Share

Share

Print

Print

The Corrosion/Damage & Repair window deals with the aircraft's Corrosion/Damage & Repair (CDR) which is part of the maintenance program, especially in cases of aging aircraft. It is often treated as a separate aspect of aircraft maintenance. A baseline program is published in the manufacturer's document for every airplane model. As an operator, you may adopt the program in total or develop CDRs tailored to your particular operation.

![]() This button is security-controlled via Technical Records/ Update/ Defect Report/ Corrosion, Damage and Repair. For additional information, refer to the Security Explorer via the System Administration Training Manual.

This button is security-controlled via Technical Records/ Update/ Defect Report/ Corrosion, Damage and Repair. For additional information, refer to the Security Explorer via the System Administration Training Manual.

CDR tasks are mainly structural inspections and often require extensive work to allow access to the inspection area. The area is cleaned and inspected - if required with non-destructive inspection. If necessary, any corrosion or damage is repaired. Prior to close access, the area is treated with corrosion protection compounds.

However, during the day to day operations, technicians may also identify CDR and associate their findings to the Defect Report when the problem is located.

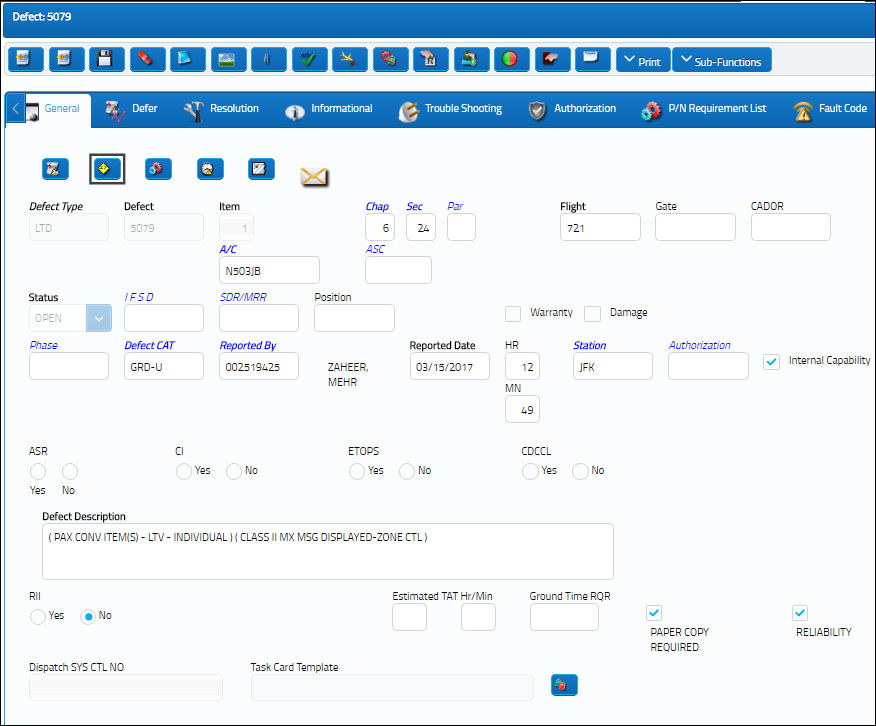

From the Defect Report Detail, General tab, select the Corrosion/Damage & Repair ![]() button.

button.

The system displays the Corrosion Damage Repair window:

The following information/options are available in this window:

_____________________________________________________________________________________

CPCP (Corrosion Prevention/Corrosion Protection) Task/Structural Inspection Yes/No radio button

Select the Yes radio button if the Task Card generating the Non-Routine is a CPCP Task or a structural Inspection. Select No if the Task Card generating the Non-Routine is not a CPCP Task or a structural Inspection.

Authorized to Close checkbox

Indicates that the Corrosion/Damage has been resolved and that the Defect Report or Non-Routine Task Card can be Resolved/Closed. If Corrosion/Damage is reported but this checkbox is not selected, users are not able to close to Defect Report or the Non-Routine Task Card.

Cause

The reason/cause of the damage.

Previously Blended Yes/No radio button

Select the Yes radio button if the area had a previously blended repair. Select No if the area has not had a previously blended repair.

Replacement/Reinforcement Required Yes/No radio button

Select 'Yes' if any parts had to be replaced or reinforced during the repair. Select 'No' if no parts had to be replaced or reinforced during the repair.

Note: If 'Yes' is selected, the Part Number field becomes mandatory for the save of the record.

Part Number - The Part Number reference for the aircraft part.

Corrosion Area

The area where the corrosion occurred.

Corrosion Level

The level of corrosion that occurred.

Engineering Employee

Engineering employee number. This identifies the engineer who authorized/confirmed the corrosion level.

Note: The Employee does not need to exist in the Employee Master.

Damage Type

The Damage Type Code. To view/set up these codes, go to Settings/ Explorer/ System Transaction Codes/ Technical Records/ Damage Type.

Structural Category

The Structural Category Code. To view/set up these codes, go to Settings/ Explorer/ System Transaction Codes/ Technical Records/ Structural Category.

Damage Description

Enter a brief description of the damages to the aircraft. This is a free text field and is informational only.

Inspector EMP #

Inspector employee number. This identifies the inspector who completed the CPCP.

Note: The Employee does not need to exist in the Employee Master.

_____________________________________________________________________________________

Dimensions:

_____________________________________________________________________________________

Length/Width/Depth

The dimension (length, width, depth) of the damaged area.

_____________________________________________________________________________________

Action Taken:

_____________________________________________________________________________________

In Limits Yes/No radio button

Select whether the corrosion is within allowable limits.

Acc (According)

Enter a reference document that the work was completed according to. (e.g. SRN 53-00-0)

Blend Repair Yes/No radio button

Select the Yes radio button if there was any blending done to the repair. Select No if no blending was done to the repair.

Note: If the 'Yes' radio button is selected, the Original Material Thickness, Blend Out Length, Width and Remaining Thickness fields all become mandatory for the save of the record.

Original Material Thickness

The original thickness of the material before blending.

Blend Out Length

The length of the area the blending was done.

Width

The width of the area the blending was done.

Remaining Thickness

The remaining thickness of the blended area.

NDT Performed radio button

Non Destructive Testing. Select the 'Yes' radio button if NDT was performed, or the 'No' radio button is NDT was not performed.

Repair Performed radio button

Select the Yes radio button if a repair was performed. Select No if a repair was not performed.

Work Performed

Enter the work performed for the aircraft. This is a free text field.

Repair Category

The Repair Category Code. To view/set up these codes, go to Settings/ Explorer/ System Transaction Codes/ Technical Records/ Repair Category.

P/N Damage Part

The part number of the damaged part.

S/N Damage Part

The serial number of the damaged part.

_____________________________________________________________________________________

Location of Damage:

_____________________________________________________________________________________

Section - To Section

The section covering the damage area.

Station - To Station

The station of the aircraft. This is a physical location on the aircraft in inches from a datum point.

Stringer - To Stringer

In aircraft construction, a Stringer (also known as Longeron) is a thin strip of wood or metal, to which the skin of the aircraft is fastened.

Water Line - To Water Line

A horizontal line through the center of the aircraft in its flying position. Water lines are drawn parallel to one another in three to six inch intervals. This is a range between two numbers.

Buttock Line - To Buttock Line

Lines that are determined by looking at the plan view of the aircraft. A centerline of the aircraft is established and labeled 'buttock line 0.' This is a range between two numbers.

Plus

Enter any additional information regarding the station. This is a free text field and is informational only.

_____________________________________________________________________________________

Share

Share

Print

Print