Share

Share

Print

Print

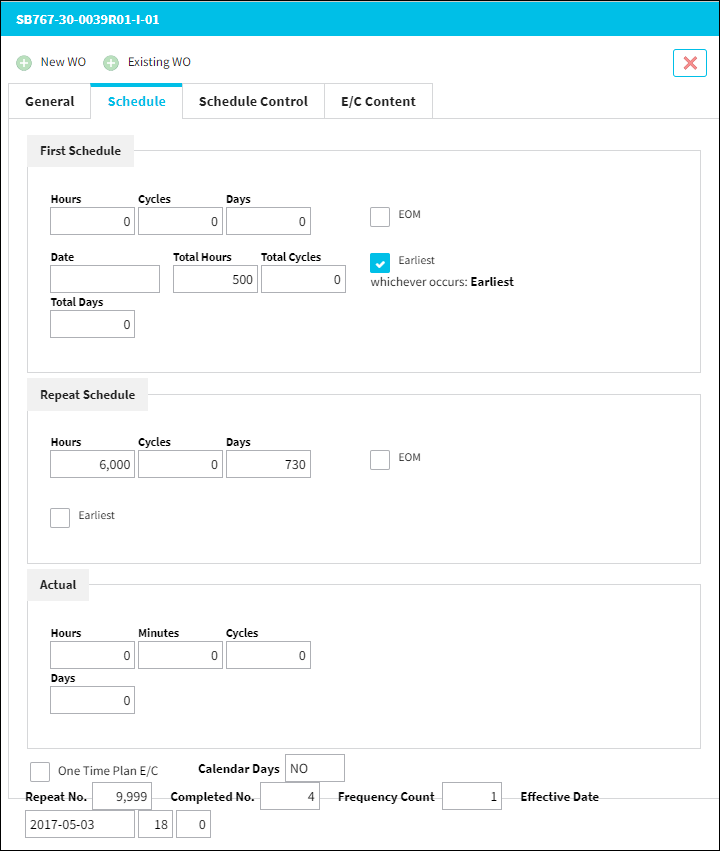

Schedule Tab, via E/C Detail

The Schedule tab allows the user to view th schedule (or time limits) for the E/C. This tab is informational only.

The following information/options are available in this window:

_____________________________________________________________________________________

Effective Date

Entered as the date from which the user requires to track time on the E/C being set up unless a Total Schedule has been defined. Once the effective date is entered and the A/C or P/N Effectivity for the E/C is applied, changing the effective date on this Tab will not change the effective dates on each individual aircraft or component that the E/C is effective to. Either the Effectivity will need to be removed and re-applied, or the effective date field will need to be changed individually in the Effectivity Override window for each tail number or component.

Note: If the effective date is greater than the current date, planning will not forecast for this E/C until the effective date has been met.

Repeat Number

The number of occasions the E/C will be repeated. If the Repeat Number is set to 1, the E/C is a one time only E/C and only the First Schedule is applicable. If the Repeat Number is set to 9999, the E/C will be carried out on the First Schedule 1 time and then the Repeat Schedule indefinitely. If the Repeat Number is a specific number, such as 5, the E/C will be carried out on the First Schedule 1 time and then be repeated 4 times according to the parameters configured on the Repeat Schedule (and then terminated).

First Schedule section

Hours/Cycles/Days - The First Schedule is the parameter and threshold for the initial occurrence and compliance of the E/C, as some E/Cs may have multiple schedules. The First Schedule only takes effect if there is no previous compliance against the E/C. The Effective Date based schedule is the initial Schedule Hours/Cycles/Days threshold parameter for this E/C. The hours/cycles/days are being calculated based on the effective date of the E/C. The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unchecked, then it will be the latest occurrence.

Total Schedule (Total Hours/Total Cycles/Total Days) - The Total Hours/Cycles/Days are calculated based on whatever the E/C is effective to. If the E/C is effective to an aircraft, the Totals will be based on the Total Hours/Cycles/Days of the aircraft. If the E/C is effective to a component, the Totals will be based on the Total Hours/Cycles/Days of the component. The Total Schedule works for both A/C E/Cs and P/N E/Cs and a mixed Schedule can be utilized between the Effective Date Based Schedule and the Total Schedule. For E/Cs created with a Total Days schedule, the planning is driven by the Manufacturer Date, via A/C Master, Other 1 tab. However, if the Manufacturer Date is not populated, then Planning will be driven by the Service Date, via A/C Master, General tab.

Note: Planning Switch ![]() PN_EC_INSTDAYS and the Calendar Days field selection will determine whether a P/N E/C's Due Date is calculated based on the part's installed date or on the P/N E/C's Effective Date. For more information, refer to Switch

PN_EC_INSTDAYS and the Calendar Days field selection will determine whether a P/N E/C's Due Date is calculated based on the part's installed date or on the P/N E/C's Effective Date. For more information, refer to Switch ![]() PN_EC_INSTDAYS via the Planning Switches Manual.

PN_EC_INSTDAYS via the Planning Switches Manual.

First Schedule Date - The initial Schedule Date limit (due date) on this E/C. For example, an AD might have a NLT (No Later Than) Date for the First Schedule of the E/C.

Earliest checkbox - The Earliest checkbox option is selected if the E/C Schedule parameters are to be planned at the earliest occurrence. By selecting the Earliest checkbox, the schedule will be determined by which occurrence comes first: the Hours, Cycles, Days, or Date. For the latest occurrence, this checkbox should not be selected. This same logic is used independently by the parameters of the Effective Date-based Schedule (left) and of the Total Schedule (right).

Note: If a combination of the Schedule Hours, Schedule Cycles, Schedule Days, and Schedule Date fields are populated with a schedule, checking the Earliest checkbox will make the E/C become due at whichever schedule option comes due first.

Whichever Occurs - This dropdown field selection allows users to control which schedule option will be used between both the Effective Date-based Schedule (left) and the Total Schedule (right). Select the 'Earliest' dropdown option to have the system default to the schedule that reaches the earliest occurrence between the Hours/Cycles/Days/Date parameters (left) or the Total Hours/Total Cycles/Total Days parameters (right). Select the 'Latest' option to default to the schedule that reaches the latest occurrence between the two schedule types.

EOM checkbox - If the EOM checkbox is selected, the E/C will be due at the end of the month of the calculated due date (i.e. if an E/C is calculated to be due April 20, it will show up in Planning as due at the end of the month, i.e. April 30).

Repeat Schedule section

If the E/C has a Repeat Number greater than 1, then the Repeat Schedule is the parameter for the subsequent repetitive occurrences of the E/C for repeat compliance requirements. As with the First Schedule, some E/Cs may have multiple schedules. When an E/C has multiple schedules, the Earliest checkbox is pivotal in the configuration as the E/C may call for the compliance to be accomplished at the latest occurrence. The First Schedule information must be entered in order for the Repeat Schedule to be applicable.

Note: The First and Repeat Schedules are not meant to be utilized by Shop E/Cs.

Repeat Schedule Hours/Cycles/Days - The Repeat Schedule Hours/Cycles/Days threshold parameter for this E/C (If applicable). The system will default to the Earliest occurrence of these parameters, unless the Earliest flag is unchecked, then it will be the latest occurrence.

Repeat Schedule Date - The Repeat Schedule Date limit (due date) on this E/C. This is most common for an initial inspection and a follow up inspection.

Calendar Days

The Calendar Days drop down allows the user to determine how the E/C's due date will be calculated in the planning forecast:

- Yes - The planning forecast calculates the E/C's due date based on calendar days starting from the E/C's Effective Date (reset/last compliance date).

- No - The planning forecast calculates the E/C's due date based on calendar days starting from the P/N S/N installed date (if the P/N S/N's installed date is after the E/C's Effective Date). For P/N E/Cs Only.

No Fly - The planning forecast calculates the E/C's due date based on calendar days starting from the A/C last flight date or E/C last compliance date, whichever occurred most recently. For A/C E/Cs Only.

No Fly - The planning forecast calculates the E/C's due date based on calendar days starting from the A/C last flight date or E/C last compliance date, whichever occurred most recently. For A/C E/Cs Only.Note: The No Fly option is only available in eMRO v5 and later releases. In earlier releases, the Calendar Days field was a checkbox, providing only the Yes (selected) and No (unselected) option.

Total Frequency

Indicates how many frequencies (occurrences) the E/C is to be performed for one frequency cycle to be completed. This field works in conjunction with the frequency field in the Schedule Control (By) tabs, where the users specifies at which frequency child E/Cs should be called on.

Note: Using frequencies allows users to create simple and/or complex relationships between a parent E/C and its called on child E/Cs. Using frequencies eliminates the need to use the Next E/C field.

_____________________________________________________________________________________

Share

Share

Print

Print