Share

Share

Print

Print

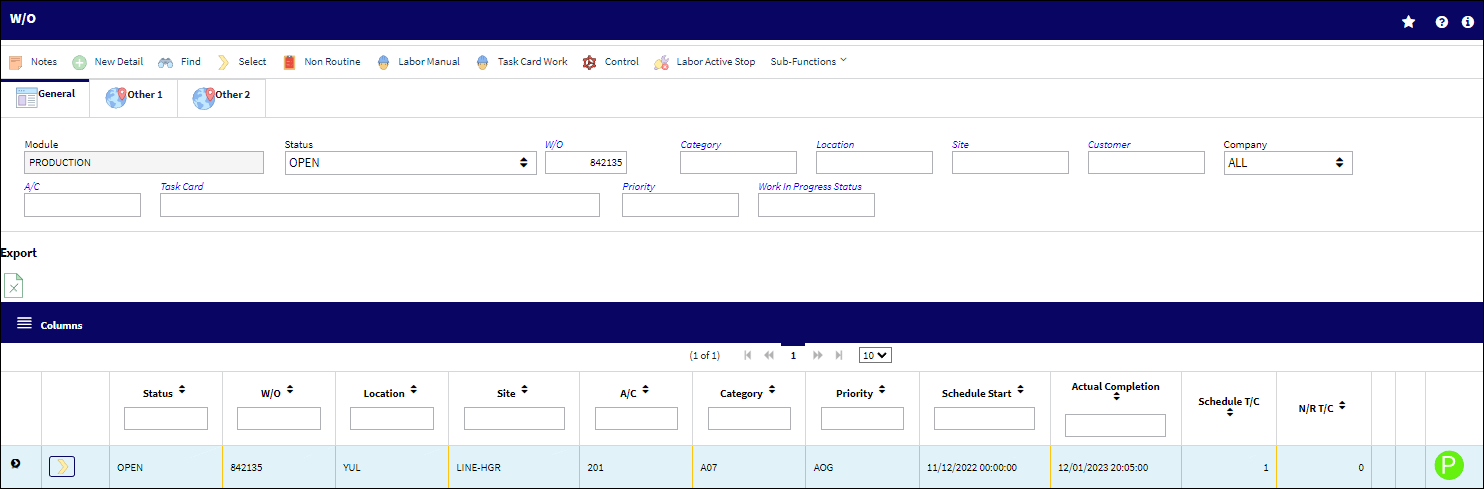

Work Order, General Tab

The Work Order, General Tab is used to query for Work Orders based on the following search criteria. The user may also select the New ![]() button to create a new Work Order from this window, or the Select

button to create a new Work Order from this window, or the Select ![]() button to view and modify the details of the selected Work Order.

button to view and modify the details of the selected Work Order.

Enter any of the below search criteria to query for a desired Work Order and select the Find ![]() button.

button.

Query:

_____________________________________________________________________________________

Module

Indicates the module that the user is working in. Defaults to PRODUCTION in this window.

Status drop down

The current Status of the Work Order (e.g., Open, Completed, Closed, etc). The following options are available:

All - When selected, the query results will not be filtered by W/O status.

Open - The Work Order has been created and authorized (if applicable). The W/O is available for users to action tasks, track man hours, and issue parts while accomplishing tasks attached to the W/O.

Note: If a part is issued to a W/O and later returned to stock (RTS) while the W/O is Open, the system will force the user to RTS Credit W/O, which may not be the desired transaction.

Completed - Once all Task Cards attached to the W/O are actioned (closed, deferred, canceled) the W/O status automatically changes from Open to Completed. At this point the W/O is completed but not closed, updates are allowed.

Closed - Work Order is closed, no updates allowed. The Closed status indicates that the W/O Actuals are finalized and the financials are closed. Unused materials cannot be returned to stock to credit the W/O.

Note: When Production Switch ![]() PCWOFBR is set to Yes, a W/O's status cannot be changed from Closed to any other status, even if the user has security access to 'W/O Re-Open' (above). When set to No, a W/O can be changed from Closed status (as long as they have the above security access to 'W/O Re-Open'). For detailed information refer to Switch

PCWOFBR is set to Yes, a W/O's status cannot be changed from Closed to any other status, even if the user has security access to 'W/O Re-Open' (above). When set to No, a W/O can be changed from Closed status (as long as they have the above security access to 'W/O Re-Open'). For detailed information refer to Switch ![]() PCWOFBR via the Production Switches Manual.

PCWOFBR via the Production Switches Manual.

![]() Note: The Work Order can be re-opened with security access. This field is security-controlled via Production/ Update/ W/O/ W/O Re-Open. For more information refer to the Security Explorer via the System Administration Training Manual.

Note: The Work Order can be re-opened with security access. This field is security-controlled via Production/ Update/ W/O/ W/O Re-Open. For more information refer to the Security Explorer via the System Administration Training Manual.

Hold - Work Order is on Hold, no updates allowed, but not closed.

Line - Work Order is for Line Maintenance Issues only (items returned will not require Credit Work Order). Because it is necessary for material to be issued to a Work Order on the system, some companies prefer to use specific Work Order's for this purpose. A Work Order could be created for every aircraft turn around but this may cause an unacceptable administrative burden. For the purposes of creating W/O's with material requirements, it is possible to select the Line status rather than Open status (when creating the new Work Order). The Line status will allow rotable parts to be issued to the Work Order and later returned U/S (if removed at a later time). For additional information, please refer to the Work Order closing section regarding closing Line Work Orders.

Generation - Work Order is in the process of being created and tasks are being attached. No technician or Mechanic will be able to log on to a Task Card until the status is changed to Open.

Note: Planners create Work Order's with the status Generation. Upon completing the Work Order package, the planner should change the status to Open.

Post Completed - When the Post Completed status is set, compliance records are written for E/Cs, P/N E/Cs, P/N Controls, and defects, their repeat schedules reset, and unused material can be returned to stock (RTS) to credit the W/O. This status takes place before the W/O is officially closed.

Note: Parts that were issued to the Work Order can be returned to stock even after the W/O is in Closed status. For more information refer to the Batch in Inventory Audit (via the Return to Stock button) in the Inventory Training Manual.

Note: Production Switch ![]() WOPOSTCM must be set to Yes.

WOPOSTCM must be set to Yes.

Pre/Auth - Work Order has not yet been authorized through the W/O Authorization Explorer.

W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

![]() Warning: It is important to set Customer Orders Switch

Warning: It is important to set Customer Orders Switch ![]() CUST/ORD at a much higher configuration number than the configuration number of Production Switch

CUST/ORD at a much higher configuration number than the configuration number of Production Switch ![]() WOSEQ to avoid Sales Orders and Work Orders from ever having the same order number. This will prevent inventoried parts from being misallocated.

WOSEQ to avoid Sales Orders and Work Orders from ever having the same order number. This will prevent inventoried parts from being misallocated.

Category

Work Order Category code.

Note: In the Interactive Planner, the W/O Category can allow for graphical color assignment by category.

Location

The Location for maintenance events, inventory stores, orders, transactions, or training events.

Site

The Site where the work should be carried out (if applicable).

Customer

The customer for whom the Work Order was created.

Note: This field is also available on the Work Order, Other 1 tab. If the Customer field is populated in the Work Order, General tab, the system will not allow the user to utilize this field in the Work Order, Other 1 tab.

Company

The company the Work Order was created for.

Note: For more information, refer to the Multi Company Functionality.

A/C

The individual aircraft tail number.

Task Card

The Task Card / Job Card that details the scheduled maintenance work. Users can search for all Work Orders linked to a particular Task Card.

Priority

The priority of the Work Order (e.g., Urgent).

Work In Progress Status

Select a System Transaction Code to query by. This field is informational only and used for the purpose of querying for specific Work Orders.

_____________________________________________________________________________________

Results:

_____________________________________________________________________________________

Status

The status of the Work Order.

W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

Location

The Location for maintenance events, inventory stores, orders, transactions, or training events.

Site

The Site where the work should be carried out (if applicable).

A/C

The individual aircraft tail number.

Category

Work Order Category code.

Note: In the Interactive Planner, the W/O Category can allow for graphical color assignment by category.

Priority

The priority of the W/O (i.e. Urgent).

Schedule Start ![]()

Sort/filter W/O search results by the scheduled start date or the actual date the work began.

Actual Completion ![]()

Sort/filter W/O search results by the actual date the work was completed.

Schedule T/C

The Task Card / Job Card that details the scheduled maintenance work.

N/R T/C

The Non-Routine Task Card that details non-scheduled maintenance work / findings.

Defect ![]()

The number of defects associated with the W/O.

Note: This field is only available when switch ![]() TCDEFINFO is set to Yes. For more information, refer to Task Control Switches.

TCDEFINFO is set to Yes. For more information, refer to Task Control Switches.

Reservation Status Indicator ![]() button

button

The display of the Reservation Status Indicator ![]() button allows planners to see when a part(s) has been reserved (all/partial/none).

button allows planners to see when a part(s) has been reserved (all/partial/none).

Red Reservation Status Indicator ![]() - Indicates that a part that is required to complete the W/O has not yet been reserved.

- Indicates that a part that is required to complete the W/O has not yet been reserved.

Green Reservation Status Indicator ![]() - Indicates that all part requirements for the W/O have been reserved.

- Indicates that all part requirements for the W/O have been reserved.

Yellow Reservation Status Indicator ![]() - Indicates that the part requirements for the W/O have only partially been reserved.

- Indicates that the part requirements for the W/O have only partially been reserved.

Blue Reservation Status Indicator ![]() - Indicates that more material was added to the W/O after the previous requirements had been reserved.

- Indicates that more material was added to the W/O after the previous requirements had been reserved.

Part Location Indicator ![]() button

button

The display of the Part Location Indicator button allows planners to see when a part(s) that is needed to complete the W/O is available (all/partial/none) at the W/O's location.

Red Part Location Indicator ![]() - Indicates that the part(s) required to complete the W/O is not available at the W/O's location.

- Indicates that the part(s) required to complete the W/O is not available at the W/O's location.

Yellow Reservation Status Indicator ![]() - Indicates that only some of the parts required to complete the W/O are available at the W/O's location.

- Indicates that only some of the parts required to complete the W/O are available at the W/O's location.

Green Reservation Status Indicator ![]() - Indicates that all parts required to complete the W/O are available at the W/O's location.

- Indicates that all parts required to complete the W/O are available at the W/O's location.

Tool Status Indicator ![]() button

button

The display of the Tool Status Indicator button allows planners to see when a tool(s) has been reserved (all/partial/none).

Red Tool Status Indicator ![]() - Indicates that a tool that is required to complete the W/O has not yet been reserved.

- Indicates that a tool that is required to complete the W/O has not yet been reserved.

Yellow Tool Status Indicator ![]() - Indicates that the tool requirements for the W/O have only partially been reserved.

- Indicates that the tool requirements for the W/O have only partially been reserved.

Green Tool Status Indicator ![]() - Indicates that all tool requirements for the W/O have been reserved.

- Indicates that all tool requirements for the W/O have been reserved.

Schedule

The scheduled start and completion date/time for implementing the Work Order.

Note: The schedule fields may be automatically modified depending on the Category selected. For detailed information, refer to the W/O Config ![]() button in the W/O Category via the Production Transaction Code Manual.

button in the W/O Category via the Production Transaction Code Manual.

Schedule Start Date - The date/time that the work is scheduled to begin. The Start Date does not affect whether the Work Order may be deleted or not. However, if the work has been started, the Work Order may not be deleted.

Schedule Completion Date - The date/time that the work is scheduled to be completed. This time field is defaulted to 23:59 upon creation of the W/O.

Actual

The actual start and completion date/time for implementing the Work Order.

Actual Start Date - The date that the W/O is actually started. This may differ from the previously scheduled date. If work has been started, this date cannot be deleted. The Start Date does not affect whether the Work Order may be deleted or not. If Work Order has been started, it cannot be deleted.

Actual Completion Date - The date that the W/O is actually completed. This date may differ from the previously scheduled date. This date will be the same as the scheduled date when the W/O is created but will be automatically overridden when the W/O is closed. This time field is defaulted to 23:59 upon creation of the W/O.

N/R T/C Today

The number of Non-Routine Task Cards created and attached on the current date.

Customer

The customer for whom the Work Order was created.

Customer P.O.

For Third Party purchase, if purchase is on behalf of a customer the PO number may be entered here. Additional Use - if a Sales Order is generated in the system for the service requirement, it may cross reference here as well. This is to be defined by the company procedures. This does not invoice or charge the customer for any service provided. It is only used as a reference number. Users can search for this field through the Work Order, Other 2 tab.

TAT

Turn Around Time for the contract. This field is only applicable for Third Party W/Os and is assigned through the associated Production Customer Contract.

TAT Date

The Time After Turnaround Date. This field is only applicable for Third Party W/Os and is assigned through the associated Production Customer Contract.

Created By

The user who created the record.

Parent W/O

If this Work Order acts as a “child” to a parent Work Order, that parent Work Order should appear here. For more information on how to create parent/child Work Order relationships, please refer to Change The Parent Work Order button.

Description

The description of the Work Order.

Completion Date

The date/time that the work is scheduled to be completed.

T/C Completion %

The total percentage of Task Cards that have been completed against the Work Order.

Man Hours Reserved %

This is the total of reserved man hours (per man) to carry out the work. Formula = Man Hours x Men Required.

W/O Time Used %

The elapsed hours of the time taken to complete the work. (i.e. If a Work Order is scheduled for 6 days and was completed in 36 Man Hours, the W/O Time Used will equal 50%, because it only took 3 days to complete the work.)

Work In Progress Status

A user defined System Transaction Code which describes the status of the Work In Progress. Users must have security to have access to this System Transaction Code. For security to this Transaction Code, go to Security Explorer/Settings/Explorer/Work In Progress Status.

Note: When this Status is set to 'WIP' (work in progress), the Status of the W/O automatically goes from 'Generation' to 'Open' once the window is saved. This functionality only happens if the W/O's Category transaction code has the 'Activate the Time Fields for WIP' checkbox selected. This checkbox is available through the Config W/O button in the transaction code. For more information refer to the W/O Category via the Production Transaction Code Manual. Further, this functionality is only applicable when the W/O Status is Generation. In order for this option to be available, Switch ![]() WOSTATGEN must be set to Yes. For more information refer to the Production Switches Manual.

WOSTATGEN must be set to Yes. For more information refer to the Production Switches Manual.

_____________________________________________________________________________________

The Export as Excel ![]() button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

The Columns ![]() button is used to select which columns will appear in the the window's search results/table section. For more information, refer to Columns Button via the eMRO System Standards manual.

button is used to select which columns will appear in the the window's search results/table section. For more information, refer to Columns Button via the eMRO System Standards manual.

The Filter/Sort ![]() button is used to alter the search criteria for records associated with the host module and window. For more information, refer to Filter/Sort Button via the eMRO System Standards Module.

button is used to alter the search criteria for records associated with the host module and window. For more information, refer to Filter/Sort Button via the eMRO System Standards Module.

Share

Share

Print

Print