Share

Share

Print

Print

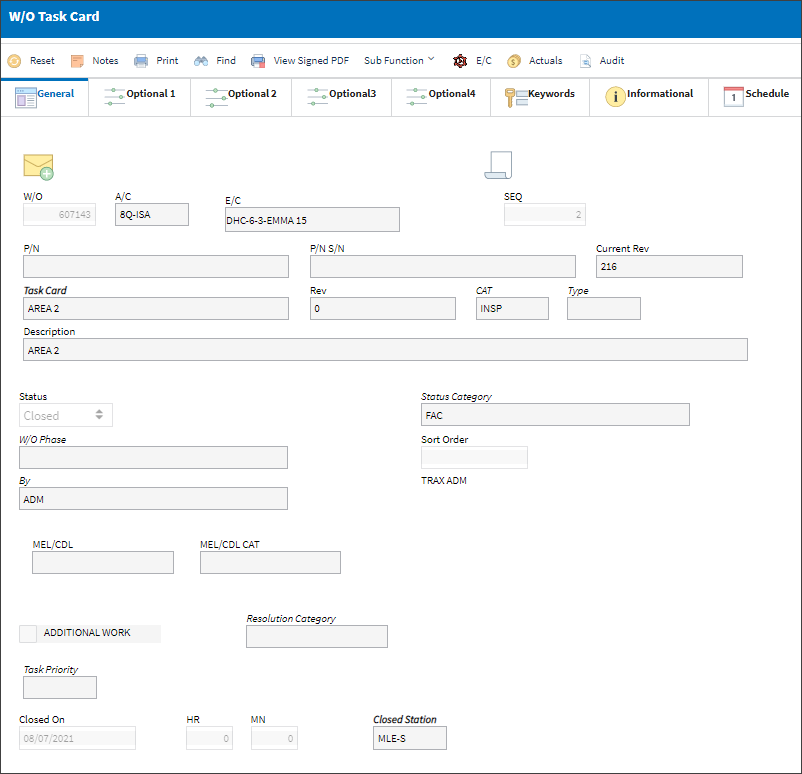

Once a Task Card is selected from the W/O Task Card header window, the W/O Task Card, General tab appears as follows. This window shows the details of the Task Card linked to the Work Order. If adding a new T/C to the W/O after the New ![]() button was selected in the previous window, enter the T/C to be linked to the Work Order in the Task Card field.

button was selected in the previous window, enter the T/C to be linked to the Work Order in the Task Card field.

Note: When switch ![]() TCEFFECT is set to Yes, only Task Cards that are effective to the W/O Aircraft can be saved against the Work Order. When set to No, non-effective Task Cards can be saved against the Work Order. For more information refer to Production switch

TCEFFECT is set to Yes, only Task Cards that are effective to the W/O Aircraft can be saved against the Work Order. When set to No, non-effective Task Cards can be saved against the Work Order. For more information refer to Production switch ![]() TCEFFECT via the Production Switches Manual.

TCEFFECT via the Production Switches Manual.

The following information/options are available in this window:

_____________________________________________________________________________________

Paper Copy Required ![]() icon

icon

This button indicates that information related to this Work Order Task Card / Non-Routine Task Card has been printed and must be processed. For additional information, refer to the Task Card, Optional 2 Tab via the Task Card section of the Engineering - T/C Training Manual.

W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

A/C

The individual aircraft tail number.

E/C

The Engineering Control that specifies aircraft or component scheduled maintenance intervals.

Link EC to Task Card ![]() button

button ![]()

This button allows users to modify the Engineering Control that this Task Card is linked to. Users will only be allowed to link the T/C to an E/C that is currently linked to the Work Order. Once an E/C is selected, the E/C field to the left of this button will contain the selected E/C.

SEQ ![]()

The Sequence Number. This number is generated from the number of times the Work Order (or Shop Work Order) Pack Print is printed and/or when the Sequence/Resequence buttons are selected through the Work Pack Print>Task Card button. (I.e., if there are ten Task Cards on a Work Order, and the Work Order has been printed twice from the Work Order Pack Print, for the first occurrence of the Work Order Pack Print, the Task Card would have a SEQ of one. For the second occurrence, the Task Card would have a SEQ number of 11.)

P/N

The Part Number reference for the aircraft part. This part is effective to the E/C that the scheduled Task Card is associated to, and is currently installed on the W/O's Aircraft.

P/N S/N

The Serial Number for the specific serialized part. This part is effective to the E/C that the scheduled Task Card is associated to, and is currently installed on the W/O's Aircraft.

Current Rev ![]()

The Task Card's most recent authorized revision number.

Note: This field displays the last authorized revision of the Task Card. If the Task Card attached to the Work Order (Rev field) is not the latest revision, the user may link the last authorized revision to the W/O.

Parent E/C

The Parent Engineering Control associated with the E/C. This parent E/C is specified in the E/C which contains the schedule. When the Parent is selected, it will bring in all dependent E/Cs (Child E/Cs) on to the Work Order as required. For more information, please refer to the Engineering Control, Schedule Tab via the Engineering - E/C Training manual.

Task Card

The Task Card / Job Card that details the scheduled maintenance work.

Note: When switch ![]() TCEFFECT is set to Yes, only Task Cards that are effective to the W/O Aircraft can be saved against the Work Order. When set to No, non-effective Task Cards can be saved against the Work Order. For more information refer to Production switch

TCEFFECT is set to Yes, only Task Cards that are effective to the W/O Aircraft can be saved against the Work Order. When set to No, non-effective Task Cards can be saved against the Work Order. For more information refer to Production switch ![]() TCEFFECT via the Production Switches Manual.

TCEFFECT via the Production Switches Manual.

![]() Note: When the Task Card field's pop-up selection window is opened, only Task Cards that are effective to the W/O Aircraft and that are in 'Open' Status will be displayed.

Note: When the Task Card field's pop-up selection window is opened, only Task Cards that are effective to the W/O Aircraft and that are in 'Open' Status will be displayed.

Rev

The revision number of the Task Card when it was attached to the Work Order.

Note: This revision may or may not be the latest authorized revision of the Task Card. Compare with Current Rev field, which displays the last authorized revision from Engineering.

CAT

The Task Card's Category, as defined in Task Card Category transaction code via the Engineering Transaction Codes. Task Card Authorization Steps are defined in System Transaction Codes by Task Card Category.

Type

The Task Card Type, as defined in the Transaction Code. This code can be used to sort and locate Task Cards.

Description

The description of the Task Card.

Note: For Panel Open and Close Task Cards, the description of the Task Card will always default to the one defined using the Production Switches ![]() PNLTCOPEN and PNLTCCLOSE.

PNLTCOPEN and PNLTCCLOSE.

Status

The Status of the Task Card. Any Task Cards with Cancel status will not be printed on a Work Order. For more information on each available status, please refer to the field description inside Task Card Work Button, via Work Order.

Note: Task Cards cannot be re-Opened once the associated W/O Engineering Control has been reset. However, Non-Routine Task Cards can be re-opened if the W/O E/C has been reset.

Status Category

The sub-status of the card (hold/defer reason). (Linked from the T/C Optional tab.)

W/O Phase

The particular phase of the work flow that this particular card pertains to.

Sort Order

The sort order (printing sequence) of this Task Card / Non-Routine.

By

The employee who worked on the Task Card and therefore triggered one of the following statuses:

- Open

- Cancel

- Closed

- Defer

- Delayed

- Hold

- On Condition

Note: Even if the By field is greyed out, even if the Task Card has been printed, the user can update the By field by adjusting the status of the Task Card in the W/O Task Card window. The employee who last worked on the Task Card, or modified it will be reflected/updated in the W/O Task Card, General tab. For additional information, refer to the Task Card Work Button, via the Work Order Buttons of the Production Training Manual. This also applies to Shop Task Cards.

MEL/CDL

The MEL/CDL field allows the user to enter the MEL or CDL reference related to the deferral. MEL/CDL may be defined, entered or digitally imported in the MEL Master. For additional information, refer to the MEL Master via the Settings Training Manual.

MEL/CDL CAT

Minimum Equipment List Category that is defined in the associated Defect Report. The MEL number and the MEL category can be associated to one another via the MEL Master. This field is only informational.

Additional Work checkbox

This informational checkbox is selected when the invoiced Task Card (Routine or Non-Routine) was designated as additional work. For this to appear, the Task Card must have the Additional Work checkbox selected. For more information refer to the W/O Task Card, Optional 2 Tab via the Task Card Button of the Production Training Manual.

Task Priority

The priority level of the Task Card.

Open On

The date the Task Card was opened for the W/O.

Open Station

The Station associated with the W/O Task Card opening. Only stations marked as maintenance locations are accepted.

_____________________________________________________________________________________

The Export as Excel ![]() button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

button can be selected to view the queried data (including all pages) in an Excel spreadsheet. This Excel file can be saved for later use. For more information refer to the Export as Excel Button via the eMRO System Standards manual.

Task Cards may automatically get attached to W/Os through selected E/Cs that call on the T/Cs. For more information, refer to E/C Button, via Work Order Detail.

Note: Any Task Cards that were previously attached will be copied over, so they can be changed without affecting the original (i.e. The user may wish to write a specific note on the card for the Mechanics/Technicians that does not normally appear).

Share

Share

Print

Print