Share

Share

Print

Print

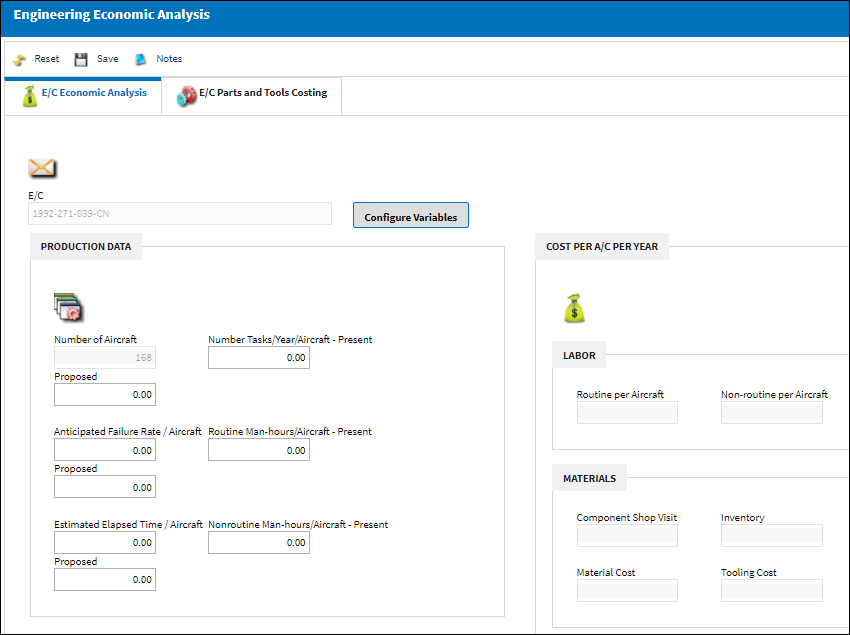

The E/C Economic Analysis tab contains the following information to help the operator assess the financial implications associated to the Engineering Control.

Note: Depending on the customized prints available to a company, the information presented in this tab may be available through various prints/reports.

The following information/options are available in this window:

_____________________________________________________________________________________

Production Data section

Number of Aircraft - The total number of aircraft referenced in the effectivity section of the E/C.

Number Tasks/Year/Aircraft - Present - If this is a new EC, this field is zero. For revised or deleted E/Cs, enter the number of tasks per year per aircraft proposed in the previous revision.

Number Tasks/Year/Aircraft Proposed - For E/Cs deleting a task, enter zero. In other cases, enter the expectation for the number of times the task will be accomplished.

Anticipated Failure Rate/Aircraft - The originator shall fill in the "decimal equivalent" of the percentage probability (i.e. enter .5 for 50%) that each time the routine task is accomplished, work of a non-routine nature will need to be accomplished as well.

Routine Man-hours/Aircraft - Present - If this is a new EC, this field is zero. For revised or deleted E/Cs, enter the number of man hours per aircraft proposed in the previous revision.

Routine Man-hours/Aircraft - Proposed - For E/Cs deleting a task, enter zero. In other cases, enter the expectation for the number of man hours per aircraft that can be expected. This number should contain input from the Base, Line or Component Production representative as appropriate to the task.

Estimated Elapsed Time/Aircraft - The originator will provide a number, which reflects, as a best estimate, the actual elapsed time to complete the task. This number is subject to factors such as skill level, working environment and the number of workers that, from a practical standpoint, can be assigned to accomplish the task.

Non Routine Man-hours/Aircraft - Present - If this is a new EC, this field is zero. For revised or deleted E/Cs, enter the number of non-routine man hours per aircraft proposed in the previous revision.

Non Routine Man-hours/Aircraft - Proposed - For E/Cs deleting a task, enter zero. In other cases, enter the expectation for the number of non-routine man hours per aircraft that can be expected. This number should contain input from the Base, Line or Component Production representative as appropriate to the task.

Cost/Reliability Analysis section

Total cost - This field is the sum of the values listed in the COST PER A/C PER YEAR section of this window.

Total benefit - This field is the sum of all the values listed in the IMPROVEMENT PER AIRCRAFT PER YEAR columns.

$net per A/C - The difference between the TOTAL COST and the TOTAL BENEFIT.

Writeups per Year - Present - The number of write-ups per year that the EC attempts to reduce or eliminate.

Writeups per Year - Estimate following task implement - The estimated number of write-ups that will still occur after implementation of the repetitive maintenance task.

Writeups per Year - Improvement - Improvement calculation that is based on the difference between the present estimate and the anticipated future values/savings following task implementation.

Writeups per Year - $ Improvement per aircraft - This calculation multiplies (write-up improvement X $50)/divided by the number of aircraft.

Delays per Year - Present - This is a list of the number of delays to the subject aircraft system that this E/C will attempt to reduce or eliminate.

Delays per Year - Estimate following task implement - The estimated number of delays per year that will still occur after implementation of the repetitive maintenance task.

Delays per Year - Improvement - Same as above.

Delays per Year - $ Improvement per aircraft - Same as above.

Delay Minutes per Year - Present - The current number of delay minutes per year on the subject aircraft system that the EC attempts to reduce or eliminate.

Delay Minutes per Year - Estimate following task implement - The estimated number of delays minutes per year that will still occur after implementation of the repetitive maintenance task.

Delay Minutes per Year - Improvement - Same as above.

Delay Minutes per Year - $ Improvement per aircraft - This is (Delay improvement*FLT SPEC DLYCALC)/number of aircraft.

Cancellations per Year - Present - The number of cancelations per year that the E/C attempts to reduce or eliminate.

Cancellations per Year - Estimate following task implement - The estimated number of cancelations per year that will still occur after implementation of the repetitive maintenance task.

Cancellations per Year - Improvement - Same as above.

Cancellations per Year - $ Improvement per aircraft - This is calculated by multiplying (FS=20, $XX, FS=30, $XX, FS=40, $XX, FS=50, $XX, FS=60, $XX, FS=70, $XX, FS=82, $XX, FS=90, $XX, FS=95, $XX, X cancellation improvement)/ divided by the number of aircraft.

Cycle Time Sensitive - Select 'Yes' if the task has a significant impact on the production cycle time for the visits that it will be included with.

Select 'No' if the task does not have a significant impact on the production cycle time for the visits that it will be included with.

The originator should obtain this information from discussions with Production about the way the task will be accomplished and how it fits into the visit scope.

Passenger Sensitive - Select 'Yes' if the task will address a passenger sensitive issue for the airline.

Select 'No' if the task will not address a passenger sensitive issue for the airline.

Line Sensitive - Select 'Yes' if the defined frequency is a line check or the if EQ/EC monitoring is required. Otherwise, select 'No'.

Note: If Line Sensitivity is 'Yes', an additional 25% will be added to the man-hour rate to provide a heavy-heavy bias.

Cost Per A/C Per Year: Labor section

Routine per Aircraft - Routine Man-hours per Aircraft * Current Labor Rate*Number of tasks/year/aircraft proposed)

Note: Labor Rate must be modifiable by an administrator. This value changes annually.

Non Routine per Aircraft - (Non-routine Man-hours per Aircraft * Current Labor Rate*Anticipated Failure Rate*Number of tasks/year/aircraft proposed)

Cost Per A/C: Materials

Component Shop Visit - The EC Part/Tools tab provides the information to calculate the following formula:

Part Quantity per EC x Part Shop Cost x Removal Rate x Number of tasks per year per Aircraft = Shop Cost per Aircraft for each part.

This formula must be applied to each part and the sum of all parts is the COMPONENT SHOP VISIT COST PER AIRCRAFT PER YEAR.

Note: This is for Overhaul & Make Serviceable Dispositions only.

Inventory - The E/C Part/Tools tab provides the information to calculate the following formula:

Spares x Cost/Part New / Number of Aircraft.

This formula must be applied to each part and the sum of all parts is the INVENTORY COST PER AIRCRAFT PER YEAR.

Note: This is for Scrap, Overhaul & Make Serviceable Dispositions.

Material Cost - The EC Part/Tools tab provides the information to calculate the following formula:

Part Quantity per EC x Part Cost New x Removal Rate x Number of Tasks per Year per Aircraft.

This formula must be applied to each part and the sum of all parts is the MATERIAL COST PER AIRCRAFT PER YEAR.

Note: This is for Scrap Disposition only.

Tooling Cost - The E/C Part/Tools tab provides the information to calculate the following formula:

Tool Quantity per aircraft x Tool Cost New/Number of Aircraft/5.

This formula must be applied to each tool and the sum of all tools is the TOOLING COST PER AIRCRAFT PER YEAR.

Informational:

Created By - The user who created the record.

Created Date - The date the record was created.

Modified By - The user who last modified the record.

Modified Date - The date the record was last modified.

_____________________________________________________________________________________

Share

Share

Print

Print