Share

Share

Print

Print

The Schedule Control By tab and Schedule Control tab are used to set up parent/child relationships between E/Cs. Compliance against the parent E/C triggers transactions against the child E/C, and the child E/C follows and reacts to the transactions that occur against the parent E/C; the child E/C must be effective to the aircraft or part that the parent E/C is complied with. The child E/C can also be track independently from its parent E/C.

For example, the Called On control is used to set up a parent/child relationship between 2 E/Cs. When the parent E/C is added to a work order, and the child E/C is effective to the same aircraft, the child E/C is automatically called on and added to the same work order. When the work order is completed and compliance is written, both the parent E/C and the child E/C receive a compliance record. This system behaves in the same manner when a manual compliance is performed against the parent E/C.

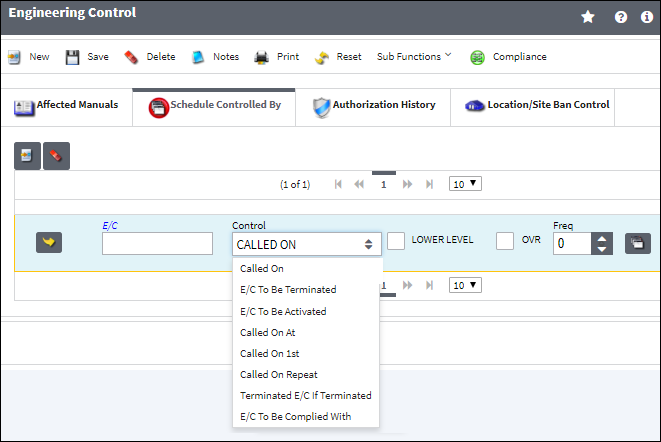

Each control can be used to build different types of parent/child relationships between 2 E/Cs. When the New ![]() button is selected and the control chosen from the drop down menu, the applicable fields appear for that control. The New

button is selected and the control chosen from the drop down menu, the applicable fields appear for that control. The New ![]() button can be selected to create multiple relationships under the same E/C. Records can be removed by selecting the Delete

button can be selected to create multiple relationships under the same E/C. Records can be removed by selecting the Delete ![]() button.

button.

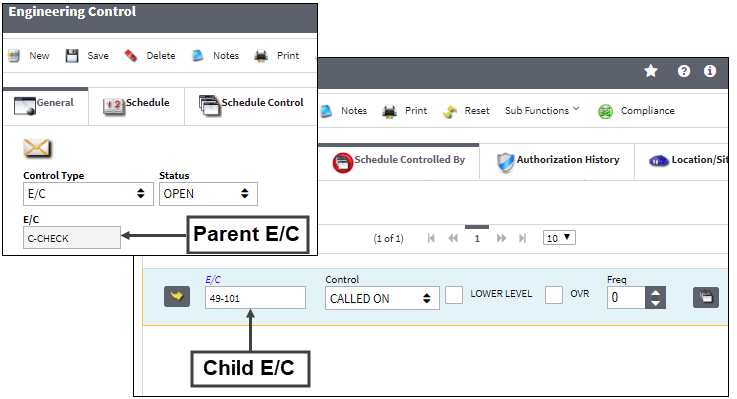

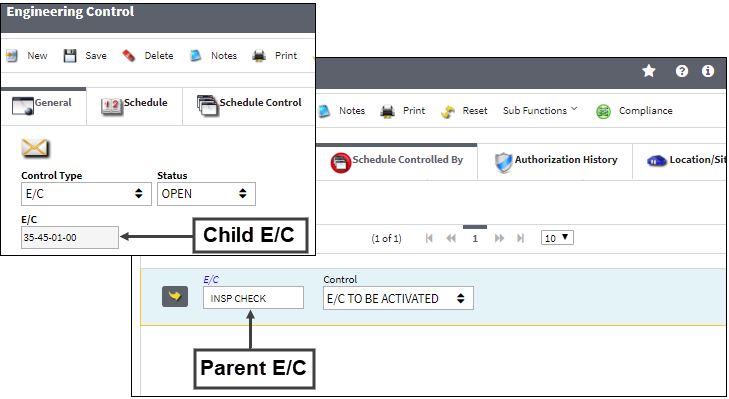

It is important to understand how the Schedule Control and Schedule Control By tabs work based on the control selected. The control and tab used to create the relationship determines if the E/C entered will be the parent E/C or the child E/C to the currently selected E/C.

![]() Note: Child E/Cs can be called onto more than one work order.

Note: Child E/Cs can be called onto more than one work order.

![]() Security must be enabled for the user to view the New

Security must be enabled for the user to view the New ![]() button and the Delete

button and the Delete ![]() button in the Engineering Control window.

button in the Engineering Control window.

The following information/options are available in this window:

_____________________________________________________________________________________

Control

Under the Schedule Control By tab, when the following controls are used the E/C entered will behave as a child E/C to the currently selected E/C:

Called On - The Called On control allows users to specify at which parent E/C frequency a child E/C is to be called on and complied with. The Called On control works in conjunction with the Total Frequency field of the parent E/C's Schedule tab. For additional information, refer to Called On, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

Called On 1st - The Called On 1st and Called On Repeat controls are meant to be used together, where an E/C is activated by one E/C (Called On 1st) and then repeated on another E/C (Called On Repeat). For additional information, refer to Called On 1st, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

Called On At - The Called On At control is used to specify when a child E/C will start a called on relationship to its parent E/C, and at what interval the child E/C will be called on afterwards. For additional information, refer to Called On At, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

Called On Repeat - The Called On Repeat and Called On 1st controls are meant to be used together, where an E/C is activated by one E/C (Called On 1st) and then repeated on another E/C (Called On Repeat). For additional information, refer to Called On Repeat, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

Terminate E/C If Terminated - The Terminate E/C If Terminated control allows users to set up multiple parent/child relationships where multiple parent E/Cs need to be terminated before terminating the child E/C. For additional information, refer to Terminated E/C If Terminated, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

Under the Schedule Control By tab, when the following controls are used the E/C entered will behave as a parent E/C to the currently selected E/C:

E/C To Be Activated - The E/C To Be Activated control is used where upon compliance to the parent E/C the child E/C is activated. For additional information, refer to E/C To Be Activated, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

E/C To Be Complied With - The E/C To Be Complied With control is used so where upon compliance to the parent E/C the child E/C also receives a compliance record. For additional information, refer to E/C To Be Complied With, via Engineering Control, Schedule Control By Tab via the Engineering - E/C Training Manual.

E/C To Be Terminated - The E/C To Be Terminated control is used where upon compliance to the parent E/C the child E/C is terminated. For additional information, refer to E/C To Be Terminated, via Engineering Control Schedule Control By Tab via the Engineering - E/C Training Manual.

Note: When the status of the E/C is Open, or Applicable/ Not Embody, and compliance is manually written, the functionality of termination will still occur.

_____________________________________________________________________________________

Note: When setting up a parent/child E/C relationship it is recommended that the parent and child E/Cs schedules be the same; however, if the schedules must be different then it is recommended that Plan E/C checkbox remains selected for the child E/C. This allows planning to observe the child E/C if the E/C’s schedule is less than the parent E/C - where there is the potential that the child E/C could overfly. For example, if the parent E/C has a schedule of 500 hours and the child E/C’s schedule is 400 hours, if the Plan E/C checkbox is not selected to bring attention to the planners that the child E/C is coming due then it could possibly overfly up to 100 hours. For more information on the Plan E/C checkbox, refer to the Engineering Control, Schedule Tab via the Engineering Training Manual.

Additional Information:

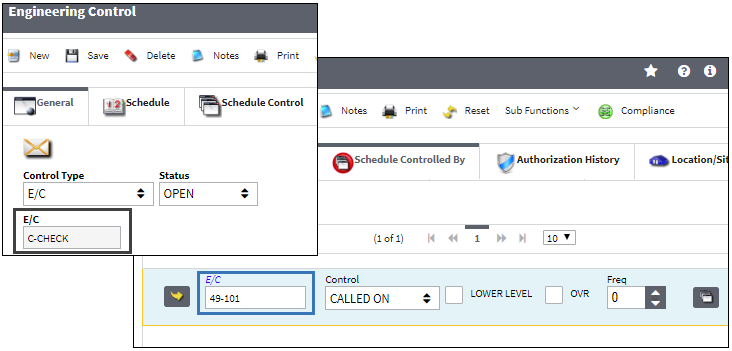

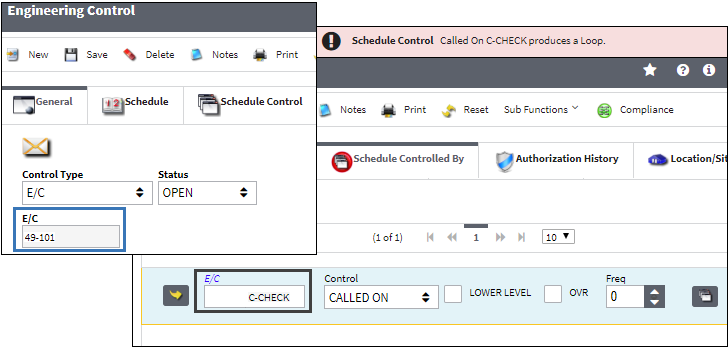

The system will prevent users from creating a loop between 2 E/Cs.

For example, parent E/C 'C-CHECK' calls on child E/C '49-101'.

If the user tries to create a called on relationship where E/C '49-101' is the parent to E/C 'C-CHECK', a hard warning appears.

![]() Note: The Loop hard warning functionality applies to all of the Control types mentioned above with the exception of 'E/C To Be Complied With' and 'E/C To Be Terminated'. These two Control types will not receive a Loop hard warning if a set of E/Cs reference one another using specific these controls.

Note: The Loop hard warning functionality applies to all of the Control types mentioned above with the exception of 'E/C To Be Complied With' and 'E/C To Be Terminated'. These two Control types will not receive a Loop hard warning if a set of E/Cs reference one another using specific these controls.

Share

Share

Print

Print