Share

Share

Print

Print

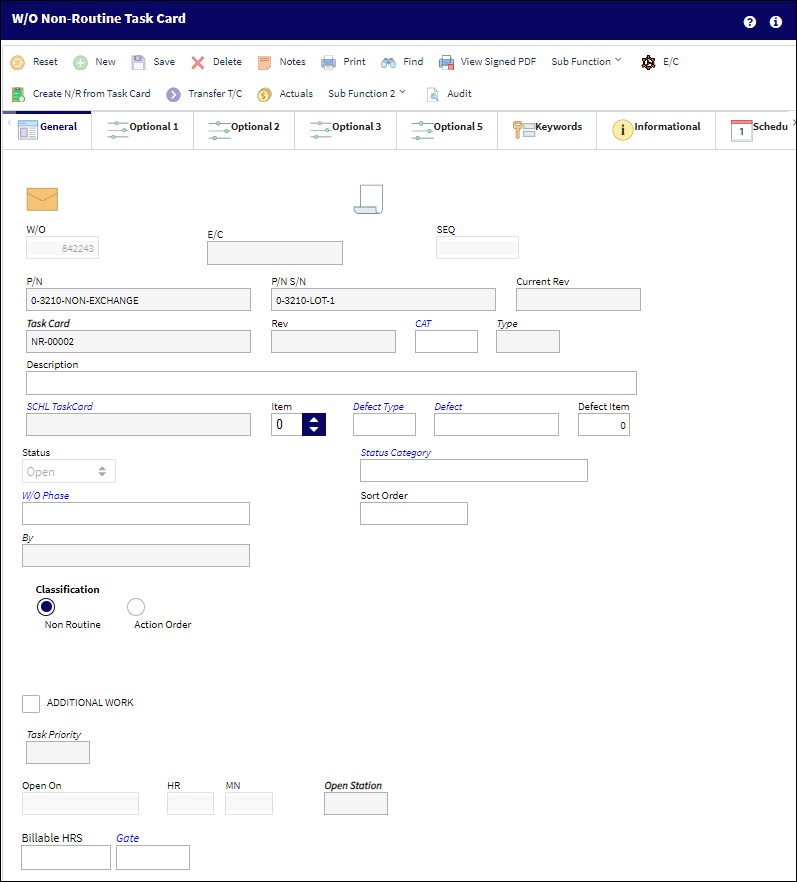

The W/O Non-Routine Task Card, General tab allows the user to attach a Non-Routine Task Card to a Shop Work Order. This window is accessed from the Shop Work Order window via the Non-Routine Task Card ![]() button.

button.

The following information/options are available in this window:

_____________________________________________________________________________________

W/O

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

A/C

The individual aircraft tail number.

E/C

The Engineering Control that specifies aircraft or component scheduled maintenance intervals.

Paper Copy Required ![]() button

button

This button indicates that information related to this Work Order Task Card / Non-Routine Task Card has been printed and must be processed. For additional information, refer to the Task Card, Optional 2 Tab via the Task Card section of the Engineering - T/C Training Manual.

P/N

The Part Number reference for the aircraft part.

P/N S/N

The Serial Number for the specific serialized part.

Material Necessary

Choose whether any material is necessary to complete the Task Card (Yes/ No). This is informational only.

Allow Edit Non Routine Data ![]() button

button

Select this button to open the fields in the Non-Routine Task Card to allow for edit.

Task Card

The Non-Routine Task Card that details non-scheduled maintenance work / findings.

Revision

The Task Card's most recent authorized revision number.

CAT

The Task Card's Category, as defined in Task Card Category transaction code via the Engineering Transaction Codes. Task Card Authorization Steps are defined in System Transaction Codes by Task Card Category.

Type

The Task Card Type, as defined in the Transaction Code. This code can be used to sort and locate Task Cards.

Description

The description of the Task Card.

Corrosion / Damage & Repair ![]() button

button

This button allows the user to view the Corrosion Damage and Repair window. This window deals with the aircraft's Corrosion/Damage & Repair which is part of the maintenance program, especially in cases of aging aircraft.

Note: This button is available upon selecting the Dent, Corrosion, Airframe Crack, or Other radio button in the W/O Non-Routine Task Card, Optional 1 tab. For additional information, refer to the Corrosion/Damage & Repair Button, via the Defect Report Detail, General Tab, via Defect Report of the Technical Records Training Manual.

SCHL Task Card

Allows for associating a scheduled or non-scheduled Task Card created via Engineering/ Update/ Task Card and associate it to the Non-Routine Task Card. This can also be used to specify a Task Card that triggered the Non-Routine Task Card.

Note: This field is no longer mandatory when creating Non-Routine Task Cards for Third Party Work Orders.

Note: Either the SCHL Task Card or the Defect field is mandatory with Switch ![]() WONRSCHDEF set to Yes.

WONRSCHDEF set to Yes.

Defect

The Defect Report associated with the Non-Routine Task Card. Once the defect associated to the Non-Routine Task Card has been completed, the Non-Routine Task Card will be closed and the Work Order will be completed.

Note: This field is no longer mandatory when creating Non-Routine Task Cards for Third Party Work Orders.

Note: Either the SCHL Task Card or the Defect field is mandatory with Switch ![]() WONRSCHDEF set to Yes.

WONRSCHDEF set to Yes.

Defect ![]() button

button

Select the Defect ![]() button to create a new defect to link to the Non-Routine Task Card. The Defer Task Card Transfer To Defect Reports window will appear allowing the user to create a new defect from the W/O Non-Routine Task Card window.

button to create a new defect to link to the Non-Routine Task Card. The Defer Task Card Transfer To Defect Reports window will appear allowing the user to create a new defect from the W/O Non-Routine Task Card window.

Allow Edit Data ![]() button

button

Select this button to be able to edit the status of the Task Card.

Status

The current status of the Non-Routine Task Card. The status of the N/R Task Card is helpful in determining the stage the Task Card is at with regard to it's completion. Ultimately, the completion of the Task Cards will result in the closing of the Work Order.

Status Category

The sub-status of the card (hold/defer reason).

Work Order Phase

The particular phase of the work flow that this particular card pertains to.

Sort Order

The sort order (printing sequence) of this Task Card / Non-Routine.

Schedule Start Date/Time

The scheduled start date and time.

By

The employee who worked on the Non Routine Task Card and therefore triggered one of the following status':

- Open

- Cancel

- Closed

- Defer

- Delayed

- Hold

- On Condition

WONRPROD - When set to Yes, the Open On, Hour/Minute, By, and Open Station fields become mandatory in the in the Work Order Non Routine Task Card Window in the Productions module when the user tries to save a Work Order Non Routine Task Card. When set to No, the Open On, Hour/Minute, and Open Station fields in Work Order Non Routine Task Card are no longer mandatory.

WONRPROD - When set to Yes, the Open On, Hour/Minute, By, and Open Station fields become mandatory in the in the Work Order Non Routine Task Card Window in the Productions module when the user tries to save a Work Order Non Routine Task Card. When set to No, the Open On, Hour/Minute, and Open Station fields in Work Order Non Routine Task Card are no longer mandatory.Note: Even if the By field is greyed out, even if the Non Routine Task Card has been printed, the user can update the By field by adjusting the status of the Non Routine Task Card in the W/O Task Card window. The employee who last worked on the Non Routine Task Card, or modified it will be reflected/updated in the W/O Non Routine Task Card, General tab. For additional information, refer to the Task Card Work Button, via the Work Order Buttons of the Production Training Manual. This also applies to Shop Non Routine Task Cards.

Addition Work checkbox

This informational checkbox is selected when the invoiced Task Card (Routine or Non-Routine) was designated as additional work. For this to appear, the Task Card must have the Additional Work checkbox selected. For this to appear, the Task Card must have the Additional Work checkbox selected. For more information refer to the W/O Task Card, Optional 2 Tab via the Task Card Button of the Production Training Manual.

Cador

Civil Aviation Discrepancy Occurrence Report. This is a number that is generated by Transport Canada and assigned to track IRs (Incident Reports) and SDRs (Service Difficulty Reports) that are reported.

Warranty checkbox

This is checked if the Work Order is associated with a warranty condition. This is informational only.

Damage checkbox

This is checked if the Work Order is associated with a damaged condition. This is informational only.

Open On

The date that the Non-Routine Task Card was opened.

Time

The scheduled start time.

Scheduled End Date/Time

The scheduled end date and time.

Task Priority

The priority level of the Task Card.

Classification (Non-Routine or Action Order)

Choose from Non-Routine or Action Order classification. The Action Order selection was created for a customer requesting custom programming.

Open Station

The station opening the Non-Routine Task Card.

Quotation Number

The Quotation Number for the Non-Routine Task Card. This information is entered manually and is informational only.

Due At A/C Hours

The Aircraft Hours that the item is due at.

Due At A/C Cycles

The Aircraft Cycles that the item is due at.

Due Date

The calculated due date of the item (rounded to the nearest date).

Billable HRS

The relevant billable man hours tied to the contract.

Gate

Specifies the gate at which the Task Card in question is designated to be performed.

_____________________________________________________________________________________

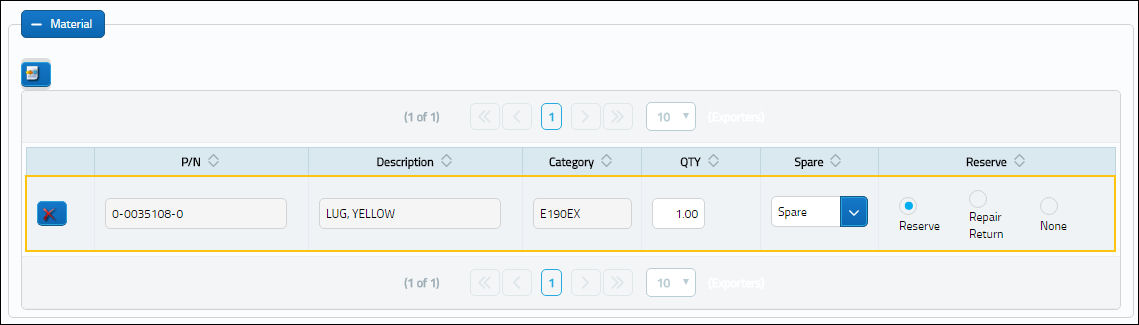

Materials:

Users can add or remove the parts required for the Non-Routine Task Card from the Materials section.

The following information/options are available in this window:

_____________________________________________________________________________________

Expand ![]() / Collapse

/ Collapse ![]() buttons

buttons

The Expand button displays all of the information for the section. The Collapse button hides the same information.

Add/Delete Record ![]() button

button

Select this button to add or remove parts that are associated to the Non-Routine Task Card. When selected, the Task Card P/N window pops up. The same fields in that window are also available in the Materials Section. From this window, however, users are able to set up System Notifications for the specific Task Card P/N by selecting the Notification ![]() button.

button.

New Record ![]() button

button

Select this button to add a new line item to the section.

Delete Record ![]() button

button

Delete the selected line item entry.

P/N

The Part Number reference for the aircraft part. This is the Part Number required for the N/R T/C. A part number may be specified only one time per Item Number. However, the same part number may be specified on each unique item number if needed. Users can select into this field or select the Add/Delete Record ![]() button to add a P/N.

button to add a P/N.

Description

The description of the part.

Item

The specific item number on the Non-Routine Task Card that this record is to be associated with. Leave default '0' to have this record associated with all item numbers on the Non-Routine Task Card.

Category

The category of the part as defined in Settings/ Explorer/ System Transaction Code Explorer/ Settings/ P/N Category (e.g. Rotable, Consumable, Repairable) and entered for the particular part in the P/N Master.

QTY

The quantity of items/parts required.

Spare/Tool drop down

Select Spare if the item required is a spare; this can be either an Expendable or a Rotable part. Select Tool if the item required is a tool; the P/N must be configured as a Tool in P/N Master via Settings/Update/P/N Master.

Reserve radio button

Select this button to reserve the spare or tool when W/O P/N reservation is applied. When a Picklist Reservation is made via a Work Order, only parts that have the Reserve radio button checked will be reserved. For more information regarding picklist creation, please go to Production/Update/Work Order/Picklist _ button.

Repair Return radio button

Select this button to repair/return the spare when W/O P/N reservation is applied. When a Picklist Repair/Return is made via a Work Order, only parts that have the Repair/Return radio button checked will be repaired or returned.

None radio button

Select this button if no spare or tool has been reserved or repaired.

_____________________________________________________________________________________

For more information on the options available in this section, refer to the P/N Button from the Engineering - T/C Training Manual.

Note: If the 'Allow N/R Creation' checkbox is deselected via the Work Order Header, Optional tab, users will be prevented from creating a Non-Routine Task Card for the W/O.

Share

Share

Print

Print