Share

Share

Print

Print

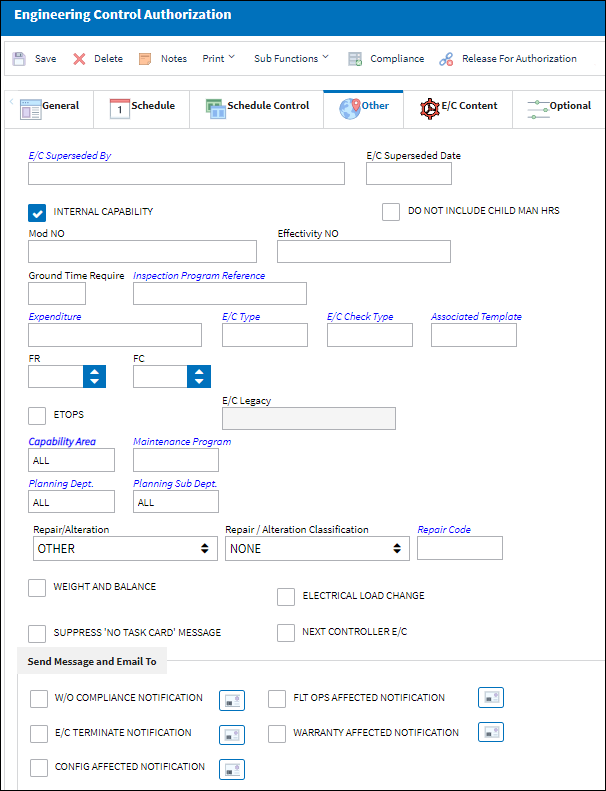

The Engineering Control Authorization, Other Tab allows the user to enter and view additional information for an E/C.

The following information/options are available in this window:

_____________________________________________________________________________________

E/C Superseded By

The E/C entered in this field supersedes the original E/C selected into. This feature is used to phase in one E/C and phase out and terminate the current E/C selected. The E/C that is being superseded will be identified as such (flagged in red text) on the E/C General Tab.

E/C Superseded Date

The date that the superseding E/C takes effect.

Internal Capability checkbox

This checkbox indicates hat the work can be carried out internally as opposed to having a third party maintenance organization carry it out. This field is informational only.

Note: The Internal Capability checkbox is selected by default.

Do Not Include Child Man Hrs checkbox

When selected, the Man Hours calculation for Planning will not include the Man Hours for any Child E/Cs (Called On E/Cs). The checkbox also applies to the Work Order Man Hours in Planning.

Ground Time Require

The amount of time needed for an aircraft to be on the ground in order to comply with the E/C. The time format is user defined by hours (0.00). This information appears on the A/C Planning Query results window as GTR (Ground Time Required).

Inspection Program Reference

This field allows users to set a reference for all MPD tasks during the import process.

Expenditure

The G/L accounts linked to the expenditure code will be impacted when the E/C, and its associated Task Cards, are added to a Work Order. All materials issued, labor actuals, and expenses performed against this E/C impacts the expenditure codes financially. If the E/C does not have a defined expenditure code the system will use the W/O expenditure code to capture and record all financial impacts. Financial transactions are recorded and available for view via the Journal Entry Query. Expenditure Codes may be created via G/L Interface/Update/Journal Entries Expenditure in the Creating a New Expenditure Code. For more information, please refer to the Creating a New Expenditure Code section of the G/L Interface manual.

This code is mandatory in the Work Order. The user will not be able to create a Work Order without defining the Expenditure Code.

ETOPS checkbox

Indicates that this E/C is ETOPS rated with an extended range allotted to the aircraft.

E/C Type

The Engineering Control Type.

E/C Check Type

This field allows the user to enter a system transaction code that sorts the Aircraft Check Status print contents based on the the configuration of the E/C Check Type transaction code. The Group/Sort Order field of the transaction code will sort E/Cs from shortest to longest check type based on their numeric value. For more information, refer to E/C Check Type via the Engineering Transaction Codes Training Manual.

Note: This functionality is part of a customized print and is therefore not applicable for most users.

Associated Template ![]()

This field contains a selection of Templates that can be used in conjunction with the E/C.

FR (Fatigue Rate)

The Fatigue Rate being recorded by this E/C. This field is used to calculate fatigue schedules along with the Average Flight Time (AFT) and Basic Flight Time (AFB) parameters listed for specific Aircraft Type/Series. This functionality is used for Airbus aircraft only and should be provided by the manufacturer. For more information refer to Engineering Fatigue via the Engineering Training Manual.

FC (Fatigue Cycle)

The Fatigue Cycles being recorded by this E/C. This field is used to calculate Fatigue schedules along with the Average Flight Time (AFT) and Basic Flight Time (AFB) parameters listed for specific Aircraft Type/Series. This functionality is used for Airbus aircraft only and should be provided by the manufacturer. For more information refer to Engineering Fatigue via the Engineering Training Manual.

E/C Legacy

The legacy system's E/C name. This field functions as a mapping between a previous carrier's E/C name and the target carrier's E/C name. This field is not for manual input; it is populated automatically by an interface and is informational only.

![]() This field is part of a customized interface and is not available for all customers.

This field is part of a customized interface and is not available for all customers.

Capability Area

The Capability Area identifies where a maintenance task can be accomplished in association with the customer's internal capabilities (e.g., a particular E/C can only be accomplished during a heavy maintenance visit at a heavy maintenance capable Site). The Capability Area can be assigned for E/Cs, P/N Controls, and Defect Reports. However, a maintenance task with any Capability Area can be scheduled on Work Orders at Sites that have their Capability Area set to 'ALL'. For more information regarding the Capability Area, refer to the Capability Area section of the Planning Transaction Code Manual.

Maintenance Program

The part's associated Maintenance Program.

Planning Dept.

The Planning Department Code to assist the Planning department in filtering and planning tasks.

Note: When Switch ![]() PLANDEPT is set to Yes, the Planning Dept and Planning Sub Dept fields become mandatory in the following windows: P/N Control, Engineering Control/ Other tab, Defect Report/ Defer tab. When set to No, the Planning Dept and Planning Sub Dept fields are not mandatory. For more information, refer to Switch

PLANDEPT is set to Yes, the Planning Dept and Planning Sub Dept fields become mandatory in the following windows: P/N Control, Engineering Control/ Other tab, Defect Report/ Defer tab. When set to No, the Planning Dept and Planning Sub Dept fields are not mandatory. For more information, refer to Switch ![]() PLANDEPT via the Planning Switches Training Manual.

PLANDEPT via the Planning Switches Training Manual.

Planning Sub Dept

The Planning Sub Department code to assist the Planning department in filtering and planning tasks.

Note: When Switch ![]() PLANDEPT is set to Yes, the Planning Dept and Planning Sub Dept fields become mandatory in the following windows: P/N Control, Engineering Control/ Other tab, Defect Report/ Defer tab. When set to No, the Planning Dept and Planning Sub Dept fields are not mandatory. For more information, refer to Switch

PLANDEPT is set to Yes, the Planning Dept and Planning Sub Dept fields become mandatory in the following windows: P/N Control, Engineering Control/ Other tab, Defect Report/ Defer tab. When set to No, the Planning Dept and Planning Sub Dept fields are not mandatory. For more information, refer to Switch ![]() PLANDEPT via the Planning Switches Training Manual.

PLANDEPT via the Planning Switches Training Manual.

Repair/Alteration

Defines if the record requires Repair or Alteration.

Other - The component is neither altered or repaired. This is a miscellaneous option.

Alteration - This compliance of the E/C will alter the component (i.e. the removal or addition of sub-components).

Repair - The compliance of the E/C will repair the component (i.e. a structural component has sheet metal work completed to strengthen the integrity of the structure).

Repair/Alteration Classification

The level of Repair/Alteration (Major, Minor) required for this E/C.

Note: The Repair/Alteration Classification field is only visible if Repair or Alteration is selected in the Repair/Alteration field.

Repair Code

The repair code related to the E/C. For more information, refer to Repair Code via Order Transaction Codes Training Manual.

Weight and Balance checkbox

Select this checkbox to enter weight and balance information related to this E/C. When selected, the Weight On and Weight Off fields appear.

Weight On - The amount of weight added to the A/C once the E/C work has been accomplished.

Weight Off - The amount of weight removed from the A/C once the E/C work has been accomplished.

Suppress 'No Task Card' Message checkbox

Select this checkbox to suppress the following message from appearing when an E/C with no Task Card is added to a Work Order.

![]()

Electrical Load Change checkbox

Select this checkbox if E/C compliance will cause any changes to the power on the aircraft, due to electrical unit changes.

Note: This checkbox is for information only.

Revision Assigned To

The employee the revision of the E/C is assigned to.

W/O Compliance Notification

Select this checkbox to have a system notification automatically sent whenever the E/C is complied with through the post completion of a work order. The user who the notification is sent to is configured through the Select Notification ![]() button to the right of the checkbox.

button to the right of the checkbox.

E/C Terminate Notification

Select this checkbox to send a notification to specific users informing them when the E/C has been terminated. This notification will contain detailed information regarding the E/C. To configure the notification select the Select Notification ![]() button to the right of this checkbox.

button to the right of this checkbox.

Config Affected Notification

Select this checkbox to send a notification to specific users informing them that the configuration was affected for this E/C once it is revised, released, and/or deleted. This notification will contain detailed information regarding the E/C. To configure the notification select the Select Notification ![]() button to the right of this checkbox.

button to the right of this checkbox.

Flt Ops Affected Notification

Select this checkbox to send a notification to specific users informing them that Flt Ops were affected for this E/C once it is revised, released, and/or deleted. This notification will contain detailed information regarding the E/C. To configure the notification select the Select Notification ![]() button to the right of this checkbox.

button to the right of this checkbox.

Warranty Affected Notification

Select this checkbox to send a notification to specific users informing them that the warranty was affected for this E/C once it is revised, released, and/or deleted. This notification will contain detailed information regarding the E/C. To configure the notification select the Select Notification ![]() button to the right of this checkbox.

button to the right of this checkbox.

Select Notification button

Select this button to configure the type of notification to be sent regarding any of the aforementioned appropriate checkboxes. When selected, the System Notification window pops up. For more information, refer to Setup - System Notification via the Settings Training Manual.

_____________________________________________________________________________________

Share

Share

Print

Print