Share

Share

Print

Print

The Effectivity of the GSE E/C can be applied to either GSE Items or parts (components).

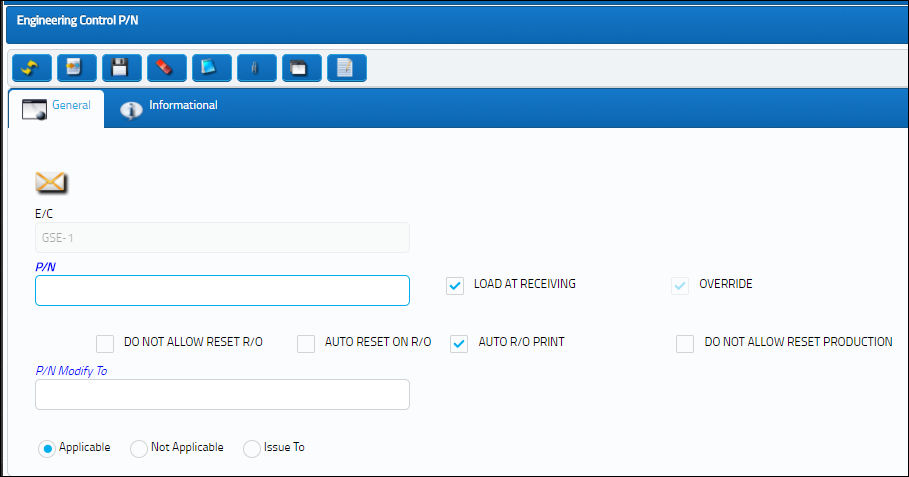

Select the P/N CTL ![]() button to apply P/N Effectivity to the currently selected GSE E/C. When selected, the Engineering Control P/N window appears.

button to apply P/N Effectivity to the currently selected GSE E/C. When selected, the Engineering Control P/N window appears.

Note: For the P/N E/C to be called via a P/N Control onto a work package, the P/N S/N must have effectivity at the P/N E/C level. For additional information, refer to the P/N Control Button, via the P/N Master of the Settings Training Manual.

The Override ![]() button is used to apply specific Serial Number Effectivity if required.

button is used to apply specific Serial Number Effectivity if required.

The following information/options are available in this window:

_____________________________________________________________________________________

E/C

The Engineering Control that specifies aircraft or component scheduled maintenance intervals.

P/N

This is the Part Number associated to the E/C.

Note: P/N E/Cs need to be set up for main parts as well as their interchangeable parts. Newly created P/Ns that are interchangeable with a main P/N will not be associated to the same E/Cs as the main part. Each E/C must be manually associated to the interchangeable part through this window.

Load At Receiving checkbox

Select this checkbox if new Part Numbers (Inventory) initially entered into the system should have Effectivity linked to this E/C. Whenever a part linked to this P/N E/C is initially entered into the database (be it through P/O, L/O, P/N Initial Load, etc.), the Load at Receiving checkbox comes into effect. This checkbox applies to on-wing receiving as well. This checkbox can be auto selected for a specified E/C Category if the Load At Receiving checkbox is selected via the E/C Category Transaction Code.

Note: This checkbox is strictly for the Purchase Order, Loan Order, and Engineering Control receiving and the P/N Initial Load feature. Repair Order for already existing Goods Received Batch Numbers (GRN) where the P/N was changed will apply the effectivity, but the E/C can be deselected as required.

Override checkbox

Select this checkbox if this Part Number has been overridden in the past via the Override ![]() button. Select the Override

button. Select the Override ![]() button to view specific P/N S/N history.

button to view specific P/N S/N history.

Follow GRB checkbox

When the Follow GRB checkbox is selected the system will continue to track the E/C for that GRB (Goods Received Batch) regardless of any changes made to any P/N S/N that is effective to the E/C including any Override schedules.

Note: This checkbox only appears when Switch ![]() FOLLOWGRB is set to Yes.

FOLLOWGRB is set to Yes.

Do Not Allow Reset R/O checkbox

Select this checkbox to indicate that this record should not be reset (i.e. not selected for compliance) when associated with a Repair Order. When this Part Number is on a Repair Order, the default setting for this is that there will be no checkbox available in the control window to be selected or de-selected, it is not visible.

Auto Reset On R/O checkbox

Select this checkbox to indicate that this E/C should be reset (selected for compliance) when this E/C is associated with a Repair Order. This will be the default setting when this Part Number is on a Repair Order. This option can be overridden at the Repair Order level and de-selected.

Note: All P/N E/Cs of Mandatory Classification will receive automatic E/C Compliance upon receipt of Vendor Repair Order.

Auto R/O Print

If this checkbox is selected, the E/C will automatically be printed on Repair Orders that are issued for the part indicated. This will be the default setting when this Part Number is on a Repair Order. This option can be overridden at the Repair Order level and deselected.

Do Not Allow Reset Production

Select this checkbox to indicate that this E/C should not be reset (i.e. not selected for compliance) when this E/C is associated with a Production Work Order.

P/N Modify To

When a P/N is entered in this field, (when an existing P/N has this E/C associated and the E/C is complied with, upon receiving the P/N), the P/N will convert to the P/N Modified To Number. When populated, the Modify To in Production/Shop Checkbox appears. This is a user defined option.

Note: The new P/N must be set up in the P/N Master via the Settings module.

Modify To in Production/Shop checkbox - Select this checkbox allows the user to modify the part number via a Production/Shop Work Order.

Applicable radio button

Select if this P/N is applicable to this particular record.

Not Applicable radio button

Select if this P/N is applicable to this particular record.

Note: This can be used when a P/N was at one time applicable. Instead of deleting the P/N from the window, change the selection to Not Applicable. This will maintain history of the E/C and P/N.

Issue To radio button

Select if the record has been issued to this P/N, but does not need to be put into effect.

Engineering Control Range ![]() button

button

Select this button to access the Engineering Control Range window. This option allows the user to apply effectivity to a serial number range with applicable status and reason information for in range and out of range serial numbers. For additional information, refer to the E/C P/N Range Button, via P/N CTL Button in the Engineering - E/C Training Manual.

P/N Software to Upload at Compliance ![]() button

button

The P/N Software to Upload at Compliance ![]() button allows the user to view the Software parts from the P/N Software Configuration that are associated with the part number. The user also has the option to enable the software part to be uploaded once the E/C has been complied with.

button allows the user to view the Software parts from the P/N Software Configuration that are associated with the part number. The user also has the option to enable the software part to be uploaded once the E/C has been complied with.

This button is only visible if the P/N that the E/C is associated to is linked to a P/N Software Configuration. For more information refer to the P/N Software Configuration functionality via the Settings Training Manual.

Note: Switch ![]() UPDATESWCOMPLEC must be set to No for this button to appear in this window.

UPDATESWCOMPLEC must be set to No for this button to appear in this window.

For additional information refer to the P/N Software to Upload at Compliance Button, via the Engineering Controls Button of the Engineering - E/C Training Manual.

_____________________________________________________________________________________

Share

Share

Print

Print