Share

Share

Print

Print

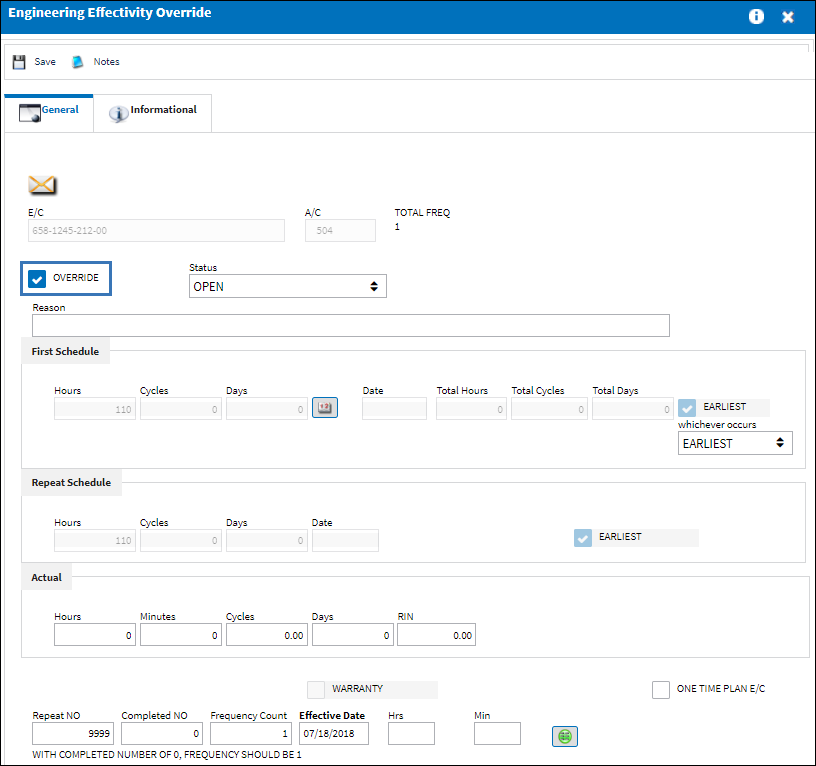

The Engineering Effectivity Override window allows users to update E/C information for individual A/C tail numbers, such as Status, Repeat NO, Completed NO, Frequency Count, Effective Date, and Hrs/Min. Updates may be required to ensure that the A/C is tracking against the E/C properly and that it is forecasting correctly in the Planning module.

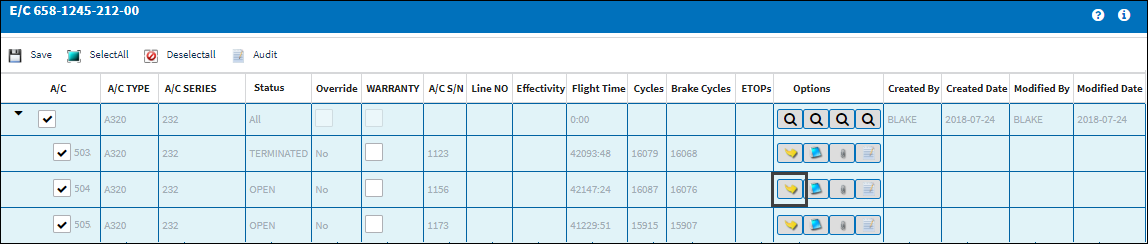

From the E/C window, expand the A/C Type/Series and use the Select ![]() button to select into an A/C.

button to select into an A/C.

An Engineering Effectivity Override window appears. Select the Override checkbox to make edits and update available fields.

Note: The Yes/No and Config Other field settings of Switch ![]() ECVIAREV will determine if changes can be made to the E/C effectivity outside of the E/C revision process.

ECVIAREV will determine if changes can be made to the E/C effectivity outside of the E/C revision process.

![]() System configuration, user security, E/C revision status, and path taken to access the Engineering Effectivity Override window (i.e. Engineering Control Selection, Engineering Control Authorization Management) will determine which fields will be available to edit when the Override checkbox is selected.

System configuration, user security, E/C revision status, and path taken to access the Engineering Effectivity Override window (i.e. Engineering Control Selection, Engineering Control Authorization Management) will determine which fields will be available to edit when the Override checkbox is selected.

The following information/options are available in this window:

_____________________________________________________________________________________

E/C

The Engineering Control that specifies aircraft or component scheduled maintenance intervals.

A/C

The Aircraft registration number. All items within this window will only pertain to this A/C and may not match the default blanket schedule on the Engineering Control, Schedule Tab due to override information added.

Total Freq

Displays at which frequency the E/C is currently on (out of the E/Cs total frequency, as defined in the E/C Schedule tab). For additional information refer to the Engineering Control, Schedule Tab, via the Engineering - E/C Training Manual.

Override checkbox

Allows for the user to update many fields within this window and apply an alternate schedule against the E/C for a particular A/C tail number or P/N S/N. If the Override checkbox remains selected, any changes against the blanket schedule (Engineering Control, Schedule Tab) will not affect the A/C tail number or P/N S/N that has the checkbox selected; the Override A/C tail number or P/N S/N will only follow the schedule as defined here on the Engineering Effectivity Override, General Tab.

Note: The configuration of switch ![]() ECVIAREV determines the accessibility of this checkbox as well as which information can be edited/updated in this window. The same functionality is also available when this window is accessed through the Engineering Control Supervisor window.

ECVIAREV determines the accessibility of this checkbox as well as which information can be edited/updated in this window. The same functionality is also available when this window is accessed through the Engineering Control Supervisor window.

Status

The current E/C status for the Aircraft. For additional information regarding definition of each status, see the Engineering Control, General Tab, via the Engineering - E/C Training Manual.

Note: If the status is manually changed to a status which prevents the E/C from appearing in Planning Forecast, the Reason field will become mandatory.

Note: When Switches ![]() ECAUTH and ECVIAREV are set to Yes, and the status is changed to a different status from the main level E/C status, a soft warning will appear. This soft warning also appears at the revision level.

ECAUTH and ECVIAREV are set to Yes, and the status is changed to a different status from the main level E/C status, a soft warning will appear. This soft warning also appears at the revision level.

Reason

The Reason field allows for additional notations to be added against the Engineering Effectivity Override for a particular A/C.

First Schedule

The First Schedule is the parameter and threshold for the initial occurrence and compliance of the E/C, as some E/Cs may have multiple schedules. The First Schedule only takes effect if there is no previous compliance against the E/C. The Effective Date based schedule is the initial Schedule Hours/Cycles/Days threshold parameter for this E/C. The hours/cycles/days are being calculated based on the effective date of the E/C. The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unchecked, then it will be the latest occurrence. For additional information on the First Schedule field, refer to the Engineering Control, Schedule Tab, via the Engineering - E/C Training Manual.

Note: First Schedule within the Engineering Effectivity Override window only applies to the selected A/C and E/C. If the Override checkbox remains selected then this A/C will have its own schedule and will not be reset/changed by any changes made on the blanket schedule (Engineering Control, Schedule Tab).

![]() The Schedule fields are security controlled via Engineering/ Update/ Engineering Control Selection/ E/C Edit Schedule. The same functionality is also available when this window is accessed through the Engineering Control Supervisor window. For more information refer to the Security Explorer via the System Administration Training Manual.

The Schedule fields are security controlled via Engineering/ Update/ Engineering Control Selection/ E/C Edit Schedule. The same functionality is also available when this window is accessed through the Engineering Control Supervisor window. For more information refer to the Security Explorer via the System Administration Training Manual.

Date to Days Calculator ![]() button

button

The Date to Days Calculator allows users to select future dates. Once selected, the button calculates the difference between the Effective Date and the Selected Date.

Repeat Schedule

If the E/C has a Repeat Number greater than 1, then the Repeat Schedule is the parameter for the subsequent repetitive occurrences of the E/C for repeat compliance requirements. As with the First Schedule, some E/Cs may have multiple schedules. When an E/C has multiple schedules, the Earliest checkbox is pivotal in the configuration as the E/C may call for the compliance to be accomplished at the latest occurrence. The First Schedule information must be entered in order for the Repeat Schedule to be applicable. For additional information on the Repeat Schedule field, refer to the Engineering Control, Schedule Tab, via the Engineering - E/C Training Manual.

Note: Repeat Schedule within the Engineering Effectivity Override window only applies to the particular A/C and E/C. If the Override checkbox remains selected then this A/C will have its own schedule and will not be reset/changed by any changes made on the blanket schedule (Engineering Control, Schedule Tab).

Actual

The user may enter accumulated flight times applicable to the E/C prior to the A/C In Service Date. The Actuals (Hours, Cycles and Days) will be added to any flight times recorded since the A/C last compliance date and/or Effective Date for the E/C in Planning to produce the A/Cs E/C Actuals.

Note: The Engineering Effectivity Override Actual fields are only used for the A/C's initial induction into the system. This feature is typically not employed for the induction of new aircraft from the manufacturer.

![]() The Actuals fields are security controlled via Engineering/ Update/ Engineering Control Selection/ E/C Edit Actuals. The same functionality is also available when this window is accessed through the Engineering Control Supervisor window. For more information refer to the Security Explorer, via the System Administration Training Manual.

The Actuals fields are security controlled via Engineering/ Update/ Engineering Control Selection/ E/C Edit Actuals. The same functionality is also available when this window is accessed through the Engineering Control Supervisor window. For more information refer to the Security Explorer, via the System Administration Training Manual.

Earliest checkbox

The Earliest checkbox option is selected if the E/C Schedule parameters are to be planned at the earliest occurrence. By selecting the Earliest checkbox, the schedule will be determined by which occurrence comes first: the Hours, Cycles, Days, or Date. For the latest occurrence, this checkbox should not be selected. This same logic is used independently by the parameters of the Effective Date-based Schedule (left) and of the Total Schedule (right).

Note: If a combination of the Schedule Hours, Schedule Cycles, Schedule Days, and Schedule Date fields are populated with a schedule, checking the Earliest checkbox will make the E/C become due at whichever schedule option comes due first.

Warranty checkbox

This will show as selected to indicate that warranty information is applied for a particular tail number of this A/C Type/Series.

One Time Plan E/C checkbox

Indicates that the Child E/Cs schedule is being overridden as a one-time only E/C for the selected Aircraft. For Child E/Cs that are adopting its parent E/Cs schedule for a Work Order, if the Child E/C is transferred from that Work Order to another W/O, then this checkbox is selected for the W/Os specific Aircraft. Once the Child E/C is complied with for that Aircraft, the checkbox is automatically deselected. The One Time Plan checkbox should only be used through the functionality of Switch ![]() ECCHLDTRC (when set to Yes). The functionality of this checkbox is for correcting purposes through the switch's automated functionality, and should therefore not be selected manually from the override window.

ECCHLDTRC (when set to Yes). The functionality of this checkbox is for correcting purposes through the switch's automated functionality, and should therefore not be selected manually from the override window.

Note: When Switch ![]() ECCHLDTRC is set to Yes, when a Child E/C is transferred or canceled (via Task Card cancelation) from a W/O, the Child E/C will set to One Time Plan automatically. After the Child E/C takes its next compliance, the One Time Plan checkbox will automatically be de-selected. This functionality works if the Child E/C has it own schedule; if not, the system will prevent the transfer/cancel.

ECCHLDTRC is set to Yes, when a Child E/C is transferred or canceled (via Task Card cancelation) from a W/O, the Child E/C will set to One Time Plan automatically. After the Child E/C takes its next compliance, the One Time Plan checkbox will automatically be de-selected. This functionality works if the Child E/C has it own schedule; if not, the system will prevent the transfer/cancel.

Note: The Child E/C must be brought onto the Work Order via a Parent E/C for this to function correctly.

Repeat NO

The number of occasions the E/C will be repeated. If the Repeat Number is set to 1, the E/C is a one time only E/C and only the First Schedule is applicable. If the Repeat Number is set to 9999, the E/C will be carried out on the First Schedule 1 time and then the Repeat Schedule indefinitely. If the Repeat Number is a specific number, such as 5, the E/C will be carried out on the First Schedule 1 time and then be repeated 4 times according to the parameters configured on the Repeat Schedule (and then terminated).Complete NO

The number of times that the E/C has been complied with against the A/C.

Note: The Frequency Count and Completed NO fields must match the Completed/Frequency Flag for the proper E/C Called On functionality to work.

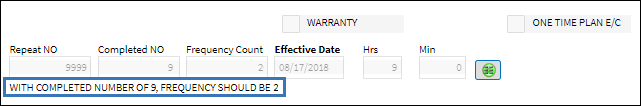

Frequency Count

Displays at which frequency the E/C is currently on (out of the E/Cs total frequency, as defined in the E/C Schedule tab). For additional information refer to the Engineering Control, Schedule Tab via the Engineering - E/C Training Manual.

Note: The Frequency Count and Completed NO fields must match the Completed/Frequency Flag for the proper E/C Called On functionality to work.

Effective Date Hrs/ Min

The Effective Date is the date from which hours/cycles/days accumulate. It is used to calculate times accrued and due dates in the Planning Query.

Note: If the effective date is greater than the current date, planning will not forecast for this E/C until the effective date has been met.

Display Compliance History ![]() button

button

Select to view all historical compliance records for this E/C against the A/C. For additional information, refer to the Engineering Control Display Compliance History button, via the Engineering - E/C Training Manual.

Completed/ Frequency flag

The Completed/Frequency flag indicates that with the Completed NO being 'X' then the Frequency Count should be 'Y'. For proper E/C Called On functionality it is required that the Completed NO and Frequency Count fields match the Completed/Frequency Flag. For example, if an E/C has a frequency of 4, after being complied with 9 times the Frequency Count should be 2.

![]()

_____________________________________________________________________________________

For additional information regarding the utilization of the functionality, refer to the following:

Share

Share

Print

Print