Share

Share

Print

Print

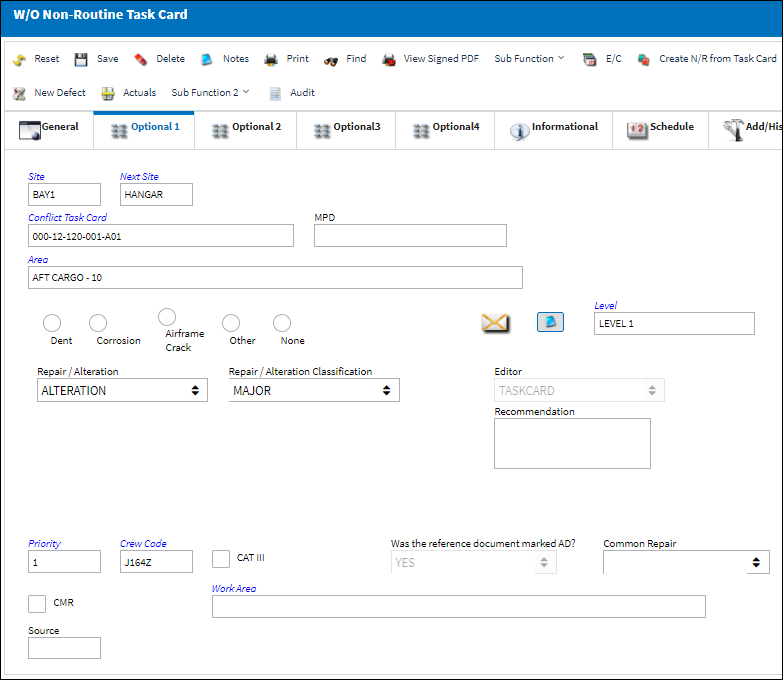

The W/O Non-Routine Task Card, Optional 1 tab allows the user to enter/update optional information related to a Non-Routine Task Card. This window is accessed from the Work Order Detail window via the Non-Routine Task Card ![]() button.

button.

The following information/options are available in this window:

_____________________________________________________________________________________

Site

The Site where the work should be carried out (if applicable).

Next Site

The Next Site where a component would be moved to upon completion.

Conflict Task Card

If a Task Card is specified here, it will indicate that the current Task Card should not be performed should it appear in a Work Order with the specified Task Card.

Note: If an Engineering Control with a Conflict Task Card is removed from a W/O then added back to that W/O, or if the E/C (with the Conflict T/C) is revised and re-authorized while linked to the W/O, the original Conflict Task Card will be removed from the work package.

MPD

The Maintenance Planning Document reference for this Non-Routine Task Card.

Area

The Area of the aircraft which this Non-Routine Task Card is related to, as defined in the Trans Code.

Damage radio buttons

Indicate the type of damage being addressed by the W/O Task Card. The options are as follows:

Dent radio button - Indicates that a dent was sustained to the body of the aircraft.

Corrosion radio button - This checkbox indicates that this is a Corrosion Card. When selected, the appropriately related field will appear on the Work Order. When selected, the Level field becomes mandatory.

Note: When the Corrosion checkbox is selected, the Corrosion Prevention and Protection tab becomes activated in the W/O Non-Routine Task Card window. For additional information, refer to the Non-Routine Task Card Button, Corrosion Prevention and Protection Tab, Via Non-Routine Task Card Button which can be found in the Production Training manual.

Note: The Corrosion/Damage & Repair ![]() button is available in the W/O Non-Routine Task Card, General tab upon selecting the Dent, Corrosion, Airframe Crack, or Other radio button.

button is available in the W/O Non-Routine Task Card, General tab upon selecting the Dent, Corrosion, Airframe Crack, or Other radio button.

Level - The level of corrosion noted from the inspection. This field is mandatory when the Corrosion checkbox is selected.

Airframe Crack radio button - Indicates that a crack was sustained to the airframe.

Other radio button - Indicates a type of damage sustained by the aircraft that is not a dent, corrosion or a crack.

None radio button - Indicates that no damage was sustained.

Repair/Alteration

Defines if the record requires Repair or Alteration.

Other - The component is neither altered or repaired. This is a miscellaneous option.

Alteration - This compliance of the Non-Routine Task Card will alter the component (i.e. the removal or addition of sub-components).

Repair - The compliance of the Non-Routine Task Card will repair the component (i.e. a structural component has sheet metal work completed to strengthen the integrity of the structure).

Repair / Alteration Classification - The level of Repair/Alteration (Major, Minor) required for this Non-Routine Task Card.

Editor

The Editor that will be used to edit Non-Routine Task Card information on an individual basis. If the Task Card is created manually the Editor will default to TASKCARD; if the Task Card is imported via TraxDocs the Editor will default to TRAXDOC – the default Editor can be changed in either cases before the record is saved.

TASKCARD – The TASKCARD Editor uses a mix of the Rich Text Format (RTF) stylesheet and TraxDoc to compose Task Card Items. This means that all Items for that Task Card, whether entered through RTF or brought in through TraxDoc loads, will be linked. RTF Items can also reference TraxDoc Items, if necessary.

Note: When printing the Task Card, the customer's custom datawindows can be set to look the same as their stylesheet Task Cards.

TRAXDOC - The TRAXDOC Editor uses uploaded Style Sheets in TRAXDOC as a template for the Task Card print; Task Cards for each TRAXDOC can have a different layout based on the criteria of the TRAXDOC Style Sheet (i.e. fleet type, customer). The TRAXDOC Editor is not a RTF Editor. When TRAXDOC Editor is selected, a TraxDoc No field appears to enter the TraxDoc reference number.

TraxDoc Number

Enter the TraxDoc number. This is a record number that is automatically generated within TraxDoc.

Note: This field appears when the 'TRAXDOC' Editor is selected.

TraxDoc ![]() button

button

Select the TraxDoc ![]() button. The TraxDoc Document window appears.

button. The TraxDoc Document window appears.

Recommendation

Allows lead mechanics or supervisors to provide recommendations to the mechanic(s) working on the W/O Non-Routine Task Card.

Priority

The priority of the Task Card (e.g., Normal, Urgent).

Crew Code

Any crew code associated with the Non-Routine Task Card.

CAT III checkbox

Indicates that the card is a Category III.

Was the Reference Document marked AD?

Users can indicate whether or not the reference document is related to an AD (Airworthiness Directive). The options are Yes or No.

Note: The drop down field will automatically default to 'Yes' if the associated Scheduled Task Card Category code is 'EA-AD, EO-AD or ROUTN-AD'. This field will default to 'No' if one of the specified Category codes is not selected. A user without permissions will not be able to change the defaulted values.

The above Category Codes can be defaulted by selecting the AD Category checkbox via the Task Card Category Transaction code. For additional information, refer to the Task Card Category Transaction code via the Engineering Transaction Code Manual.

![]() This field is security-controlled via Production/ Update/ W/O/ W/O Non Routine Express Reference Task Card field. For more information refer to the Security Explorer via the System Administration Training Manual.

This field is security-controlled via Production/ Update/ W/O/ W/O Non Routine Express Reference Task Card field. For more information refer to the Security Explorer via the System Administration Training Manual.

CMR checkbox

Certification Maintenance Requirement. This is required by the FAA in order to maintain certification of aircraft.

Work Area

Allows users to move Non-Routine Task Cards along with the progress of the check. This field is controlled via the Production System Transaction Code 'W/O Area.'

Common Repair drop down

Users can select from common repair procedures that are input via Production tran code 'Common Repair.'

_____________________________________________________________________________________

Share

Share

Print

Print