Share

Share

Print

Print

Receiving Inspection

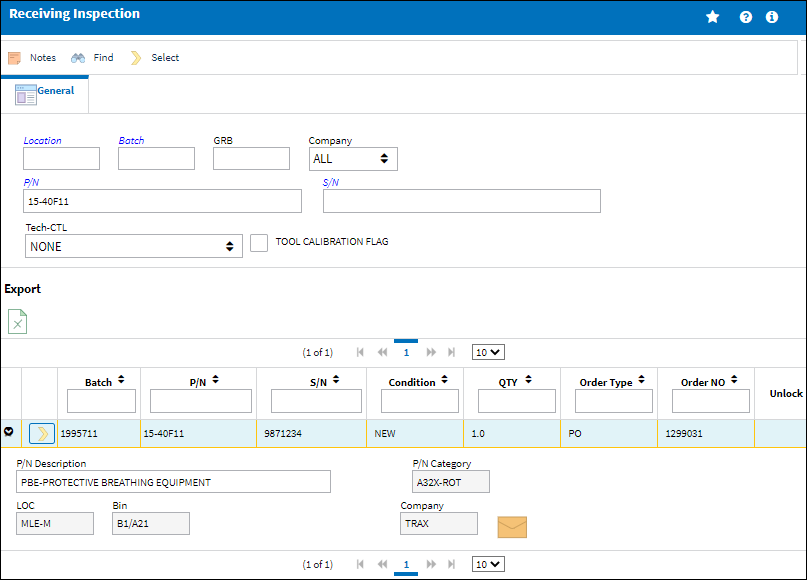

After a part has been ordered and received into the system (via the Order Receiving window) it may require receiving inspection. Receiving Inspection allows for a final review and inspection of the part and its documentation before making it serviceable in inventory; this step is typically performed by a receiving inspector. Receiving inspection is performed according to company practice.

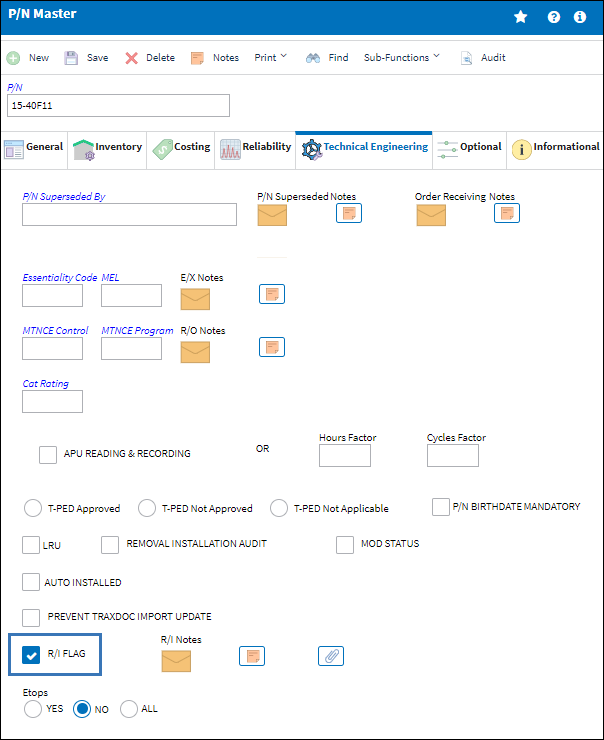

Part Numbers are flagged as requiring receiving inspection in the P/N Master record, via Settings/ Update/ P/N/ Technical Engineering Tab/ R/I checkbox.

;

;

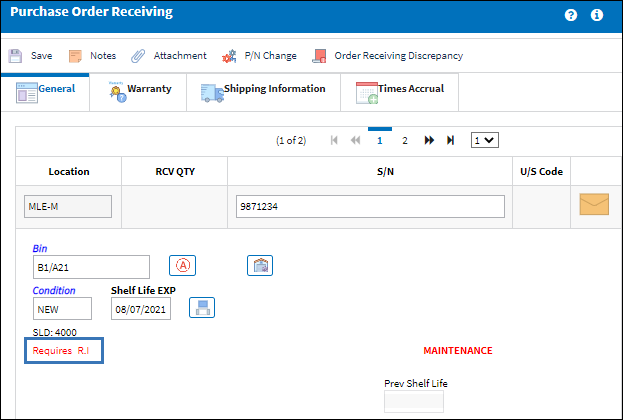

During Order Receiving, parts requiring receiving inspection are flagged with 'Requires R.I.' in red text.

Once the order is received, the part can be found in the Receiving Inspection window. The receiving inspection must either be accepted or rejected from the Receiving Inspection Detail, General Tab.

The following tabs and buttons are available at the initial level.

Receiving Inspection Tabs |

Receiving Inspection Buttons |

|

|

For information on the options in the detail level, refer to Receiving Inspection Detail.

Share

Share

Print

Print