Share

Share

Print

Print

The Auto R/I, or Auto Re-Inspect ![]() button allows the user to copy the information of a Defect Report to a new Defect Item, but with the capability of updating the Defer To Schedule and Defer Notes. This button is different from the New Item

button allows the user to copy the information of a Defect Report to a new Defect Item, but with the capability of updating the Defer To Schedule and Defer Notes. This button is different from the New Item ![]() button in that it carries over information from the Defect Report Detail, Defer tab in addition to the general information. For more information, refer to the New Item

button in that it carries over information from the Defect Report Detail, Defer tab in addition to the general information. For more information, refer to the New Item ![]() button.

button.

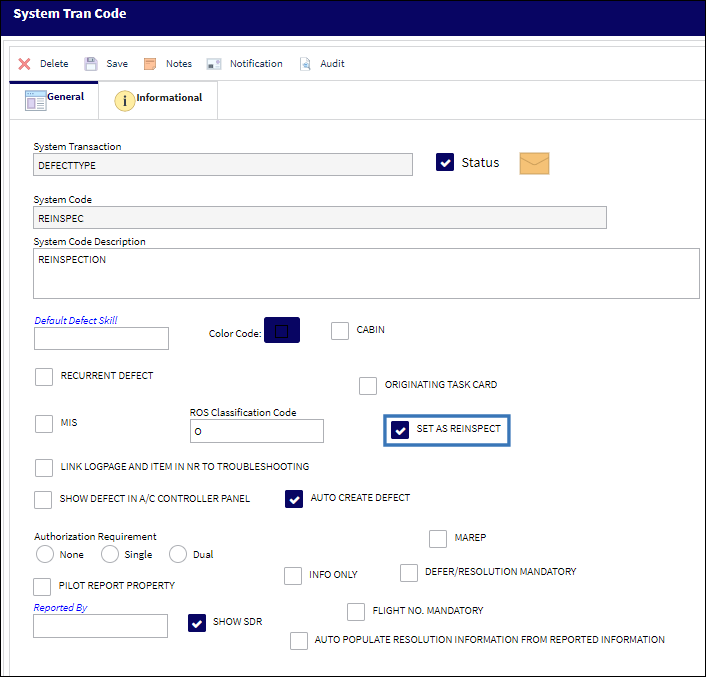

The Defect Type that is created in the new Defect Report via the Auto R/I ![]() button can be defaulted via the Set as ReInspect checkbox, via the Defect Type Transaction Code. For additional information, refer to the Defect Type Transaction Code via the Technical records Transaction Code manual.

button can be defaulted via the Set as ReInspect checkbox, via the Defect Type Transaction Code. For additional information, refer to the Defect Type Transaction Code via the Technical records Transaction Code manual.

![]() This button is security controlled via Technical Records/Update/Defect Report/Defect - Auto Re-inspect. For more information refer to the Security Explorer via the System Administration Training Manual.

This button is security controlled via Technical Records/Update/Defect Report/Defect - Auto Re-inspect. For more information refer to the Security Explorer via the System Administration Training Manual.

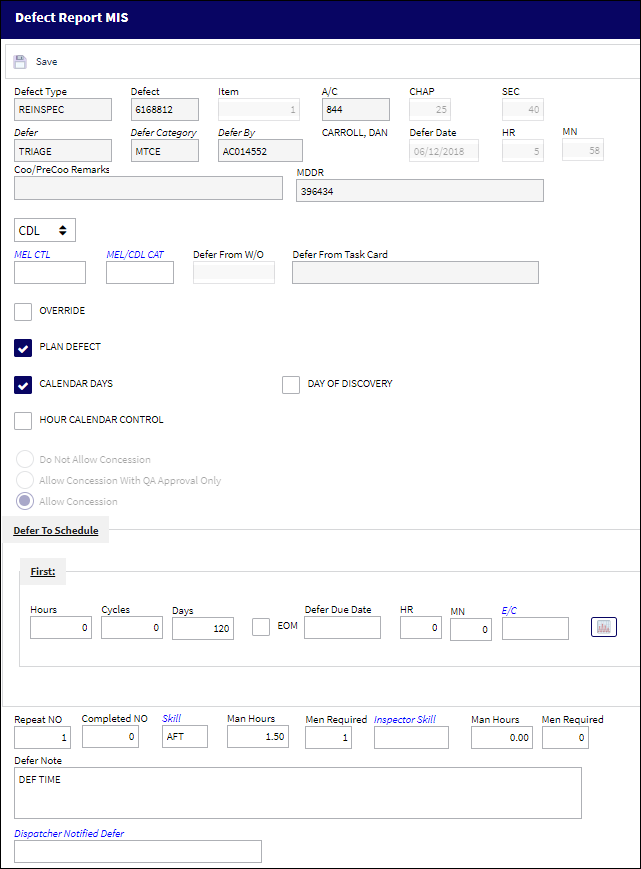

Selecting the Auto R/I ![]() button opens the Defect Report MIS window:

button opens the Defect Report MIS window:

The Defect Type and Number, A/C, Chapter, and Section will carry over from the Defect Report Detail, General tab, and the Defect Item will be sequential to the prior Defect Report. The Defer information will carry over from the Defect Report Detail, Defer tab. The Defer To Schedule will be available to update.

The following information/options are available in this window:

_____________________________________________________________________________________

Defer To Schedule Hours

The number of flight hours/cycles/days in which the deferment must be resolved from the beginning of the Report or Defer Date based on system configuration.

Note: The Defer To Schedule Hours field works with Calendar Hours and the Defer To Schedule Days works with the Calendar Days checkbox.

Defer Due Date

The date and time the deferment must be resolved by.

Defer To Schedule Time

The scheduled time that the deferment must be resolved by.

Defer To Schedule E/C

The E/C which the Deferred Defect will follow for a schedule. When this E/C is placed on a Work Order, a Non-Routine Task Card will be created for the associated Deferred Defect.

EOM checkbox

When selected, the scheduled Due Date for the Defer is in the End of the Month. For example, if the scheduled Due Date 9/22/2016, with the EOM checkbox selected, the Due Date becomes 9/30/2016. When the EOM checkbox is selected, a red EOM icon appears under the Due Date.

![]() This checkbox is security controlled via the Security Explorer/ Technical Records/ Update/ Defect Report/ /Defect Report Defer OEM Checkbox. For additional information, refer the the Security Explorer via the System Administration Training Manual.

This checkbox is security controlled via the Security Explorer/ Technical Records/ Update/ Defect Report/ /Defect Report Defer OEM Checkbox. For additional information, refer the the Security Explorer via the System Administration Training Manual.

Planning ![]() button

button

Select the Planning ![]() button to received the E/C Category Selection window. Select the E/C Category to narrow the planning query to a specific E/C Category or exit the Drop Down Selection window to view all A/C E/C coming due. The Planning/SDI window will appear. Select E/C of the selected category in which the Deferred Defect will follow on to the Work Order and populate the E/C field.

button to received the E/C Category Selection window. Select the E/C Category to narrow the planning query to a specific E/C Category or exit the Drop Down Selection window to view all A/C E/C coming due. The Planning/SDI window will appear. Select E/C of the selected category in which the Deferred Defect will follow on to the Work Order and populate the E/C field.

Note: Only Scheduled E/Cs will result in the Planning/SDI window.

Override checkbox

Selecting this checkbox will open the MDDR field and will allow the user to enter the MDDR number for those deferred defects which do not have an MDDR automatically generated. This checkbox can be used to allow the user to enter an MDDR number from a previous defect report on another defect report allowing for the resolution of both Defects Reports (Aircraft Log Page). Default setting of the Override checkbox is dependant on the MDDRAUTO configuration.

MDDRAUTO - (MDDR Auto Number Creation, Next Sequence Number) - When set to Yes, the system will automatically assign the next sequential number to MDDRs in Defect Reports (Defer Tab). The Config Number field is used.

MDDRAUTO - (MDDR Auto Number Creation, Next Sequence Number) - When set to Yes, the system will automatically assign the next sequential number to MDDRs in Defect Reports (Defer Tab). The Config Number field is used.

Plan Defect checkbox

Select this checkbox to include this record in the A/C Planning Query. This checkbox is selected by default. If de-selected, the Defer Defect will not appear in the A/C Planning Query.

![]() This checkbox is security controlled via Technical Records/ Update/ Defect Report/Defect Report Defer Plan Defect. For more information refer to the Security Explorer via the System Administration Training Manual.

This checkbox is security controlled via Technical Records/ Update/ Defect Report/Defect Report Defer Plan Defect. For more information refer to the Security Explorer via the System Administration Training Manual.

Calendar Days checkbox

If a deferment is limited by a number of days (the Days field is populated), selecting this checkbox would indicate that the limit is by calendar days rather than by flight days. This checkbox is selected by default. If a deferment is limited by a number of flight days (Days field) then this checkbox should not be selected. This checkbox is selected by default. Therefore, if de-selected, only days in which the aircraft flew would be counted against the defect's actual time.

Note: The MEL Master may contain the Calendar Days checkbox status which may be overridden against the Defect.

Hour Calendar Control checkbox

Select this checkbox to control the calendar by hour.

Note: The hours populated in this field are not Calendar Hours, rather flight hours from the effective date or last compliance.

Day of Discovery checkbox

The Day of Discovery checkbox helps determine the Due Date from when the Defect is established. When selected, it will have the same date as produced from calendar days, but will be listed in black indicating that it is not overdue throughout the final day to give the user until the end of the day (23:59) before it is overdue. When deselected, the Due Date will have the same date as produced from calendar days, but will be listed on black or red, thus indicating whether or not it is overdue, depending on the time of day the Defect was deferred.

Note: The MEL Master may contain the Day of Discovery checkbox status which may be overridden against the Defect.

Repeat No.

The number of times that a Deferred Defect is to be performed in order to reach closed status. The repeat field is used for defining watch items or repeat inspections. This field works with the Completed field. When this field is greater than '1' the Repeat Schedule fields appear. The Complete Number will only increment when the Non-Routine Task Card associated to the defect is closed. It will not increment if the Non-Routine Task Card is closed with the 'Ongoing trouble shooting checkbox' flagged against the closing action. For additional information regarding the Ongoing Trouble Shooting field, refer to the Task Card Work Button via the Production Training Manual. Once a Repeat Number has been established, it must be complied with. The Repeat Number can be complied with via the Defect Report Detail, Resolution Tab, or by entering troubleshooting items in the Defect Report Detail, Troubleshooting tab. For information on how to comply with a Repeat Number, go to Defect Report Detail, Resolution Tab and Complying with Repeat Number via Troubleshooting Items.

Note: System Standard applies. Repeat '9999' means infinite as long as the aircraft is owned/leased by the company.

Completed No.

The number of times that a Deferred Defect was performed in order to reach closed status. The Completed field must match the Repeat field in order to close the Deferred Defect. To use the Troubleshooting Tab directly on the Deferred Defect to increment the Completed Number, the user must flag the Troubleshooting checkbox on the Resolution Tab. The proper system configuration must be defined in order to use the Troubleshooting tab. This tab will track all of the Completed records as the Deferred Defect is added to the Work Order Non-Routine Task Card.

TCDFTOPN - (Leave Defect Open When Closing Task Cards Attached To It) - When set to Yes, the system will have Defect discrepancies remain in 'Open' status when the attached Task Cards are closed.

TCDFTOPN - (Leave Defect Open When Closing Task Cards Attached To It) - When set to Yes, the system will have Defect discrepancies remain in 'Open' status when the attached Task Cards are closed.

Skill

Enter the mechanical skill required to close the Deferred Defect.

MDSKMNHR - (Make Skill, Man Hours and Man Require fields mandatory in Defect Report, Defer tab.) - When set to Yes, when creating a Defect Report, the user cannot save the report unless the Skill, Man Hours and Men Required fields are all populated. If the switch is set to No, the Skill, Man Hours, and Men Required fields are not mandatory.

MDSKMNHR - (Make Skill, Man Hours and Man Require fields mandatory in Defect Report, Defer tab.) - When set to Yes, when creating a Defect Report, the user cannot save the report unless the Skill, Man Hours and Men Required fields are all populated. If the switch is set to No, the Skill, Man Hours, and Men Required fields are not mandatory.Note: This field will be mandatory if the E/C field is populated regardless of the above mentioned switch's configuration.

Man Hours - The total number of hours (per person) required to close the Deferred Defect.

Men Required - The total number of people required to close the Deferred Defect.

Inspector Skill

Enter the Inspector Skill required to close the Deferred Defect.

Man Hours - The total number of hours (per person) required to close the Deferred Defect.

REQINSMAN - When set to Yes, the Man Hours field will auto populate when the Inspector field is populated. When set to No, the Man Hours field will not auto populate when the Inspector Skill field is populated.

REQINSMAN - When set to Yes, the Man Hours field will auto populate when the Inspector field is populated. When set to No, the Man Hours field will not auto populate when the Inspector Skill field is populated.Men Required - The total number of people required to close the Deferred Defect.

Due At A/C Hours / Cycles / Due Date

The Aircraft Hours/Cycles that the item is due at and the calculated due date of the item (rounded to the nearest date). This information also appears in the A/C Planning Query Detail View.

Do Not Allow Concession radio button

Select this option so Concessions cannot be applied against a Deferred Defect.

Note: This checkbox is de-selected by default.

Allow Concession with QA Approval Only

Select this radio button to allow Concessions to be applied against this Deferred Defect ONLY with QA approval.

Allow Concession

Select this radio button to allow Concessions to be applied against this Deferred Defect.

Capability Area

The Capability Area identifies where a maintenance task can be accomplished in association with the customer's internal capabilities (e.g., a particular E/C can only be accomplished during a heavy maintenance visit at a heavy maintenance capable Site). The Capability Area can be assigned for E/Cs, P/N Controls, and Defect Reports. However, a maintenance task with any Capability Area can be scheduled on Work Orders at Sites that have their Capability Area set to 'ALL'.

Planning Department

The Planning Department Code to assist the Planning department in filtering and planning tasks.

Note: When Switch ![]() PLANDEPT is set to Yes, the Planning Dept and Planning Sub Dept fields become mandatory in the following windows: P/N Control, Engineering Control/ Other tab, Defect Report/ Defer tab. When set to No, the Planning Dept and Planning Sub Dept fields are not mandatory. For more information, refer to Switch

PLANDEPT is set to Yes, the Planning Dept and Planning Sub Dept fields become mandatory in the following windows: P/N Control, Engineering Control/ Other tab, Defect Report/ Defer tab. When set to No, the Planning Dept and Planning Sub Dept fields are not mandatory. For more information, refer to Switch ![]() PLANDEPT via the Planning Switches Training Manual.

PLANDEPT via the Planning Switches Training Manual.

Defer Note

Defect defer note phrases that may be used to describe deferment requirement(s). For additional information, refer to the Defect Defer Notes Phrase Transaction Code via the Technical Records Transaction Code manual.

Dispatch Notified Defer

The dispatcher notified of the deferment. When the Dispatch Concurrence checkbox is selected in the MEL Master, General tab, and a Defect is deferred by the specified MEL/CDL or GMM, the Dispatch Notified Defer field in the Defect Report Detail, Defer tab will be mandatory.

DSPNTFR - (Dispatcher Notified field to be Mandatory on the Resolution tab or the Defer tab) - If set to Yes, the Dispatcher Notified field will be mandatory on the Resolution tab or the Defer tab of the Defect Report.

DSPNTFR - (Dispatcher Notified field to be Mandatory on the Resolution tab or the Defer tab) - If set to Yes, the Dispatcher Notified field will be mandatory on the Resolution tab or the Defer tab of the Defect Report.

_____________________________________________________________________________________

Additional Functionality:

The Defect Type of the Defect Report MIS created from the Auto R/I ![]() will default to that which is selected to be Set as ReInspect for a particular Defect Type System Transaction Code.

will default to that which is selected to be Set as ReInspect for a particular Defect Type System Transaction Code.

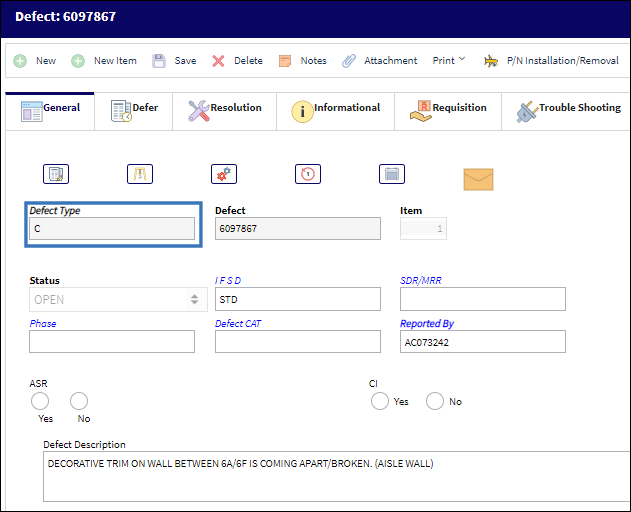

The following Defect Report has been created. Notice its Defect Type.

From the System Transaction Codes, a different Defect Type has been designated to be Set as ReInspect.

Notice the Defect Type distinguished as Set as ReInspect is defaulted to the Defect Report MIS created from the Auto R/I ![]() button.

button.

For more information, refer to the Defect Type System Transaction Code.

If no Defect Type System Transaction Code is designated to be Set as ReInspect, the Defect Type of the Defect Report MIS created from the Auto R/I ![]() button will default to that of the initial Defect Report.

button will default to that of the initial Defect Report.

Share

Share

Print

Print