Share

Share

Print

Print

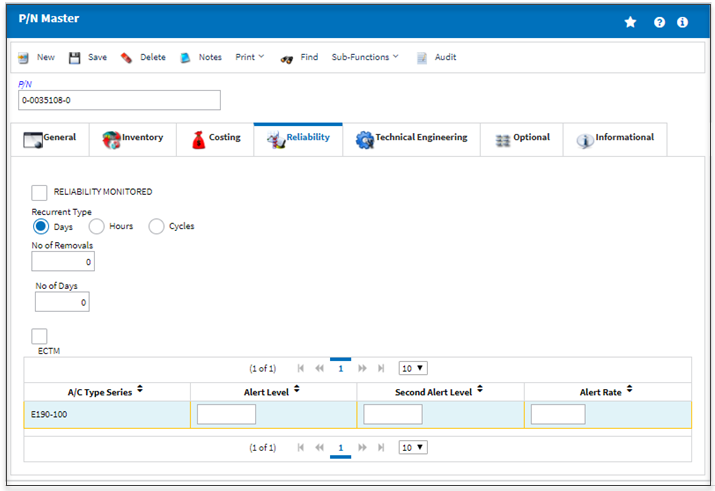

P/N Master, Reliability Tab

Alert levels can be set up for parts through the Reliability tab. These alert levels are used within the Reliability module of the system. The Reliability module is used to provide statistical data regarding the reliability of a specific aircraft or specific part numbers. Reliability reports can be produced as per company requirements and industry standards. Tracking of recurrent items can also be accomplished.

Recurrent unscheduled removals can be tracked by setting a tracking parameter. This parameter can be based on a Days, flight Hours, or flight Cycles range. For example, if the part is removed 2 times in a 20 days, a Recurrent Alert Item will be created in the Reliability module.

Only parts removed with the UnScheduled radio button selected in the A/C P/N Transaction window will affected Recurrent Unscheduled Removal Alerts. For more information refer to the

System Notifications can also be set up to alert specific users.

The following information/options are available in this window:

_____________________________________________________________________________________

Reliability Monitored checkbox

Select this checkbox to have the Reliability module provide statistical data (on reports and Recurrent Alert Items) regarding the reliability of this particular part. Reports can then be filtered to display only parts that are “Reliability Monitored.”

Recurrent Type (Recurrent Unscheduled Removal Alert) radio button

Select the Days, Hours, or Cycles radio button to indicate the parameters for the recurrent unscheduled removal alert. The following options are available:

Days - Recurrent Items will be based on the amount of Removals during the specified range of installed days. (For example, when the part is removed 2 times within a range of 10 installed days. The 2 removals would be specified in the Number of Removals field, the installed days range in the Number of Days field.)

Hours - Recurrent Items will be triggered based on the amount of Removals that occur within the range of specified installed Hours. (For example, when the part is removed 2 times within a range of 40 installed hours. The 2 removals would be specified in the Number of Removals field, the installed hours range in the Number of Hours field.)

Cycles - Recurrent Items will be triggered based on the amount of Removals that occur within the range of specified flight Cycles. (For example, when the part is removed 2 times within a range of 20 flight cycles. The 2 removals would be specified in the Number of Removals field, the flight cycles range in the Number of Cycles field.)

Number of Removals

Enter the number of removals that must occur (within the specified number of days in the Number of Days field) in order for the system to create and Alert for this part number.

Number of Days/Hours/Cycles

Enter the number of days/hour/cycles in which the specific number of removals must occur in order for a Recurrent Alert to be triggered. The Number of Removals field must occur in order for the system to create an Alert for this part number. This field changes per the radio button selected above for recurrent type (Number of Days, Number of Hours, or Number of Cycles).

ECTM checkbox

Check the Engine Conditioning Trend Monitoring checkbox to indicate that this part will be monitored appropriately via the Reliability module.

Chapter / Section / Paragraph

The ATA chapter/section/paragraph, as applicable.

A/C Type/Series

The Aircraft Type and Series/Fleet assignment.

Alert Level

Enter the actual alert level for the A/C Type/Series for the P/N. This may be provided by the A/C manufacturer or can be an organizational standard. P/N Reliability alert level is not required, but will allow alert levels to be shown on various prints. Make sure the Alert level can be applied to the A/C Type-Series indicated in preceding field.

Second Alert Level

Enter the second alert level for the A/C Type/Series for the P/N. P/N Reliability alert level is not required, but will allow alert levels to be shown on various prints. Make sure the Second Alert level can be applied to the A/C Type-Series indicated in preceding field.

Alert Rate

This field is used to define the failure rate alert level which will be used for calculating MTBF (Mean Time between Failures).

_____________________________________________________________________________________

Please refer to the Reliability manual for additional information regarding A/C and P/N reliability.

![]() Recurrent Item Alert (Reliability) Process

Recurrent Item Alert (Reliability) Process

Share

Share

Print

Print