Share

Share

Print

Print

The Prorated ![]() button allows the user to set up multiple P/N Control schedules for specific N/H/A P/N's or A/C. With a prorated limit schedule set up, when the P/N S/N is installed on the N/H/A or A/C it will inherit and track the appropriate prorated limit schedule.

button allows the user to set up multiple P/N Control schedules for specific N/H/A P/N's or A/C. With a prorated limit schedule set up, when the P/N S/N is installed on the N/H/A or A/C it will inherit and track the appropriate prorated limit schedule.

A default P/N Control must be set up before prorated limit schedules can be applied; then, If a P/N S/N is installed on an N/H/A or A/C that is not set up with a prorated limit schedule, the P/N S/N will inherit the schedule set up in the default P/N Control.

Note: If the Prorating Limits checkbox is not selected in the P/N Master, Technical Engineering tab, the prorating button will appear as the A/C Type Series ![]() button. The same functionality is available, however the Prorated button is more so reserved for prorated limit schedules on engine components.

button. The same functionality is available, however the Prorated button is more so reserved for prorated limit schedules on engine components.

Set up P/N Control Prorated Limit Schedule:

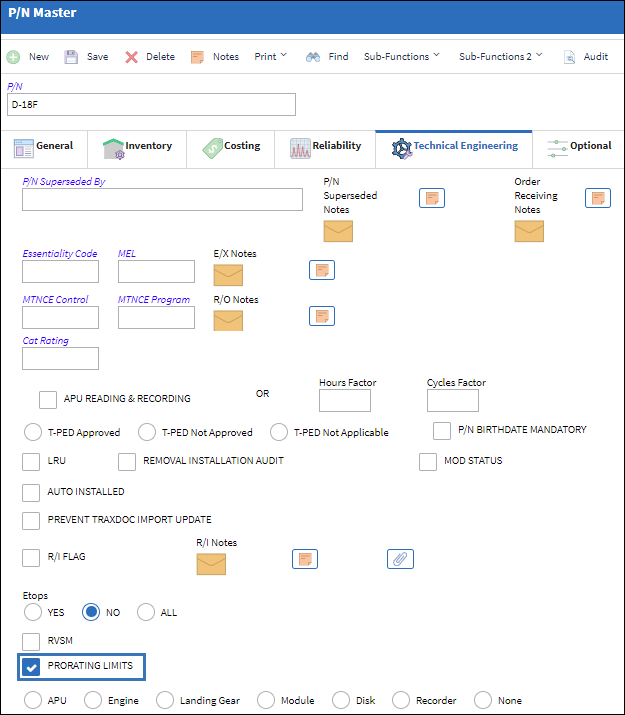

Select the Prorating Limits checkbox in the P/N Master, Technical Engineering tab.

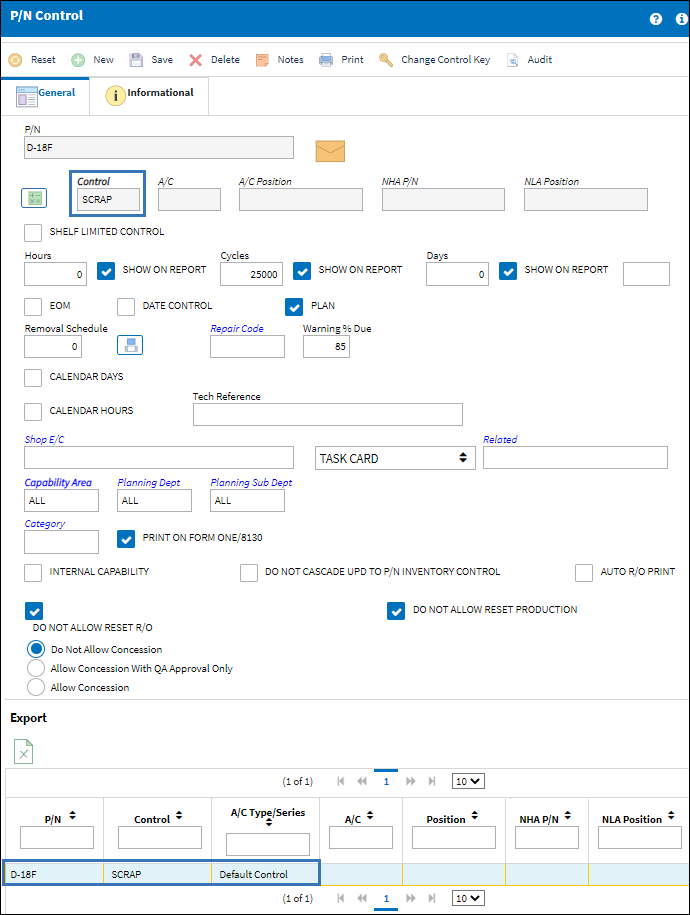

Create a default P/N Control without an A/C, A/C Position, or NHA P/N.

Select the Prorated ![]() button and the P/N Control Prorating Import/Update pop up will appear.

button and the P/N Control Prorating Import/Update pop up will appear.

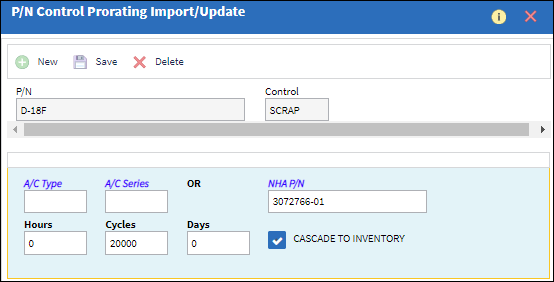

Enter the N/H/A P/N or A/C Type/Series that the prorated schedule is needed for and populate the prorated limit schedule.

Note: The P/N must exist as part of the N/H/A assembly or be effective to the A/C Type/Seires.

Note: If a prorated limit schedule for an A/C Type/Series is lower than the P/N Control's default schedule, a part that has accumulated flight times that exceed that A/C lower limit while installed on an aircraft with a greater limit, may be overdue when installed on the A/C with the lower limit. Therefore that part would be considered overflown for the lower limited A/C. (For example: the P/N Control's default is 4,000 hours, and the part was installed on a 5,000 hours prorated A/C. On the 5,000 hours A/C, the part flew 3,700 hours. If the part is removed and installed on an A/C that has a 3,500 hours prorated limit schedule, the part will be considered overflown for that aircraft.)

The following information/options are available in this window:

_____________________________________________________________________________________

A/C Type/Series

The Aircraft Type and Series/Fleet assignment.

NHA P/N

The part's Next Higher Assembly P/N (if applicable). If an N/H/A P/N is specified, the control will be applicable to the N/H/A P/N. All P/N Control schedules are action based. In other words, P/N schedules will not change seamlessly just because schedule criteria is met. There must be some transaction to generate the change in the P/N Control schedule. Examples of such actions are when a P/N is received, an A/C Position is changed, or when there is an A/C installation to trigger the schedule change against the part.

Hours/Cycles/Days

Prorated limit schedule for the A/C Type/Series or N/H/A P/N.

Cascade to Inventory checkbox

Select to apply the life limit schedule to all parts currently in service.

Note: Any parts currently installed on the A/C that exceed the new prorated limit schedule will be overdue.

_____________________________________________________________________________________

Select the Save ![]() button.

button.

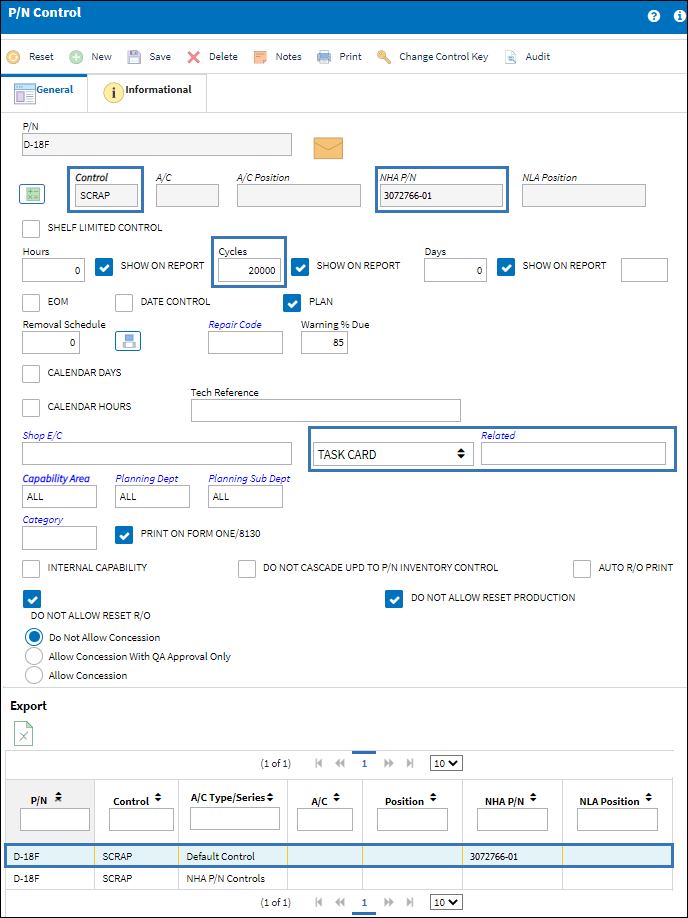

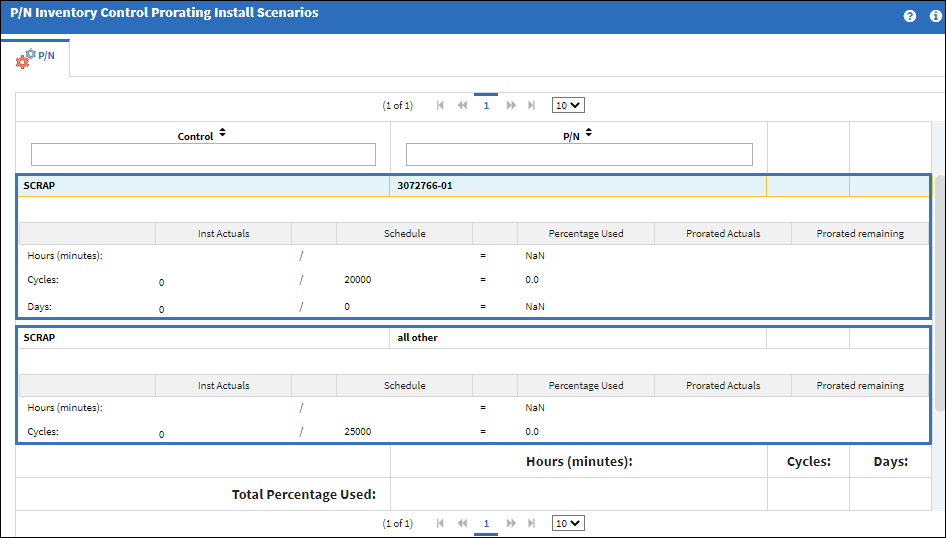

At the bottom of the P/N Control window, the P/N Control has duplicated for each N/H/A P/N, or A/C of the A/C Type/Series, that was specified in the P/N Control Prorating Import/Update pop up, and has inherited the prorated limit schedule.

Each P/N Control can be edited as required on an individual basis, modifying the schedule and entering the related Task Card or E/C.

For P/N S/Ns that are currently installed on a prorated N/H/A P/N or A/C, the P/N Inventory Control and planning forecast will track from the prorated limited schedule.

For additional information regarding the Prorated Actuals, refer to the Seamless Prorated Part Formula Used In Planning section of this manual.

From within the P/N Control details, select the Prorated ![]() button to view the prorating install scenarios.

button to view the prorating install scenarios.

Share

Share

Print

Print