Share

Share

Print

Print

A part can be used in multiple service applications throughout its life (i.e. installed on different aircraft types/series, or in different assemblies) and therefore it will have different life limits (i.e. P/N Controls) for each of its service applications. These parts are set-up as prorated parts in the P/N Master.

Note: If a prorated limit schedule for an A/C Type/Series is lower than the P/N Control's default schedule, a part that has accumulated flight times that exceed that A/C lower limit while installed on an aircraft with a greater limit, may be overdue when installed on the A/C with the lower limit. Therefore that part would be considered overflown for the lower limited A/C. (For example: the P/N Control's default is 4,000 hours, and the part was installed on a 5,000 hours prorated A/C. On the 5,000 hours A/C, the part flew 3,700 hours. If the part is removed and installed on an A/C that has a 3,500 hours prorated limit schedule, the part will be considered overflown for that aircraft.)

A prorated calculation of the life consumed (i.e. sum of the fractions of accrued life) during the part's previous service applications is used to determine the remaining life in its current service application.

The prorated calculation is used only in the planning module and only for a part that is currently in service on an aircraft. It is not used for parts that are in the inventory.

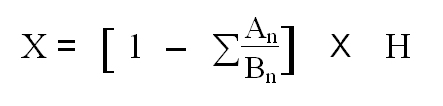

The prorated calculation is done automatically by the eMRO System using the following formula:

Where:

X = life remaining for the current service application.

åAn/Bn = sum of the fractions of accrued life from service applications.

A = time accrued in service application (n)

B = life limit in service application (n)

H = life limit for current service application.

Share

Share

Print

Print