Share

Share

Print

Print

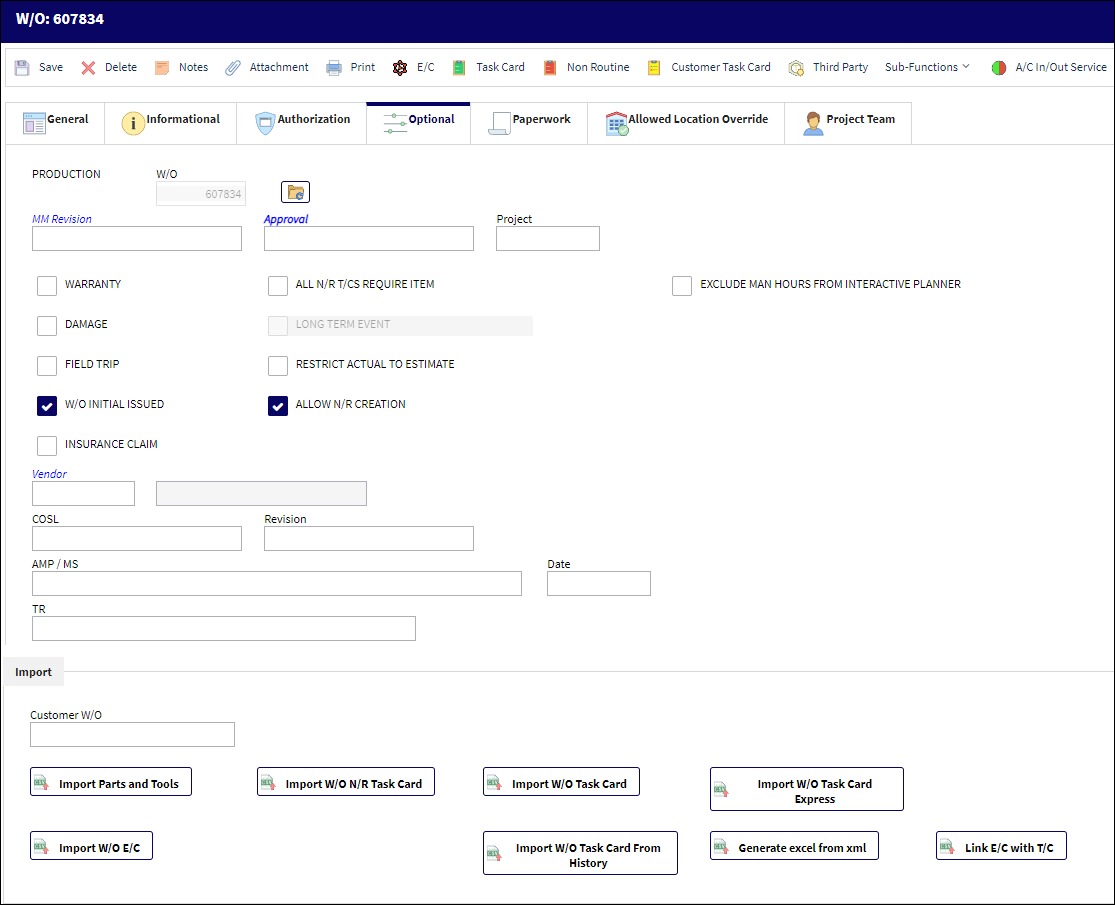

The Work Order Detail, Optional tab contains the following additional options.

The following information/options are available in this window:

_____________________________________________________________________________________

Production W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance. This field is generated automatically once the W/O is created.

Re-Open All Financial Transactions ![]() button

button

Select this button to re-open any closed Work Orders in order to reverse financial transactions. For additional information, refer to the Re-Open All Financial Transactions Button, via the Work Order Detail, Optional Tab of the Production Training Manual.

Note: This option does not work for Third Party Work Orders.

MM Revision

The current Maintenance Manual Revision.

Approval

The aviation authority. (i.e. FAA Federal Aviation Administration)

![]() Note: This field will automatically populate with the Approval value entered in the Work Order Category Transaction Code. For additional information, please refer to W/O Category via the Production Transaction Codes module.

Note: This field will automatically populate with the Approval value entered in the Work Order Category Transaction Code. For additional information, please refer to W/O Category via the Production Transaction Codes module.

Project

The Project associated to the Work Order. Free text field for alphanumerical information. This field is informational only.

Warranty checkbox

This is checked if the Work Order is associated with a warranty condition. This is informational only.

All N/R T/Cs Require Item checkbox

When selected, all Non-Routine Task Cards attached to this Work Order must contain Items in order to print the N/R T/C.

DEFNRTCITEM - When set to Yes, the 'All N/R T/Cs Require Item' checkbox is selected by default in the Work Order Detail, Optional tab when a new Work Order is created. This checkbox prevents users from printing a Work Order's Non-Routine Task Card if it does not contain Items.

DEFNRTCITEM - When set to Yes, the 'All N/R T/Cs Require Item' checkbox is selected by default in the Work Order Detail, Optional tab when a new Work Order is created. This checkbox prevents users from printing a Work Order's Non-Routine Task Card if it does not contain Items.

Damage checkbox

This is checked if the Work Order is associated with a damaged condition. This is informational only.

Field Trip checkbox

This is checked if the Work Order is performed at a location other than a non-maintenance location or contract maintenance available location. This is informational only.

Restrict Actual To Estimate checkbox

When selected, the user may not update the Man Hours via W/O Task Card Manual Labor to surpass the Man Hours entered via the Work Order Task Card Item. For additional information, see Restrict Actual To Estimate checkbox via Work Order Detail.

W/O Initial Issued checkbox

Select to expense the rotable Fixed Asset if the rotable part is being installed for the first time. This checkbox is intended to allow the removal of Fixed Assets from the F/A Registry when the parts installed on the Aircraft will not be removed. Because another F/A would not take their place on the F/A Registry, they need to be removed (for example, when installing a new seat).

Note: All of the parts assigned to a Work Order where the W/O Initial Issued checkbox has been selected will be removed from the Fixed Asset Registry once the Work Order is closed. The removed F/A may not be the one on the Initial Issued Work Order and installed on the Aircraft. The system will follow the FIFO method (First In, First Out) to remove the F/A from the Registry.

Allow N/R Creation checkbox

Select this checkbox to allow the system to create a Non-Routine Task Card for the specified Work Order. If this checkbox is deselected, and the user attempts to create a Non-Routine Task Card, the system will generate a hard warning which will prevent the NRTC from being created.

Note: This checkbox is selected by default when creating a new Work Order.

Insurance Claim checkbox

This is checked when the Work Order is associated to an Insurance Claim. When selected, the Claim Number field appears.

Claim Number - The Insurance claim number, which applies to the part of the order.

Exclude Man Hours from Interactive Planner checkbox

When selected, required Man Hours against the W/O's Task Cards will not calculated in the Interactive Planner. When not selected, the Man Hours will be calculated in the Interactive Planner. By default, this checkbox is not selected.

Note: Man Hours are only displayed in the Interactive Planner for Work Orders when Planning Switch ![]() INTERACTPLANMANHOURS is set to Yes and the Display Man Hours checkbox is selected in the Interactive Planner. For more information, refer to the Planning Switches Manual and the Interactive Planning Window via the Planning Control Module.

INTERACTPLANMANHOURS is set to Yes and the Display Man Hours checkbox is selected in the Interactive Planner. For more information, refer to the Planning Switches Manual and the Interactive Planning Window via the Planning Control Module.

Vendor

The system code for the service/part provider. This field is populated when maintenance is performed by an outside vendor. (This is commonly used for major maintenance such as a C-Check).

Note: This information comes from the Vendor Master.

![]() Note: If the vendor field is populated then Switch

Note: If the vendor field is populated then Switch ![]() WOTCESIGN will not function correctly. For more information, refer to the Production Switches Manual.

WOTCESIGN will not function correctly. For more information, refer to the Production Switches Manual.

COSL

The Component Operating Storage Limits for the Work Order. This field is informational only.

AMP/MS

The Aircraft Maintenance Program/Maintenance Schedule for the Work Order. This field is informational only. When Switch ![]() AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab. For additional information, refer to the Production Switches Manual. This field will be mandatory when Switch

AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab. For additional information, refer to the Production Switches Manual. This field will be mandatory when Switch ![]() MANDATAMP is set to Yes. For additional information, refer to the Production Switches Manual.

MANDATAMP is set to Yes. For additional information, refer to the Production Switches Manual.

Revision

The Revision number of the physical manual being used for this A/C Type/Series. When Switch ![]() AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab. For additional information, refer to the Production Switches Manual. This field will be mandatory when Switch

AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab. For additional information, refer to the Production Switches Manual. This field will be mandatory when Switch ![]() MANDATAMP is set to Yes. For additional information, refer to the Production Switches Manual.

MANDATAMP is set to Yes. For additional information, refer to the Production Switches Manual.

Date

The Date the manual was last revised. When Switch ![]() AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab. For additional information, refer to the Production Switches Manual. This field will be mandatory when Switch

AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab. For additional information, refer to the Production Switches Manual. This field will be mandatory when Switch ![]() MANDATAMP is set to Yes. For additional information, refer to the Production Switches Manual.

MANDATAMP is set to Yes. For additional information, refer to the Production Switches Manual.

TR

The Temporary Revision number of the physical manual being used for this Type/Series. When Switch ![]() AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab.

AUTOPAMP is set to Yes, the information in this field will be auto populated from the AMP field in A/C Type/Series, General tab.

Import section

Customer W/O - The Work Order number of the customer for third party maintenance.

Import Parts and Tools ![]() button - Select this button to import parts and tools. For additional information, refer to the Import Parts and Tools Button via Work Order Buttons which can be found in the Production Training manual.

button - Select this button to import parts and tools. For additional information, refer to the Import Parts and Tools Button via Work Order Buttons which can be found in the Production Training manual.

Import W/O N/R Task Card ![]() button - Select this button to import customer Non-Routine Task Cards. For additional information refer to the Import W/O N/R Task Card Button via Work Order Buttons which can be found in the Production Training manual.

button - Select this button to import customer Non-Routine Task Cards. For additional information refer to the Import W/O N/R Task Card Button via Work Order Buttons which can be found in the Production Training manual.

Note: This import option is only used for Third Party Work Orders. The Third Party Checkbox must be checked for this option to be available.

Import W/O Task Card ![]() button - Select this button to import customer Task Cards. For additional information refer to the Import W/O Task Card Button via Work Order Buttons which can be found in the Production Training manual.

button - Select this button to import customer Task Cards. For additional information refer to the Import W/O Task Card Button via Work Order Buttons which can be found in the Production Training manual.

Note: This import option is only used for Third Party Work Orders. The Third Party Checkbox must be selected for this option to be available.

![]() The Import W/O Task Card button is security controlled via Security Explorer/ Production/ Update/ W/O. For more information refer to the Security Explorer via the System Administration Training Manual.

The Import W/O Task Card button is security controlled via Security Explorer/ Production/ Update/ W/O. For more information refer to the Security Explorer via the System Administration Training Manual.

Import W/O Task Card Express ![]() button - The Import Work Order Task Card Express button allows the user to import Task Cards that already exist in the system onto the Work Order. The only column in the import file is 'Task Card' and as long as the Task Card exists in the system, when the file is imported all the Task Card details will populate onto the work order. For more information refer to the Import W/O Task Card Express Button.

button - The Import Work Order Task Card Express button allows the user to import Task Cards that already exist in the system onto the Work Order. The only column in the import file is 'Task Card' and as long as the Task Card exists in the system, when the file is imported all the Task Card details will populate onto the work order. For more information refer to the Import W/O Task Card Express Button.

![]() This button is security controlled via Production/ Update/ W/O/ W/O Task Card Express Import. For more information refer to the Security Explorer of the System Administration module.

This button is security controlled via Production/ Update/ W/O/ W/O Task Card Express Import. For more information refer to the Security Explorer of the System Administration module.

Note: This import option is only used for Third Party Work Orders. The Third Party checkbox must be checked for this option to be available.

Note: This option is part of customer-specific functionality, and is therefore not available for most operators.

Import W/O E/C ![]() button - The Import W/O E/C option is used to quickly import Engineering Controls that already exist in the system into a Work Order for the creation of a W/O package. The TPW (Third-Part Work) checkbox must be selected in the General tab in order for this button to appear. Fore more information refer to the Import W/O E/C Button.

button - The Import W/O E/C option is used to quickly import Engineering Controls that already exist in the system into a Work Order for the creation of a W/O package. The TPW (Third-Part Work) checkbox must be selected in the General tab in order for this button to appear. Fore more information refer to the Import W/O E/C Button.

![]() This button is security controlled via Production/ Update/ W/O/ W/O E/C Import. For more information refer to the Security Explorer of the System Administration module.

This button is security controlled via Production/ Update/ W/O/ W/O E/C Import. For more information refer to the Security Explorer of the System Administration module.

Note: This import option is only used for Third Party Work Orders. The Third Party checkbox must be checked for this option to be available.

Close Vendor Task Cards ![]() button

button ![]() - The Close Vendor Task Cards Import button allows users to import a list of Task Cards completed by a Vendor. These Task Cards and their linked E/Cs must already be linked to the W/O, but they will be automatically closed in the system once the import is completed. For more information refer to the Close Vendor Task Cards Button.

- The Close Vendor Task Cards Import button allows users to import a list of Task Cards completed by a Vendor. These Task Cards and their linked E/Cs must already be linked to the W/O, but they will be automatically closed in the system once the import is completed. For more information refer to the Close Vendor Task Cards Button.

Note: A Vendor must be populated in the Vendor field (above) in order for this button to be available in this window.

Import Work Order Task Card From History ![]() button - Select this button to import Work Order Task Cards from the history of the Work Order. For additional information, refer to the Import Work Order Task Card From History Button via Work Order Header which can be found in the Production Training Manual.

button - Select this button to import Work Order Task Cards from the history of the Work Order. For additional information, refer to the Import Work Order Task Card From History Button via Work Order Header which can be found in the Production Training Manual.

Note: This button only appears in the Work Order Detail, Optional tab for Third Party Work Orders.

![]() The Import W/O Task Card From History button is security controlled via Security Explorer/ Production/ Update/ W/O. For more information refer to the Security Explorer via the System Administration Training Manual.

The Import W/O Task Card From History button is security controlled via Security Explorer/ Production/ Update/ W/O. For more information refer to the Security Explorer via the System Administration Training Manual.

Link E/C with T/C ![]() button

button ![]() - Select this button to link T/Cs and E/Cs that have been added to the same W/O. This button will not function if the T/C and/or E/C is not already added to the W/O. For additional information, refer to Link E/C with T/C button via Work Order Detail, Optional Tab.

- Select this button to link T/Cs and E/Cs that have been added to the same W/O. This button will not function if the T/C and/or E/C is not already added to the W/O. For additional information, refer to Link E/C with T/C button via Work Order Detail, Optional Tab.

_____________________________________________________________________________________

Share

Share

Print

Print