Share

Share

Print

Print

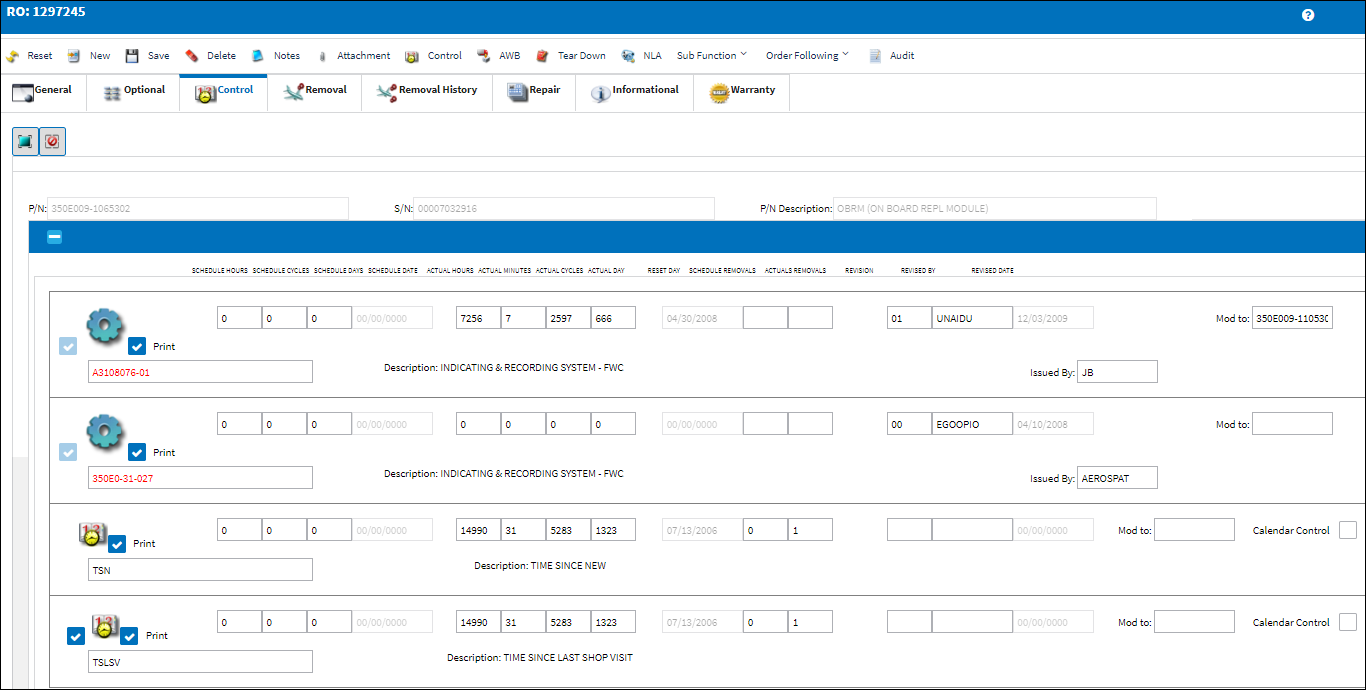

In this tab, part controls and engineering controls may be selected for reset and can be selected to be added to the Repair Order. The items displayed here must be set-up in the relevant sections of the system.

When the items are returned from repair, these controls can be automatically reset and the part number changed (if applicable). The user can select the control to print on the Repair Order if required (for informational purposes).

The fields that appear will depend on the specifications of the controls for the part. See the Settings Training Manual for additional information regarding the setup of Part Controls.

The Part Control information will also appear on the Shop Work Order (R/O Information tab) for viewing.

![]() Note: In eMRO version 5 and later releases the Control button, P/N E/C button, and Repair Order Control tab have been replaced by the Control - E/C button. If a part has been received from an R/O and during R/I the P/N Control or P/N E/C actuals or schedule need to be adjusted, the user will need to make the necessary updates via the P/N Control Authorization or P/N E/C Authorization windows.

Note: In eMRO version 5 and later releases the Control button, P/N E/C button, and Repair Order Control tab have been replaced by the Control - E/C button. If a part has been received from an R/O and during R/I the P/N Control or P/N E/C actuals or schedule need to be adjusted, the user will need to make the necessary updates via the P/N Control Authorization or P/N E/C Authorization windows.

The following information/options are available in this window:

_____________________________________________________________________________________

Expand ![]() button/Collapse

button/Collapse ![]() button

button

Select the Expand ![]() button to expand the P/N line for a tree view of all associated Controls and relevant information. Select the Collapse

button to expand the P/N line for a tree view of all associated Controls and relevant information. Select the Collapse ![]() button to collapse the tree.

button to collapse the tree.

P/N

Part Number associated to the Repair Order. Please note that any additional Part Numbers which may appear on this tab may be NLA to the NHA which appears on the Report Order Detail, General tab. ALL NLA component controls will appear under the appropriate P/N S/N.

S/N

Serial Number associated to the Repair Order. Please note that any additional Serial Numbers which may appear on this tab may be NLA to the NHA which appears on the Report Order Detail, General tab. ALL NLA component controls will appear under the appropriate P/N S/N.

P/N Description

The description of the part.

RO Control checkbox

Select the RO Control checkbox if you require this control to be reset by the Repair Order or if the part is received either at Order Receiving or Receiving Inspection (depending on the following switch):

ROCTLRI - (R/O Reset Control At R/I) - If set to 'Yes', the R/O Control tab will appear via the Receiving Inspection option. If set to 'No', the R/O Control tab will appear via the RO receiving option. The RO Control tab is used to select or de-select the "reset" flag for P/N Controls and E/C's.

ROCTLRI - (R/O Reset Control At R/I) - If set to 'Yes', the R/O Control tab will appear via the Receiving Inspection option. If set to 'No', the R/O Control tab will appear via the RO receiving option. The RO Control tab is used to select or de-select the "reset" flag for P/N Controls and E/C's.

![]() Note: In eMRO version 5 and later releases, Switch ROCTLRI is not in use. The Control tab has been replaced by the Control - E/C button.

Note: In eMRO version 5 and later releases, Switch ROCTLRI is not in use. The Control tab has been replaced by the Control - E/C button.

Note: The Auto Reset checkbox may be defined at the P/N Control Code level, overridden at the P/N level and against the Repair Order. Additionally, P/N Controls may be defined to Do Not Reset at RO. If this is the case, the select checkbox will not appear for selection and therefore may not be overridden at the Repair Order Level. Finally, P/N E/C may be defined at the P/N Effectivity window.

![]() This button is security controlled via Security Explorer/Orders/Update/Repair Order. For more information refer to the Security Explorer via the System Administration Training Manual.

This button is security controlled via Security Explorer/Orders/Update/Repair Order. For more information refer to the Security Explorer via the System Administration Training Manual.

Print checkbox

Select to require the control detail to print on the Repair Order.

Note: This may be pre-defined at both the P/N Control and P/N E/C windows. This may be overridden at the Repair Order level.

ROS Classification Code

The ROS Classification Code is used to specify the ROS message type that will be sent from the system to the Vendor. For additional information, refer to ROS Classification Code, via the Repair Order Detail, Control Tab of the Orders Training Manual.

Control

Any part controls applicable to this part/serial number will appear here. This could be from the Time Control effectivity (TSN, TSO, TSLSV etc.) or from the E/C file (for modifications, AD's etc.). P/N E/Cs are displayed in RED if they are mandatory.

P/N Control ![]() icon - This icon indicates that the control is a P/N Control. The icon is an informational flag only. All P/N Controls are defined as P/N Control Codes in the system transaction codes (via Settings/ Explorer) and attached to the Part Number via the Settings/ Update/ P/N Master, P/N Control button.

icon - This icon indicates that the control is a P/N Control. The icon is an informational flag only. All P/N Controls are defined as P/N Control Codes in the system transaction codes (via Settings/ Explorer) and attached to the Part Number via the Settings/ Update/ P/N Master, P/N Control button.

P/N E/C ![]() icon - This button indicates that the control is a P/N E/C. Users may select this button to view the P/N E/C, as it appears in the Engineering Control window.

icon - This button indicates that the control is a P/N E/C. Users may select this button to view the P/N E/C, as it appears in the Engineering Control window.

Control Description

The description of the Control. This description appear beneath the Control code. The P/N Control descriptions are defined in the code itself via Settings/ Explorer/ System Transaction Code. The P/N E/C descriptions are defined via the Engineering/ Update/ Engineering Control, General tab.

Select All ![]() button

button

Selects all items by placing checks in the checkboxes to the left.

Deselect All ![]() button

button

Deselects all items by removing all checks in the checkboxes to the left.

Print Detail List ![]() button

button

Opens a P/N Detail Print page for the selected documents. From there users can print or e-mail the document.

Schedule

The Schedule is the time limit as defined by the control. For example, TSO may have a schedule of 1000 aircraft hours. This means that the part is to be overhauled within the scheduled parameters.

Hours - P/N accumulated Aircraft hours scheduled for removal from aircraft, test on wing and/or Repair action.

Cycles - P/N accumulated Aircraft cycles scheduled for removal from aircraft, test on wing and/or Repair Action.

Days - P/N accumulated Aircraft Days or Calendar Days (dependant on the Calendar Control checkbox) scheduled for removal from aircraft, test on wing and/or Repair Action.

Date - The exact date scheduled for removal from aircraft, test on wing and/or Repair Action.

For additional information, please refer to the P/N Master, P/N Control Button Training Manual via Settings.

Note: Parts with a schedule are referred to as Hard-time items while those without a schedule are referred to as On-Condition or Soft-time items.

Actual

The Actual is the accumulated component times for a particular part. For example, a component may have a total time of 1504 hours, 345 cycles and 180 days. The actuals minus the schedule will provided the time remaining on a unit for some scheduled action/ maintenance to occur.

Hours - P/N Aircraft hours accumulated actuals.

Cycles - P/N Aircraft cycles accumulated actuals.

Days - P/N Aircraft Days or Calendar Days (dependant on the Calendar Control checkbox) accumulated actuals.

For additional information please refer to the P/N Master, P/N Control Button section of the Settings Training Manual.

Note: Although a part may not have a schedule, ALL installed serialized components do accumulate actual time. It is recommended that all serialized units contain a P/N Control for actual time monitoring (i.e. soft-time).

Reset Date

Date and time at which control information was reset for having been performed/complied.

Note: If the P/N E/C has a days controlled scheduled and does not have the Calendar Control checkbox selected, the reset date may be the A/C installed date.

Calendar Control checkbox

When the Calendar Days/Control checkbox is selected, planning calculates the controls due date based on calendar days starting from the controls Effective Date (reset/last compliance date). When the Calendar Days/Control checkbox is not selected, planning calculates the controls due date starting from the associated P/N S/N installed date (if the P/N S/Ns installed date is after the controls Effective Date).

Removal SCH / ACT

Removal Schedule (SCH) is the number of removals which will have to occur prior to a maintenance Overhaul requirement for a given Part Number. This is commonly use for the A/C P/N Removal of tires. Removal Actuals (ACT) is the number of removals which have occurred for a given Part Number. With every removal, the P/N Removal Actual value increments.

E/C Amendment

The P/N E/C related amendment as defined on the Engineering Control, General Tab.

Issued By

The authority who issued the P/N E/C as defined on the Engineering Control, General Tab.

Revision

The revision related P/N E/C effective to the part number, authorized and attached to the Repair Order as defined on the Engineering Control, General Tab.

Revision By

The user who last revised or issued the revision for the P/N E/C as defined on the Engineering Control, General Tab.

Revised Date

The P/N E/C related amendment as defined on the Engineering Control, General Tab.

_____________________________________________________________________________________

P/N Control / Shop E/C Link:

The relationship between the P/N Control and Shop E/C are now linked. This is shown in the Repair Order, Control tab.

The following P/N Control is linked to the below Shop E/C:

The P/N is placed on the Repair Order:

Go to the Repair Order, Control tab.

When the Control checkbox for FNC is selected, the Control checkbox for 95278-A is selected. Similarly, if one checkbox is de-selected, the other becomes de-selected.

The linked relationship between the P/N Control and Shop E/C can also be seen in Receiving Inspection Detail, R/O Control Tab, via Receiving Inspection which can be found in the Receiving Training manual.

Share

Share

Print

Print