Share

Share

Print

Print

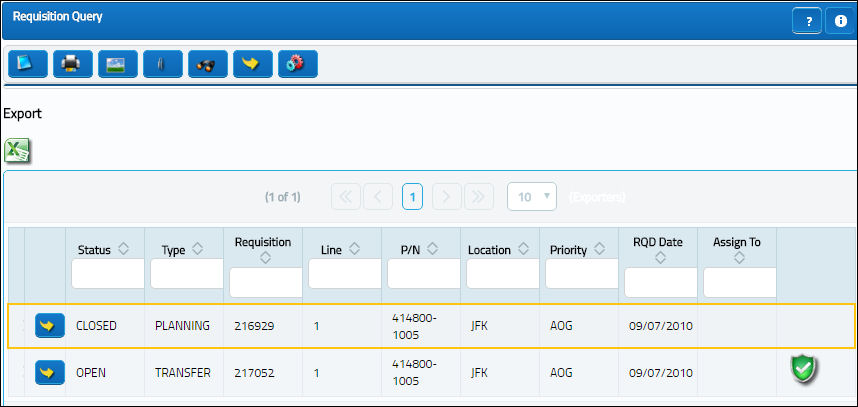

Select the Requisitions ![]() button to view and access any Requisition(s) associated to the W/O, as needed. For more information on how to create a requisition, please refer to the Requisition Training Manual.

button to view and access any Requisition(s) associated to the W/O, as needed. For more information on how to create a requisition, please refer to the Requisition Training Manual.

The following information/options are available in this window:

_____________________________________________________________________________________

Status

The current status of the Requisition line item.

Open - By default all newly created requisition items will have a status of ‘Open’ until attached to an order.

Ordered - Once the Requisition is attached to an open Order the Status will go to 'Ordered.'

Closed - Once the requisitioned item is received the Status will change to 'Closed.'

Canceled - This Status may only be achieved by requisition authorization rejection or Requisition Management Cancellation.

Type

The type of Requisition used to identify the purpose of the request. The requisition type is also useful for sort, filters and searches in the system. A default requisition type may be configured. These are defined in the Requisition Type System Transaction Code.

Requisition

List of required parts for either a maintenance item or for restocking.

Note: The system configuration Switch ![]() REQSEQ (Config Number field) assigns this number to the created requisition.

REQSEQ (Config Number field) assigns this number to the created requisition.

Location

The required delivery location.

Note: The Inventory flag must be selected in the Location Master for this transaction to be applicable.

Priority

Identify the urgency of the request or requisition. Additionally, notification based on the requisition priority may be defined by location. These codes are defined in the Priority System Transaction Codes.

Note: Expedite days and priority level are defined in the Priority Transaction Code.

A/C

The individual aircraft tail number.

W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

ATA

The Air Transport Association Chapter, Section and Paragraph numbers associated to the Requisition.

Assigned To

The employee (buyer) that this Requisition is assigned to. This can only be edited on ‘Open’ Requisitions. This field is auto populated with the value that appears via Settings/ Update/ P/N/ Inventory Levels button/ General Tab/ Buyer field. The Assign To Buyer will be populated if the part has been previously set up with an assigned buyer. An assigned buyer is defined via Settings/ Update/ P/N/ Inventory Levels button/ General Tab/ Buyer field.

RQD Date

The date that the item(s) is/are required by.

Created By

The user who created the record.

P/N Maintenance

The part number maintenance number.

P/N Description

The description of the part.

RQRD QTY

The quantity of items/parts required.

ORD QTY

The number of parts for the transaction.

RCVD QTY

The quantity of parts that were received.

UOM

The unit of measure. This will default if associated with a Part Number as defined in the P/N Master. Transactions for parts can be conducted in a different UOM than defined in the P/N Master. However, upon receiving the UOM, conversion will automatically adjust the quantities, providing that the conversion rate is defined in the UOM System Transaction Code (via Setting/Explorer/System Transaction Code).

Preferred Vendor

The preferred vendor to acquire the parts from (if applicable).

Planner

The person responsible for material planning for this part.

_____________________________________________________________________________________

The Export as Excel ![]() button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

The following buttons are available to offer additional functionality:

Share

Share

Print

Print