Mandatory Classification transaction code (via Settings/ Explorer/ System Transaction Code/ Engineering). If a P/N E/C has a classification where the mandatory property checkbox is selected, the system will force compliance at the next vendor or shop repair order visit and cannot be overridden. A part with a mandatory P/N E/C should only be added to a R/O when compliance is required and the work will be accomplished during that repair visit; these P/N E/Cs will not receive automatic compliance upon receipt of the R/O. E/C classifications with the mandatory property checkbox selected will trigger mandatory flags and alerts throughout the system (i.e. planning query results); and when the E/C or P/N E/C planning element checkboxes are selected in the Planning Query, the E/C Classification field appears in the planning filters. For more information refer to the E/C Mandatory Classification via the Engineering Transaction Code Manual.

E/C Description

The description is the basic title of the E/C. The number of characters is limited in this field and a longer description can be entered in the E/Cs E/C Content Tab.

Revision

The revision number of the E/C. This can be alpha numeric. When the revision is changed and saved, the system will prompt the user with a revision control record, where the changes made for the specific revision can be saved for auditing purposes. The 'Revised By' field will be automatically updated with the user's user code, and the revision date can be set as required.

Note: If Switch ![]() ECAUTH is set to Yes, authorization will be required for all E/Cs that have been revised.

ECAUTH is set to Yes, authorization will be required for all E/Cs that have been revised.

Revised By

The user who creates and/or authorizes the E/C revision.

Date (Revision Date)

The date the E/C was put into revision (if E/C is currently in revision), or the date the final authorization step was completed in the E/C revision authorization process.

Amendment

The amendment field normally relates to AD amendment numbers. This is alpha numeric and issued by the authority or company issuing the P/N E/C.

Issued By

The vendor or authority (i.e. FAA, JAA Task Card.) who issued the E/C.

Issued Date

The date the E/C was issued by the vendor or authority.

Chapter / Section / Paragraph

The ATA chapter/section/paragraph, as applicable. For more information, refer to the ATA Specifications via the Settings Training Manual.

Note: System Notifications can be sent to select users whenever a new P/N Serial Number is received into Inventory that is associated to an Engineering Control with the specified ATA Chapter(s). The notifications are sent once the E/C for the P/N is accepted via the P/N E/C Selection window at Order Receiving, Receiving Inspection, or P/N Initial Load (see Receiving Switch ![]() ENGCOMP for more information). This System Notification is called 'RECEIVED PART WITH EFFECTIVE EO.' For more information refer to the System Notification window of the Settings Training Manual.

ENGCOMP for more information). This System Notification is called 'RECEIVED PART WITH EFFECTIVE EO.' For more information refer to the System Notification window of the Settings Training Manual.

New ATA Chapter, Section, Paragraph ![]() button

button

Select to add multiple ATA references to the Engineering Control. Each time this button is selected a new set of chapter/section/paragraph fields become available.

Delete ATA Chapter, Section, Paragraph ![]() button

button

Select to delete any of the selected ATA references for the Engineering Control. Each time this button is selected, the selected set of chapter/section/paragraph fields are deleted.

Note: At least one set of ATA chapter/section/paragraph must exist; if there is only one reference remaining, it cannot be deleted.

_____________________________________________________________________________________

Share

Share

Print

Print