Share

Share

Print

Print

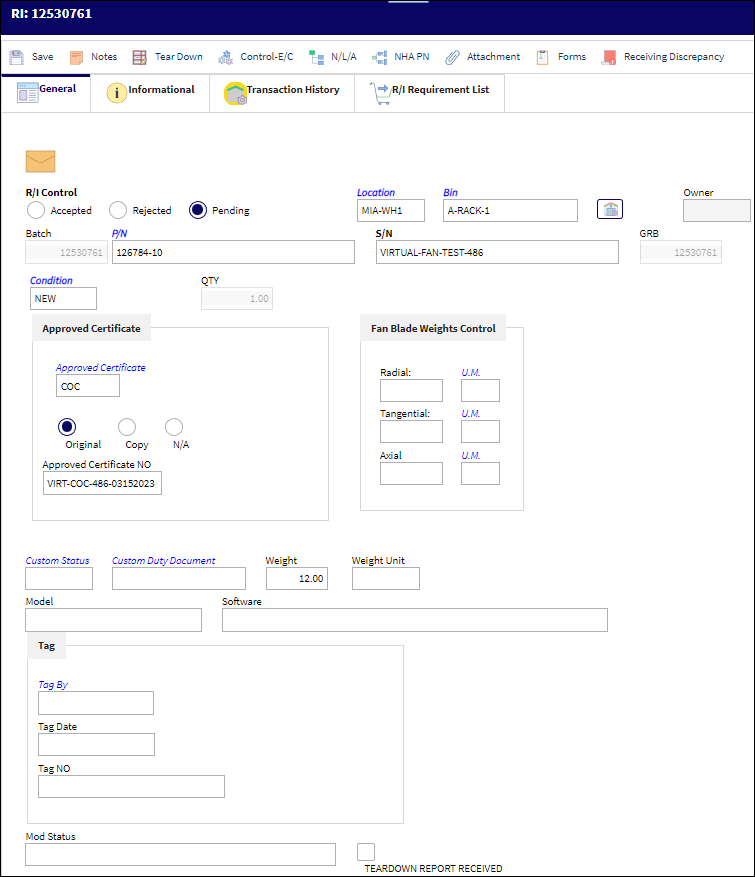

The Receiving Inspection General tab is used to complete the receiving inspection of the part and accept or reject it into the system.

Note: Many fields in this window are informational.

The following information/options are available in this window:

_____________________________________________________________________________________

R/I Control

Receiving Inspection Control. The user must select either the Accepted or Rejected radio button during this process. But before the item is accepted, the user must first select the Pending radio button. While the R/I is in Pending status, the linked P/N Controls and P/N E/Cs can be reviewed through the Control-E/C button. Once the controls are reviewed and saved, then the Accept radio button should be selected and saved. If the item is rejected, then the Rejected radio button must be selected and the part placed in a quarantine location/bin and given a U/S (Unserviceable) code.

![]() Note: The Pending radio button has been added to the Receiving Inspection window. This status option allows users to review/edit the P/N Controls and P/N E/Cs of the part without updating the Control tables. The tables will not be formally updated until the R/I status is changed to Accepted and saved. For more information refer to R/I Pending Status and Updating Controls.

Note: The Pending radio button has been added to the Receiving Inspection window. This status option allows users to review/edit the P/N Controls and P/N E/Cs of the part without updating the Control tables. The tables will not be formally updated until the R/I status is changed to Accepted and saved. For more information refer to R/I Pending Status and Updating Controls.

Location

The Location for maintenance events, inventory stores, orders, transactions, or training events.

Bin

The specific storage bin within the inventory location.

Owner

The name of the owner of the part, when applicable.

Batch

The inventory number that is currently associated with a part or group of parts. A part's Batch number can change after various types of transactions take place.

P/N

The Part Number reference for the aircraft part. This may be changed to another part number, if required. A warning will be issued if this happens.

![]() This field can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Receiving Inspection Disable P/N Field. For more information refer to the Security Explorer via the System Administration Training Manual.

This field can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Receiving Inspection Disable P/N Field. For more information refer to the Security Explorer via the System Administration Training Manual.

![]() This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

S/N

The Serial Number for the specific serialized part.

![]() This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

Goods Rcvd Batch (GRB)

The original inventory number assigned to the part or group of parts when initially introduced/received into inventory. This number will remain the same for a part even if/when the part's Batch number changes.

Condition

The condition of the part.

![]() This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

U/S Code

Unserviceable Code that applies to the part, to be stored in a quarantine location.

QTY

The quantity of parts that were received.

Vendor Lot

Vendor batch number of the part entered upon receiving or initial load, as applicable. This field can contain up to 20 characters.

![]() This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

Tool Life Expiration

The tool life expiration date of the part, as applicable.

![]() This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

Shelf Life Expiration

The shelf life expiration date of the part, as applicable.

Note: This field only appears if the part contain shelf life configurations via the P/N Master, Inventory tab.

Approved Certificate

The type of certificate approving the part (ie. Form 1, EASA etc.). The user may choose from a pre-defined transaction code, or enter the Approval Certificate manually.

RIAPCRMN - (Approved Certificate (field) Mandatory). If set to Yes, the Approved Certificate field will be mandatory in the Receiving Inspection window. If set to No, the Approved Certificate field will not be mandatory in the Receiving Inspection window.

RIAPCRMN - (Approved Certificate (field) Mandatory). If set to Yes, the Approved Certificate field will be mandatory in the Receiving Inspection window. If set to No, the Approved Certificate field will not be mandatory in the Receiving Inspection window.

Original radio button - Select this radio button to indicate that the certificate is an original.

Copy radio button - Select this radio button to indicate that the certificate is a copy.

N/A radio button - Select this radio button to indicate that the certificate is not available.

![]() This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

Approved Certificate Number

The Approved Certificate Number. This is a free text field.

![]() Note: This field can hold up to 30 characters.

Note: This field can hold up to 30 characters.

Fan Blade Weights Control ![]()

Radial - The radial weight, and its accompanying unit of measurement, of the received fan blade.

Note: When the Radial Weight Control at Batch Level checkbox is selected, the Radial Weight Control field becomes mandatory in the Receiving Inspection window and must be populated before saving. Refer to the P/N Master, Optional tab.

U.M. - The unit of measurement.

Tangential - The tangential weight, and its accompanying unit of measurement, of the received fan blade.

Note: When the Tangential Weight Control at Batch Level checkbox is selected, the Tangential Weight Control field becomes mandatory in the Receiving Inspection window and must be populated before saving. Refer to the P/N Master, Optional tab.

U.M. - The unit of measurement.

Axial - The axial weight, and its accompanying unit of measurement, of the received fan blade.

Note: When the Axial Weight Control at Batch Level checkbox is selected, the Axial Weight Control field becomes mandatory in the Receiving Inspection window and must be populated before saving. Refer to the P/N Master, Optional tab.

U.M. - The unit of measurement.

Custom Status

Customs status that applies to the part in the transaction, as applicable.

Custom Duty Document

Document used to verify that the part was accepted by customs.

![]() Note: This field supports up to 20 characters.

Note: This field supports up to 20 characters.

Tool Calibration Number

This is a unique number used to define a tool. This field only appears if the Tool Calibration Number Required checkbox is selected via the P/N Master, Inventory tab, via the P/N Master of the Settings Training Manual.

![]() Note: This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch

Note: This field, along with others in the window, can be disabled (grayed out) through the Security Explorer via Receiving/ Update/ Receiving Inspection/ Tool Calibration Control with Switch ![]() TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

TOOLCALCONTROL set to Yes. For more information, refer to the Security Explorer via the System Administration Training Manual.

Weight

The weight of the component being received. This information is being pulled from the Optional Tab of the P/N Master.

Note: This field will appear based on the configuration of the "Weight Control at Batch Level" checkbox.

Tag By

Vendor Tag By information.

Tag Date

Date of the Tag.

Tag Number

The tag number associated with the part.

Model

The manufacture modification number. This field is only informational.

Software

The software used by the component being received.

Note: NLA parts with software information entered in this field will behave like software components in the system, particularly as it relates to its relationships with NHAs. Further, the NLA part will contain the software icon indicating it is a software component.

Mod Status

The manufacture modification status. This field is informational only.

Note: This field is mandatory when the Mod Status checkbox is selected in the P/N Master, Technical Engineering Tab via the P/N Master of the Settings Training Manual.

Tear Down Report Received checkbox

If a Tear Down report has been received with the item. If checked, the system will send notification to all users who are set up in the System Notification/Tear Down Notification program.

Label Copies

The number of label copies to be created.

Times Accrual Hours/Cycles/Days

Total time accrued against a serialized part.

Birth Date![]()

The Birth Date of the part. This date is auto populated with the date specified in Purchase Order Receiving, Times Accrual tab. The 'Birth Date' field is used to calculate the Calendar Days of a part number. If the Birthdate field is not populated, the system will default to using the Order Receiving date to calculate the Calendar Days. This field only appears if Switch ![]() PNBIRTHDAY is set to Yes. For additional information, refer to Switch

PNBIRTHDAY is set to Yes. For additional information, refer to Switch ![]() PNBIRTHDAY via the Receiving Switches Manual.

PNBIRTHDAY via the Receiving Switches Manual.

Note: This field is only present in eMRO v5.

_____________________________________________________________________________________

The Export as Excel ![]() button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

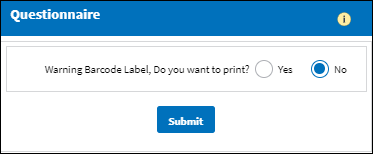

The system will prompt the user to print the tag.

After the receiving inspection transaction is performed and accepted, the item is available for issue to an aircraft.

Once parts have been received and any necessary receiving inspections have been performed, the system can now await entry of the invoice (received from the vendor who sold the parts). Received invoices can be entered via the Link module.

Note: See the Link chapter of this course for additional information regarding entering received invoices into the system.

When accepting a Receiving Inspection for a Repair Order, if any P/N Controls or P/N E/Cs are overdue, the following warning will appear. The message indicates that the part must be sent to repair and will be come unserviceable.

Note: From the Control-E/C ![]() button, the Controls that are past schedule will read 'OVERDUE' in red. To see what this indicator looks like, refer to the Control - E/C Button, via Receiving Inspection Detail.

button, the Controls that are past schedule will read 'OVERDUE' in red. To see what this indicator looks like, refer to the Control - E/C Button, via Receiving Inspection Detail.

Connect P/N to Existing History and Compliance Records:

When Inventory Switch ![]() CNCTPNHST is set to Yes, when a Part Number Serial Number is Accepted and saved in the Receiving Inspection window, a prompt appears asking if the user would like to connect this part to the existing history and compliance records for the same P/N S/N (if available). Users can also choose to not apply existing history records to the P/N S/N depending on their security clearance.

CNCTPNHST is set to Yes, when a Part Number Serial Number is Accepted and saved in the Receiving Inspection window, a prompt appears asking if the user would like to connect this part to the existing history and compliance records for the same P/N S/N (if available). Users can also choose to not apply existing history records to the P/N S/N depending on their security clearance.

Note: Security must be given to specific users in order to receive the message prompt in Receiving Inspection. The security options also allow administration to make the message prompt Yes/No optional or only informational. The securities can be found in the Security Explorer via Receiving/Update/Receiving Inspection/ PN / SN History Connection Yes Button Only and PN / SN History Connection Yes and No Button.

For detailed information refer to Switch ![]() CNCTPNHST via the Inventory Switches Manual.

CNCTPNHST via the Inventory Switches Manual.

Receiving In Use:

The system does not allow two users to be in the same Receiving Inspection at the same time.

Select into the following record.

Select into the same record with a different User.

When second User attempts to select into the same record, a warning message appears.

Share

Share

Print

Print