Share

Share

Print

Print

For regular Engineering Controls, the Schedule tab allows users to create or edit the E/C's schedule details. But from the E/C Shop window, the Schedule tab is available to edit certain features of the Shop E/C.

The only changes that can be made to the Shop E/C schedule is the Next E/C functionality, the Effective Date, and the Repeat Number (see below). The First and Repeat Schedules are not meant to be utilized by Shop E/Cs; these fields are only meant for regular E/Cs.

![]() Note: As of version 5 and later releases, the Schedule tab is no longer available.

Note: As of version 5 and later releases, the Schedule tab is no longer available.

The following information/options are available in this window:

_____________________________________________________________________________________

Effective Date

Entered as the date from which the user requires to track time on the E/C being set up unless a Total Schedule has been defined. Once the effective date is entered and the A/C or P/N Effectivity for the E/C is applied, changing the effective date on this Tab will not change the effective dates on each individual aircraft or component that the E/C is effective to. Either the Effectivity will need to be removed and re-applied, or the effective date field will need to be changed individually in the Effectivity Override window for each tail number or component.

Note: If the effective date is greater than the current date, planning will not forecast for this E/C until the effective date has been met.

Reset Date for all Effective Items ![]() button

button

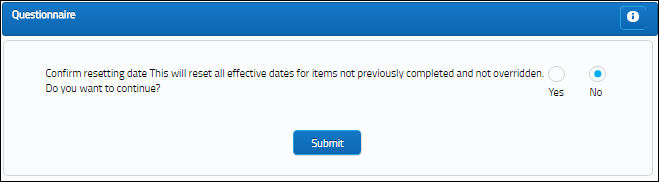

Select the Reset Date button to reset the effective dates for items not previously complied with and/or not overridden. The following window will appear upon resetting the effective dates:

Repeat Number

The number of occasions the E/C will be repeated. If the Repeat Number is set to 1, the E/C is a one time only E/C and only the First Schedule is applicable. If the Repeat Number is set to 9999, the E/C will be carried out on the First Schedule 1 time and then the Repeat Schedule indefinitely. If the Repeat Number is a specific number, such as 5, the E/C will be carried out on the First Schedule 1 time and then be repeated 4 times according to the parameters configured on the Repeat Schedule (and then terminated).

Note: If the Repeat Number is set to 1, the Redo checkbox appears:

Next E/C

Used to set up a dependency between a group of E/Cs that will follow each other at the time of compliance. For example, if an A-Check has four phases (A1, A2, A3, A4) with each phase having its own requirements, each phases can be set up independently and then associated to the next E/C in sequential order. For the functionality to work the first E/C (A1) requires its effective date to be set and then each of the subsequent E/Cs (A2, A3, A4) must have their effective date set to null. The E/Cs repeat number should be set to 9999 so the cycle continues.

Once the initial E/C (A1) is complied with, the system will automatically change the next E/C’s (A2) effective date to the initial E/C’s (A1) compliance date. For example, E/C A1 has been set up with an effective date of 11/21/2017, and E/C A2, A3, and A4 have be set up with an effective date set to null. At the time of A1’s compliance – which, in this example is 04/28/2018 – A2’s effective date automatically changes to 04/28/2018 while A1’s effective date reverts to null; A2 is now the next E/C due and will show in a Planning Query.

The Select Next E/C Query ![]() button will display the next E/C subsequent to the current E/C being viewed.

button will display the next E/C subsequent to the current E/C being viewed.

Note: The Schedule Control Tab is a preferred method of creating E/C relationships and dependencies.

Note: It is important to select the the current phase of the Next E/C when deferring a defect. For additional information, refer to How to Query for the Current Phase of the Next E/C via Troubleshooting Tips of the Engineering - E/C Training Manual.

_____________________________________________________________________________________

Share

Share

Print

Print