Share

Share

Print

Print

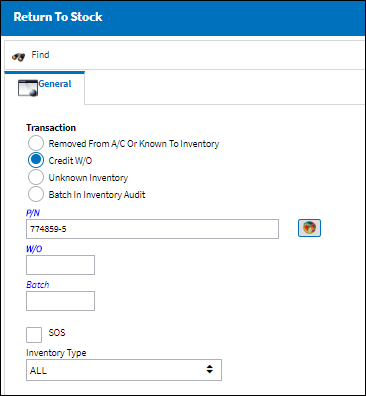

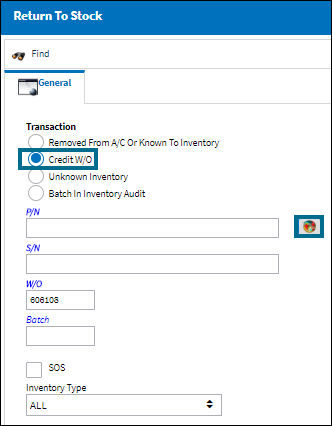

From Inventory Transaction, select the Return to Stock ![]() button after first entering the appropriate Part Number. The 'Credit W/O' options is used when returning a part to stock that was previously issued to a W/O, but was not used by the time the W/O was closed. Once the 'Credit W/O' option is selected, enter the Work Order that the part was issued to. Completing the Return to Stock Process with this Transaction will affect the finances related to the specified Work Order.

button after first entering the appropriate Part Number. The 'Credit W/O' options is used when returning a part to stock that was previously issued to a W/O, but was not used by the time the W/O was closed. Once the 'Credit W/O' option is selected, enter the Work Order that the part was issued to. Completing the Return to Stock Process with this Transaction will affect the finances related to the specified Work Order.

The following information/options are available in this window:

_____________________________________________________________________________________

Credit W/O radio button

Select this radio button to return a part to stock which was issued to a Work Order but not used. Completing the process with this transaction will affect the finances related to the specified Work Order.

_____________________________________________________________________________________

Select the Find ![]() button.

button.

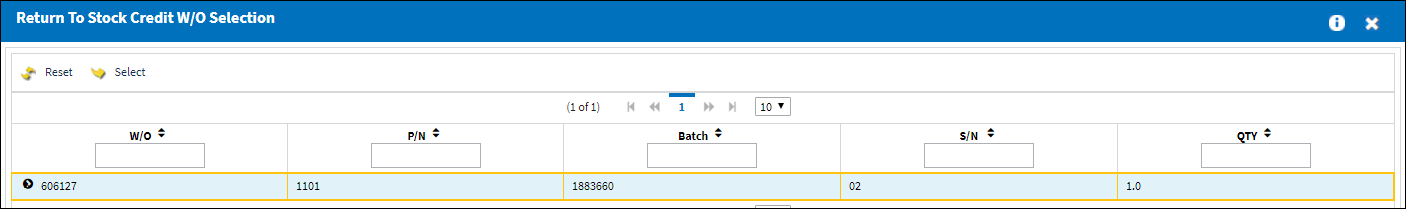

The system then displays items that are being returned to stock that were issued to a Work Order and not used. Select the exact batch or serial number that was issued and click the Select ![]() button.

button.

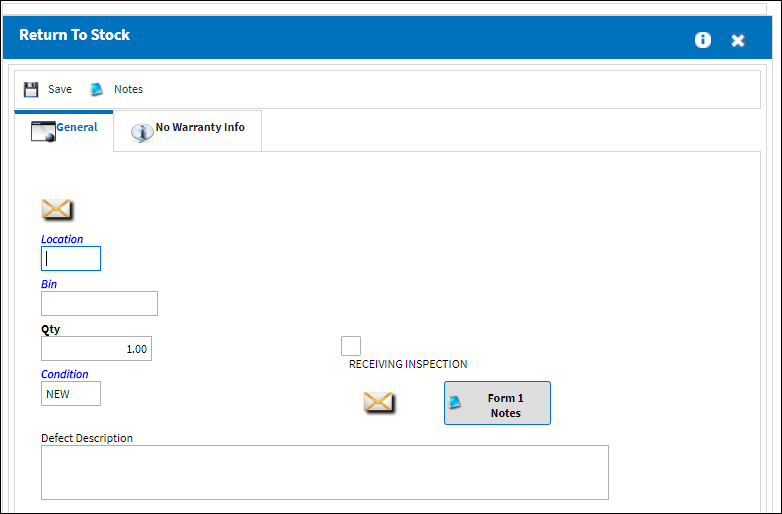

The system displays the Return to Stock detail window.

The following information/options are available in this window:

_____________________________________________________________________________________

Location

The Location for maintenance events, inventory stores, orders, transactions, or training events.

Note: If a quarantine location is entered, the system will request an unserviceable (U/S) code for the item. This will move the item quantity into the Unserviceable field.

Bin

The specific storage bin within the inventory location.

Auto Populate Bin ![]() button

button

Select this button to auto populate the bin for this part. The bin must be set up against the part in the P/N Master. For additional information, refer to the Bin Category field, via the P/N Master, Optional Tab of the Settings Training Manual.

Qty

The quantity of part(s) being returned to stock.

Receiving Inspection checkbox

Check to indicate that Receiving Inspection is required for the part.

U/S Code

Unserviceable code if part is to be stored in Quarantine location. This field is only available, in lieu of the Receiving Inspection checkbox, upon selecting a Location that has been designated as Quarantine in the Location Master, General tab.

U/S NO

An Unserviceable Number that is used to help identify U/S parts without a serial number (i.e. Repairables). This is informational only and is only available, in lieu of the Receiving Inspection checkbox, upon selecting a Location that has been designated as Quarantine in the Location Master, General tab.

Condition

The condition of the part.

Defect Description

The description of the Defect related to the part that was removed from the aircraft. This text will be automatically copied to any Repair Order that is created for the part. The information will be placed in the Defect field of the Removal and Removal History Tabs.

Hazardous Material ![]() icon

icon

This icon appears if the part contains hazardous materials. For additional information, refer to the P/N Master, Inventory Tab via P/N Master of the Settings Training Manual.

Form 1 Notes ![]() button

button

Select to add a note to be added in the Remarks section of the Form 1 for the part.

_____________________________________________________________________________________

Select the Save ![]() button to save all information. The system produces a tag which can be printed if required.

button to save all information. The system produces a tag which can be printed if required.

The part will now show on the Inventory Transaction window as available (if serviceable), unserviceable, or in Receiving Inspection depending on the data entered. The Work Order will be credited for the items that were returned and relevant financial adjustments made.

Auto Update Credit W/O to Batch In Inventory Audit:

The system can now automatically override the Credit W/O transaction with the Batch In Inventory Audit transaction.

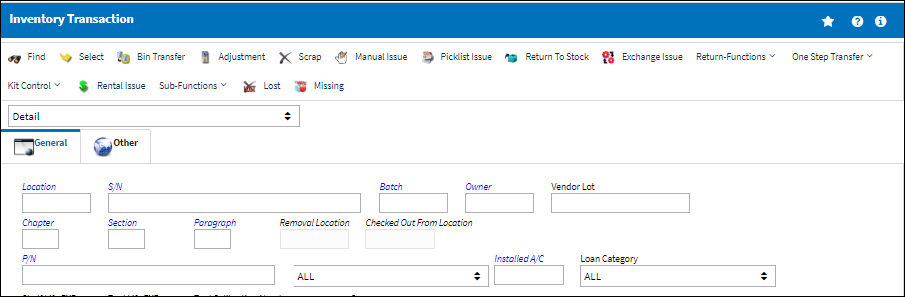

From Inventory Transaction, return the following part to stock.

Select the RTN Stock ![]() button.

button.

From the Return To Stock window, select the Credit W/O radio button to return the unused part to stock.

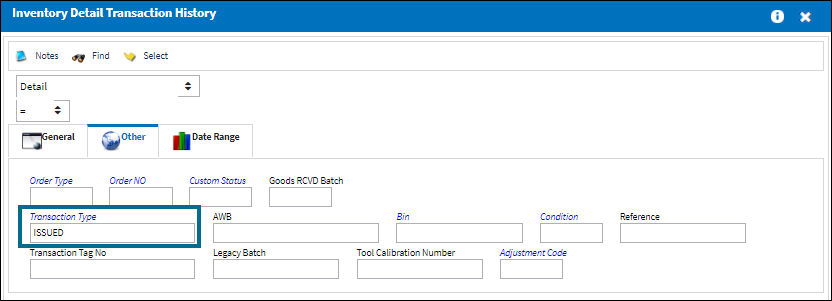

Select the Inventory Detail Transaction History ![]() button to look up the batch number for the part.

button to look up the batch number for the part.

The Inventory Detail Transaction History window appears. Notice that the system has updated the transaction to the correct RTS transaction type 'Batch In Inventory Audit' because the part has a transaction history. Double select the highlighted section from the Inventory Detail Transaction History window.

The Batch number is auto populated and the user may continue with the Return to Stock 'Batch In Inventory Audit' transaction.

Share

Share

Print

Print