Share

Share

Print

Print

The Auto Line W/O Generation ![]() button allows users to manually create Line Work Orders for an aircraft where the Line Work Orders would otherwise be auto generated via the system database jobs. The Auto Line W/O Generation function is useful in the event that an aircraft that does not exist in the system requires maintenance, or, perhaps, the maintenance cannot wait until the job to auto create Line Work Orders is ran at the end of the month. The system validates whether there are any Open Line Work Orders for the aircraft. If there are Open Line Work Orders for the aircraft, the system will not create duplicate Line Work Orders.

button allows users to manually create Line Work Orders for an aircraft where the Line Work Orders would otherwise be auto generated via the system database jobs. The Auto Line W/O Generation function is useful in the event that an aircraft that does not exist in the system requires maintenance, or, perhaps, the maintenance cannot wait until the job to auto create Line Work Orders is ran at the end of the month. The system validates whether there are any Open Line Work Orders for the aircraft. If there are Open Line Work Orders for the aircraft, the system will not create duplicate Line Work Orders.

![]() Note: This button is security controlled at the W/O header level via Production/ Update/ W/O/ W/O Sel Sub Functions. For more information refer to the Security Explorer via the System Administration Training Manual.

Note: This button is security controlled at the W/O header level via Production/ Update/ W/O/ W/O Sel Sub Functions. For more information refer to the Security Explorer via the System Administration Training Manual.

This feature works in conjunction with the Auto Create Line Work Orders button found in Settings/ Aircraft/ Auto W/O tab. The user must first set up the parameters for the Line Work Order in the A/C Master prior to selecting the Auto Line W/O Generation ![]() button via the Production module. If the parameters have not been set up, the system will not create a Line Work Order for an aircraft. For additional information, refer to the Auto Create Line Work Orders button, via the Aircraft Master.

button via the Production module. If the parameters have not been set up, the system will not create a Line Work Order for an aircraft. For additional information, refer to the Auto Create Line Work Orders button, via the Aircraft Master.

![]() Note: When the Auto Line W/O Generation button is selected, a Third Party Line W/O will be created with a Non Routine Task Card. The user must first set up the parameters for the Line Work Order in the A/C Master with the TPW checkbox selected via the Auto Create Line Work Orders button, in the Aircraft Master, Auto W/O tab.

Note: When the Auto Line W/O Generation button is selected, a Third Party Line W/O will be created with a Non Routine Task Card. The user must first set up the parameters for the Line Work Order in the A/C Master with the TPW checkbox selected via the Auto Create Line Work Orders button, in the Aircraft Master, Auto W/O tab.

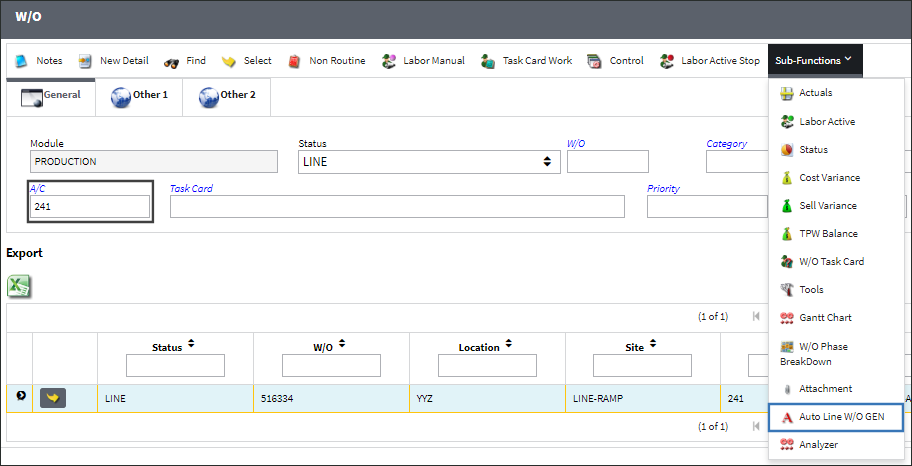

From the Work Order Header, specify an aircraft and select the Auto Line W/O Generation ![]() button.

button.

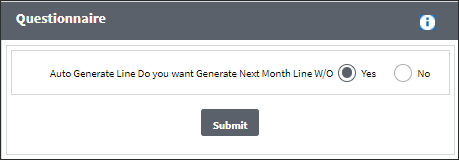

The system displays the following prompt. Select 'Yes' and 'Submit' to generate the Line Work Order.

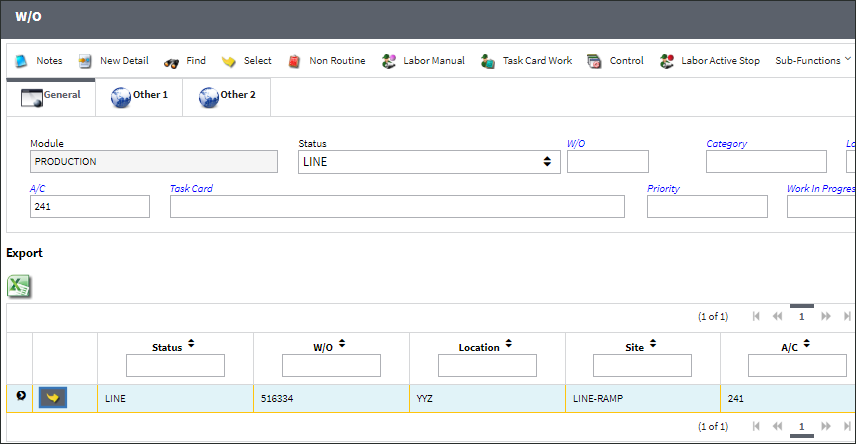

A Line Work Order is generated based on the parameters set up via the A/C Master.

Select into the detail of the Line Work Order.

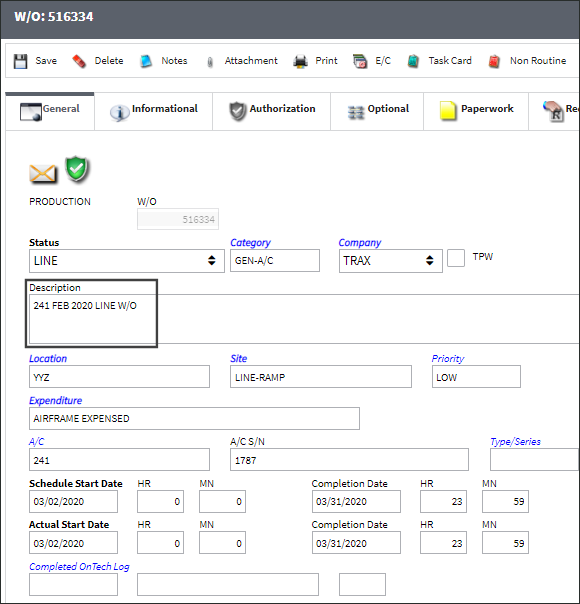

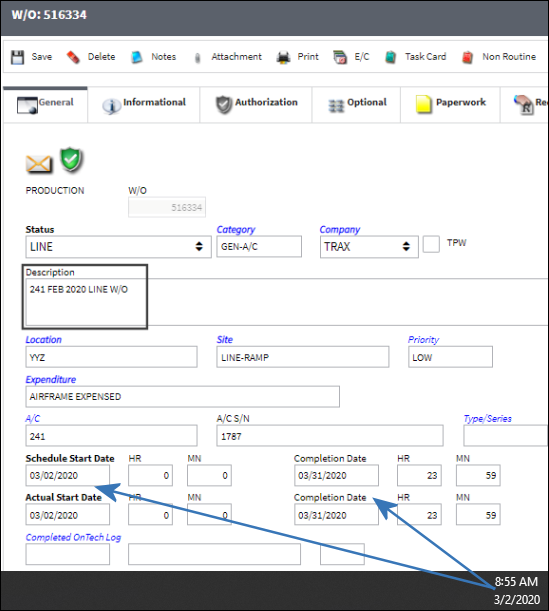

The Description of the Work Order is defaults to the A/C number, the month & year, followed by "LINE W/O," as illustrated below:

Note that the generation date equals the Schedule Start Date and Actual Start Date of the Line Work Order. The Completion Dates are defaulted to the end of the month.

Share

Share

Print

Print