Share

Share

Print

Print

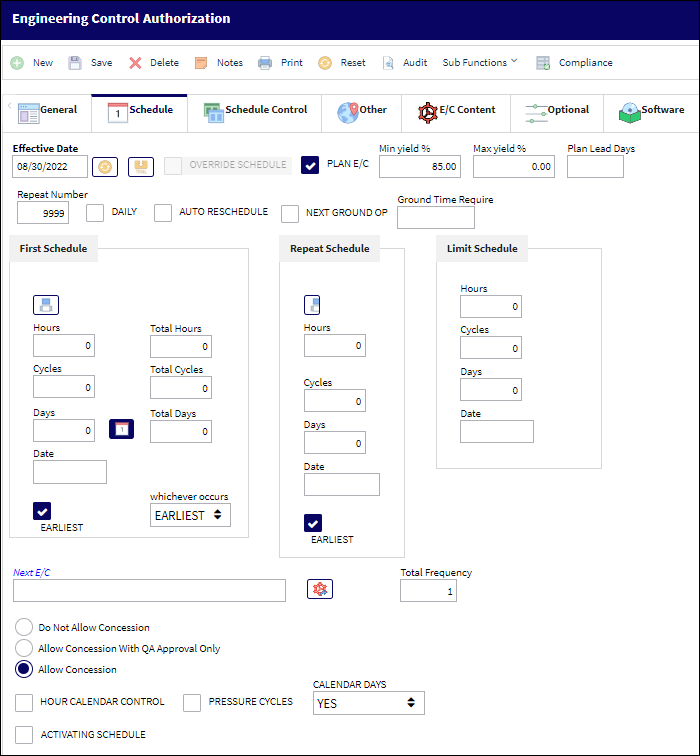

The Engineering Control Authorization, Schedule tab allows the user to view the schedule (or time limits) of the E/C prior to authorizing it. The information in this window is a copy of the Engineering Control, Schedule tab, and can be edited or updated with the appropriate security privileges.

The following information/options are available in this window:

_____________________________________________________________________________________

Effective Date

Entered as the date from which the user requires to track time on the E/C being set up unless a Total Schedule has been defined. Once the effective date is entered and the A/C or P/N Effectivity for the E/C is applied, changing the effective date on this Tab will not change the effective dates on each individual aircraft or component that the E/C is effective to. Either the Effectivity will need to be removed and re-applied, or the effective date field will need to be changed individually in the Effectivity Override window for each tail number or component.

Note: If the effective date is greater than the current date, planning will not forecast for this E/C until the effective date has been met.

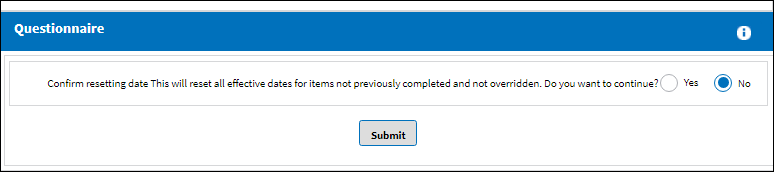

Reset Date ![]() button

button

Select the Reset Date button to reset the effective dates for items not previously complied with and/or not overridden. The following window will appear upon resetting the effective dates:

If the E/C only becomes effective following completion of another E/C or is part of a cycle of E/Cs (such as Next E/Cs A-Check1, A-Check2, etc.), then the effective date MUST be set to 00/00/0000. Based on the Effective Date, the system determines the aircraft actuals hours and cycles from that date forward. Any accumulation of flight times prior to the effective date will not be applied against the E/Cs schedule.

Override Sampling Schedule ![]() button

button

When selected the Engineering Schedule Override window appears where users can create override sampling schedules for aircraft. Applying these sampling override schedules and effectivity to certain aircraft is dependant on a Sampling Effective percentage and the sampling method selected through this window. For detailed information refer to the Override Sampling Schedule Button via the Engineering - E/C Training Manual.

Override Schedule checkbox

The Override Schedule checkbox will display as checked when an Override Schedule has been activated for the E/C. The Override ![]() button allows an alternate schedule to be activated for this E/C once a specific set of criteria is met. The alternate schedule can be applied against either the First Schedule or the Repeat Schedule of the E/C. For more information, please refer to the Override button via the Engineering Control, Schedule Tab.

button allows an alternate schedule to be activated for this E/C once a specific set of criteria is met. The alternate schedule can be applied against either the First Schedule or the Repeat Schedule of the E/C. For more information, please refer to the Override button via the Engineering Control, Schedule Tab.

Note: For date controlled E/Cs, the actual date of compliance will be changed to the Work Order's date once the Work Order is closed.

Plan E/C checkbox

The Plan E/C checkbox must be selected for the E/C to appear in the A/C Planning Query option. If de-selected, the E/C will not appear in the A/C Planning Query. This checkbox may be de-selected in the event that the user does not want to plan for an E/C that is a known daily occurrence and allows for more flexibility in planning convenience items verses mandatory items.

Note: This will default to being selected.

Warning % Due

The Warning Percentage Due field is used to make planners more effective so as not to perform an E/C too early. For example, if an E/C has a schedule of 100 days with a Warning Percentage Due of 90%, when the E/C has accumulated 90 days of actual time (usage from the last compliance) the planner will be flagged in Planning, via the Due Date/ Overdue field. For additional information, refer to Due At, via A/C Planning Details of the Planning Training Manual.

If an E/C has Lead Days, this will also influence the Warning % Due and impact the Due Date in the A/C Planning Query. Enter the percentage of the schedule that must be used before this E/C Due Date becomes highlighted in yellow within the A/C Planning Query.

Note: The default percentage that will appear is based upon the configuration of Switch ![]() PLANDUE%. The default percentage can be overridden on the specific E/C as required by entering a different value in the Warning % Due field.

PLANDUE%. The default percentage can be overridden on the specific E/C as required by entering a different value in the Warning % Due field.

Repeat Number

The number of occasions the E/C will be repeated. If the Repeat Number is set to 1, the E/C is a one time only E/C and only the First Schedule is applicable. If the Repeat Number is set to 9999, the E/C will be carried out on the First Schedule 1 time and then the Repeat Schedule indefinitely. If the Repeat Number is a specific number, such as 5, the E/C will be carried out on the First Schedule 1 time and then be repeated 4 times according to the parameters configured on the Repeat Schedule (and then terminated).Note: If the Repeat Number is set to 1, the Redo checkbox appears.

Redo E/C checkbox - Select this checkbox if a company has a one time only E/C that has been complied with, but for some reason one section of the E/C or the entire E/C must be performed again. In this scenario, the E/C must be re-opened.

Note: This checkbox is informational only.

Daily checkbox

When the Daily checkbox is selected, actual hour/cycles (time) are reset and a compliance record is written for this E/C upon the completion of the Task Cards on an 'Open' Work Order rather than at the closing of the W/O. This feature is useful for the scheduling of recurrent daily E/Cs. When selected the Auto Reschedule checkbox appears. Note that a Daily E/C should only have one Task Card linked to it. And once that one T/C is closed on the Work Order, the Daily E/C's compliance is recorded.

Note: The First and Repeat Schedule Days field on the (Schedule Tab) must be set to 1 for proper functioning of Daily E/C compliance.

Auto Reschedule checkbox

By selecting the Auto Reschedule checkbox, compliance for an aircraft Engineering Control is scheduled to take place by or before the due date/time by auto-creating a Work Order. However, if one already exists, the system adds it to the existing W/O. For this to function properly, the following two things must happen:

- At least one (1) compliance must have occurred after the selection of the checkbox

- The flight schedule must be entered and the A/C Master, Auto W/O tab must be populated

The system schedules the Work Order in accordance with the E/C’s Repeat Schedule (repeat interval) unless the aircraft is in flight at that time. If the aircraft is in flight at the due date/time, the system will look for sufficient ground time between the aircraft's scheduled flights--prior to the time that the E/C is due---when and where the Work Order can be scheduled. In this case the system refers to the schedule of the specific aircraft tail number, not just the blanket schedule found in the Engineering Control, Schedule tab. The amount of scheduled down time needed for the E/C is entered through the Ground Time Required field via the Engineering Control, Other Tab. This field is mandatory when the Auto Reschedule checkbox is selected. For detailed information refer to the Auto Reschedule Functionality topic.

Note: This checkbox only appears when the Daily checkbox is selected.

Note: This feature does not function with the Next E/C functionality. The Auto Reschedule functionality should only be used with daily E/Cs, not with larger heavy checks.

Plan Lead Days

The number of days prior to the Due Date that the event will show up in the A/C Planning Query results window in the Planning Date field. For example, if the maintenance event is due on May 20, and the Plan Lead Days field is 10, the event will show as planned for May 10.

Note: The color coding for the Planning Date field is configured in the Planning Transaction Conditions System Transaction Code, where a color can be selected.

Next Ground OP checkbox ![]()

Select this checkbox to signify if a future ground operation is necessary. Selecting this option will make the Ground Time Required field mandatory.

Ground Time Required ![]()

The amount of hours required for the next ground operation.

First Schedule section Hours/Cycles/Days

The First Schedule is the parameter and threshold for the initial occurrence and compliance of the E/C, as some E/Cs may have multiple schedules. The First Schedule only takes effect if there is no previous compliance against the E/C. The Effective Date based schedule is the initial Schedule Hours/Cycles/Days threshold parameter for this E/C. The hours/cycles/days are being calculated based on the effective date of the E/C. The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unchecked, then it will be the latest occurrence.

Note: The First and Repeat Schedules are not meant to be utilized by Shop E/Cs.

Total Schedule section Hours/Cycles/Days

The Total Hours/Cycles/Days are calculated based on whatever the E/C is effective to. If the E/C is effective to an aircraft, the Totals will be based on the Total Hours/Cycles/Days of the aircraft. If the E/C is effective to a component, the Totals will be based on the Total Hours/Cycles/Days of the component. The Total Schedule works for both A/C E/Cs and P/N E/Cs and a mixed Schedule can be utilized between the Effective Date Based Schedule and the Total Schedule. For E/Cs created with a Total Days schedule, the planning is driven by the Manufacturer Date, via A/C Master, Other 1 tab. However, if the Manufacturer Date is not populated, then Planning will be driven by the Service Date, via A/C Master, General tab.

Note: Planning Switch ![]() PN_EC_INSTDAYS and the Calendar Days field selection will determine whether a P/N E/C's Due Date is calculated based on the part's installed date or on the P/N E/C's Effective Date. For more information refer to Switch

PN_EC_INSTDAYS and the Calendar Days field selection will determine whether a P/N E/C's Due Date is calculated based on the part's installed date or on the P/N E/C's Effective Date. For more information refer to Switch ![]() PN_EC_INSTDAYS via the Planning Switches Manual.

PN_EC_INSTDAYS via the Planning Switches Manual.

Earliest checkbox - The Earliest checkbox option is selected if the E/C Schedule parameters are to be planned at the earliest occurrence. By selecting the Earliest checkbox, the schedule will be determined by which occurrence comes first: the Hours, Cycles, Days, or Date. For the latest occurrence, this checkbox should not be selected. This same logic is used independently by the parameters of the Effective Date-based Schedule (left) and of the Total Schedule (right).

Note: If a combination of the Schedule Hours, Schedule Cycles, Schedule Days, and Schedule Date fields are populated with a schedule, checking the Earliest checkbox will make the E/C become due at whichever schedule option comes due first.

First Schedule Date - The initial Schedule Date limit (due date) on this E/C. For example, an AD might have a NLT (No Later Than) Date for the First Schedule of the E/C.

Note: The First Schedule Date can now be populated and saved, even if the First Schedule A/C Total Hours/Cycles/Days is populated.

EOM checkbox - If the EOM checkbox is selected, the E/C will be due at the end of the month of the calculated due date (i.e. if an E/C is calculated to be due April 20, it will show up in Planning as due at the end of the month, i.e. April 30).

Note: This checkbox is only available when the Days field is populated.

First Schedule RIN - The Retirement Index Number is the retirement life based on fatigue damage from normal helicopter lifts and takeoffs. New components will begin with an accumulated RIN of zero that will be increased as lifts and takeoffs are performed. Operators must record the number of lifts and takeoffs and increase the accumulated RIN accordingly. When the maximum RIN or retirement flight hours is reached, whichever occurs first, the component will be removed from service. This schedule pertains to Rotor Wing aircraft. This schedule pertains to Rotor Wing aircraft. For additional information regarding Rotor Wing aircraft, refer to the Rotor Wing Aircraft Integration Process.

Note: This field only appears when Switch ![]() RINCONTROL is set to Yes. For additional information, refer to Switch

RINCONTROL is set to Yes. For additional information, refer to Switch ![]() RINCONTROL via the Engineering Switches Manual.

RINCONTROL via the Engineering Switches Manual.

Rotor Wing Schedule drop down - This drop down field allows users to select specific Rotor Wing Aircraft data to track such aircraft. This active field replaces the RIN field (above). The options are Landings, Hoist Time, Hook Time, Hoist Cycles, and Hook Cycles. Select one of the options then add a tracking amount in the field to the right of the drop down. The Rotor Wing Schedule fields are only available when a Rotor Wing Aircraft Type/Series are made effective to the E/C. Aircraft are designated as Rotor Wing when the Rotor Wing Aircraft checkbox is selected via the A/C Type/Series, General tab. To make an A/C Type/Series effective to the E/C, select the A/C Control ![]() button. For additional information regarding Rotor Wing aircraft, refer to the Rotor Wing Aircraft Integration Process.

button. For additional information regarding Rotor Wing aircraft, refer to the Rotor Wing Aircraft Integration Process.

Date to Days Calculator ![]() button - The Date to Days Calculator allows users to select future dates. Once selected, the button calculates the difference between the Effective Date and the Selected Date.

button - The Date to Days Calculator allows users to select future dates. Once selected, the button calculates the difference between the Effective Date and the Selected Date.

Override Standard Schedule ![]() button (A/C E/C) - The Override Standard Schedule

button (A/C E/C) - The Override Standard Schedule ![]() button allows an alternate schedule to be activated for the selected Aircraft E/C once a specific set of criteria is met. The alternate schedule can be applied against either the First Schedule or the Repeat Schedule of the E/C. Once the scheduling parameters that are defined in the upper fields of this window are met, the information appearing in the Override Schedule area of the window will be enacted and override the default schedule that appears on the Schedule Tab. For additional information, refer to the Override Standard Schedule (E/C) Button, via The Engineering Control, Schedule Tab.

button allows an alternate schedule to be activated for the selected Aircraft E/C once a specific set of criteria is met. The alternate schedule can be applied against either the First Schedule or the Repeat Schedule of the E/C. Once the scheduling parameters that are defined in the upper fields of this window are met, the information appearing in the Override Schedule area of the window will be enacted and override the default schedule that appears on the Schedule Tab. For additional information, refer to the Override Standard Schedule (E/C) Button, via The Engineering Control, Schedule Tab.

Override Standard Schedule ![]() button (P/N E/C) - This Override button works like the above Override button but for P/N E/Cs. For more information refer to the P/N CTL Button, via Engineering Control.

button (P/N E/C) - This Override button works like the above Override button but for P/N E/Cs. For more information refer to the P/N CTL Button, via Engineering Control.

Whichever Occurs - This dropdown field selection allows users to control which schedule option will be used between both the Effective Date-based Schedule (left) and the Total Schedule (right). Select the 'Earliest' dropdown option to have the system default to the schedule that reaches the earliest occurrence between the Hours/Cycles/Days/Date parameters (left) or the Total Hours/Total Cycles/Total Days parameters (right). Select the 'Latest' option to default to the schedule that reaches the latest occurrence between the two schedule types.

Repeat Schedule section

If the E/C has a Repeat Number greater than 1, then the Repeat Schedule is the parameter for the subsequent repetitive occurrences of the E/C for repeat compliance requirements. As with the First Schedule, some E/Cs may have multiple schedules. When an E/C has multiple schedules, the Earliest checkbox is pivotal in the configuration as the E/C may call for the compliance to be accomplished at the latest occurrence. The First Schedule information must be entered in order for the Repeat Schedule to be applicable.

Note: The First and Repeat Schedules are not meant to be utilized by Shop E/Cs.

Repeat Schedule Hours/Cycles/Days - The Repeat Schedule Hours/Cycles/Days threshold parameter for this E/C (If applicable). The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unchecked, then it will be the latest occurrence.

Note: If the EOM (End Of Month) checkbox is activated, the event will be set to the end of the month of the due date (i.e. if an event becomes due on the 21st day of a month, it will be set to the 30th or the 31st day.)

Repeat Schedule Date - The Repeat Schedule Date limit (due date) on this E/C. This is most common for an initial inspection and a follow up inspection.

Repeat Schedule RIN - Retirement Index Number. This is the Repeat Schedule RIN threshold parameter for this E/C (If applicable). The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unchecked, then it will be the latest occurrence.

Repeat Rotor Wing Schedule drop down -

Limit Schedule section

The Limit Schedule allows users to more accurately accomplish a schedule for an E/C. If the limit schedule is reached, the next time compliance is accomplished, the E/C will terminate, regardless of the number of occurrences of the Repeat No.

![]() Note: The limit schedule should not be used if there are no terminating actions on the E/C airframe life of the aircraft.

Note: The limit schedule should not be used if there are no terminating actions on the E/C airframe life of the aircraft.

Limit Schedule Hours/Cycles/Days - The Limit Schedule Hours/Cycles/Days is the termination parameter for this E/C once it has been complied with. These parameters will be compared to the aircraft's total hours/cycle/days calculated from the aircraft's Service Date (via A/C Master, General tab). (For example, after the E/C has been complied, the system will refer to the Aircraft's Service Date. If the Limit Schedule Days (1825) are met in the time between the Service Date (2007) and the Compliance Date (2014), then the E/C will be terminated once complied with.) The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unselected, then it will be the latest occurrence.

Limit Schedule Date - The Limit Schedule Date is the termination parameter for this E/C once it has been complied with. This parameter will be compared to the E/C's compliance date; if the Limit Date has been surpassed by the complied date, then the E/C will be terminated. (For example, if the Limit Date occurs before the complied date, then the E/C will be terminated once complied. If the Limit Date occurs after the Complied Date, then the E/C may remain open (depending on repeat parameter setup). The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is blank, then it will be the latest occurrence.

Limit Schedule Warning Message - The Limit Schedule Hours/Cycles/Days and Date fields cannot be less than the information in the First or Repeat Schedule fields.

Hours Calendar Control

Select this checkbox to control the E/C Schedule by calendar hours instead of flight hours.

Pressure Cycles checkbox

If the cycles limitation is controlled by Brake Landings or Pressurized Cycles (not Cycles or Touch and Go's), the Pressure Cycles checkbox is defaulted to unchecked (OFF). If checked (ON), the system will count one (1) Pressure Cycle, regardless of the number of Touch and Go's (crew training) that occurred on that Flight Log. If unchecked, the system will use the total number of cycles indicated on the flight logs.

Calendar Days

The Calendar Days drop down allows the user to determine how the E/C's due date will be calculated in the planning forecast:

- Yes - The planning forecast calculates the E/C's due date based on calendar days starting from the E/C's Effective Date (reset/last compliance date).

- No - The planning forecast calculates the E/C's due date based on calendar days starting from the P/N S/N installed date (if the P/N S/N's installed date is after the E/C's Effective Date). For P/N E/Cs Only.

No Fly - The planning forecast calculates the E/C's due date based on calendar days starting from the A/C last flight date or E/C last compliance date, whichever occurred most recently. For A/C E/Cs Only.

No Fly - The planning forecast calculates the E/C's due date based on calendar days starting from the A/C last flight date or E/C last compliance date, whichever occurred most recently. For A/C E/Cs Only.Note: The No Fly option is only available in eMRO v5 and later releases. In earlier releases, the Calendar Days field was a checkbox, providing only the Yes (selected) and No (unselected) option.

The Calendar Days drop down is only visible when Planning Switch

PN_EC_INSTDAYS is set to Yes; the Yes and No options are only applicable for P/N E/Cs. While the Switch is set to No, the Calendar Days field in not visible and the system functions as though it is always set to Yes, allowing the Days field to function as Calendar Days rather than Installed Days. The Hours and Cycles fields can also be used in conjunction with the Days field.

PN_EC_INSTDAYS is set to Yes; the Yes and No options are only applicable for P/N E/Cs. While the Switch is set to No, the Calendar Days field in not visible and the system functions as though it is always set to Yes, allowing the Days field to function as Calendar Days rather than Installed Days. The Hours and Cycles fields can also be used in conjunction with the Days field.

Next E/C

Used to set up a dependency between a group of E/Cs that will follow each other at the time of compliance. For example, if an A-Check has four phases (A1, A2, A3, A4) with each phase having its own requirements, each phases can be set up independently and then associated to the next E/C in sequential order. For the functionality to work the first E/C (A1) requires its effective date to be set and then each of the subsequent E/Cs (A2, A3, A4) must have their effective date set to null. The E/Cs repeat number should be set to 9999 so the cycle continues.

Once the initial E/C (A1) is complied with, the system will automatically change the next E/C’s (A2) effective date to the initial E/C’s (A1) compliance date. For example, E/C A1 has been set up with an effective date of 11/21/2017, and E/C A2, A3, and A4 have be set up with an effective date set to null. At the time of A1’s compliance – which, in this example is 04/28/2018 – A2’s effective date automatically changes to 04/28/2018 while A1’s effective date reverts to null; A2 is now the next E/C due and will show in a Planning Query.

The Select Next E/C Query ![]() button will display the next E/C subsequent to the current E/C being viewed.

button will display the next E/C subsequent to the current E/C being viewed.

Note: The Schedule Control Tab is a preferred method of creating E/C relationships and dependencies.

Note: It is important to select the the current phase of the Next E/C when deferring a defect.

Total Frequency

Indicates how many frequencies (occurrences) the E/C is to be performed for one frequency cycle to be completed. This field works in conjunction with the frequency field in the Schedule Control (By) tabs, where the users specifies at which frequency child E/Cs should be called on.

Note: Using frequencies allows users to create simple and/or complex relationships between a parent E/C and its called on child E/Cs. Using frequencies eliminates the need to use the Next E/C field.

Note: Please review the Engineering Control, Schedule Control Tab section of this manual for more information.

Do Not Allow Concession radio button

This option is selected so Concessions CANNOT be applied to this E/C.

Allow Concession with QA Approval Only radio button

This option is selected so Concessions CANNOT be applied to this E/C.

Allow Concession radio button

This option is selected so Concessions can be applied to this E/C.

Note: Please review the Concession Registry section in the Technical Records manual for more information.

First Schedule Override A/C Hours/Cycles

Allows user to override the First Schedule Hours/Cycles with the Override Schedule which will become effective if the A/C or P/N has accumulated the configured amount of hours and/or cycles.

Repeat Schedule Override A/C Hours/Cycles

Allows user to override the Repeat Schedule Hours/Cycles with the Override Schedule which will become effective if the A/C or P/N has accumulated the configured amount of hours and/or cycles. For more information regarding the Schedule Override, refer to the Override Standard Schedule (E/C) ![]() button.

button.

_____________________________________________________________________________________

Share

Share

Print

Print