Share

Share

Print

Print

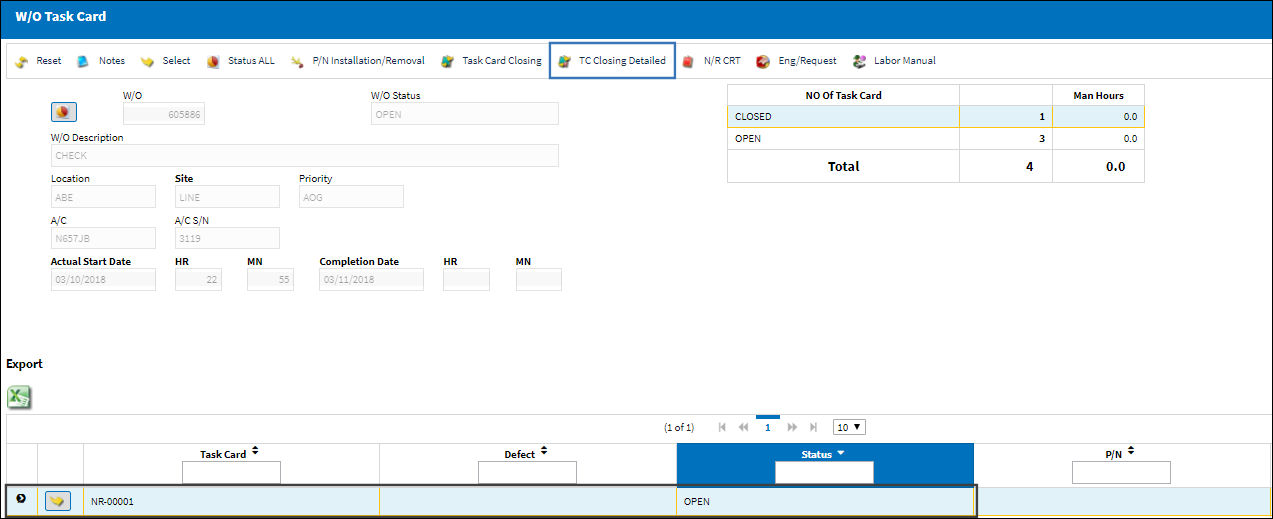

From the W/O Task Card window, choose an open Non-Routine Task Card.

Select the TC Closing Detailed ![]() button.

button.

The system displays the following window.

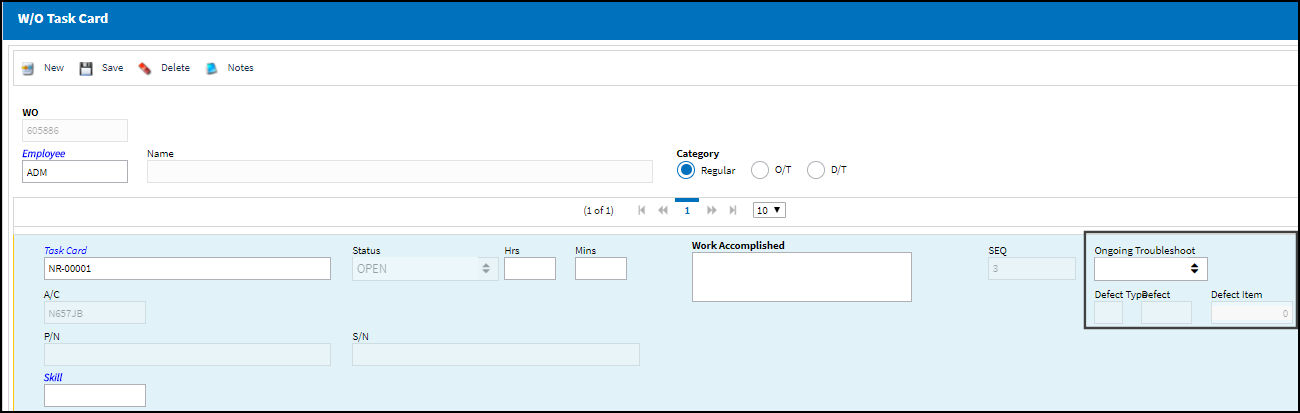

Populate all mandatory and desired information and save. Note that when closing a Non-Routine Task Card, the Ongoing Troubleshooting drop down and other Defect related fields appear.

The following information/options are available in this window:

_____________________________________________________________________________________

Work Order

The Work Order used to categorize, manage, and schedule work requirements for aircraft maintenance.

Employee

The employee who is closing the Task Card.

Regular / O/T (Over Time) / D/T (Double Time) radio buttons

The type of hourly work schedule being applied: Regular, Overtime, or D/T (Double time).

Task Card

The Task Card / Job Card that details the scheduled maintenance work.

Status

The current status of the Task Card. The status of the Task Card is helpful in determining the stage the Task Card is at with regard to it's completion. Ultimately, the completion of the Task Cards will result in the closing of the Work Order.

Hrs/Mins

The hour/minute the Task Card was closed.

Work Accomplished

The actual work that was accomplished against the W/O Task Card / Non-Routine Task Card.

SEQ

The Sequence Number. This number is generated from the number of times the Work Order (or Shop Work Order) Pack Print is printed and/or when the Sequence/Resequence buttons are selected through the Work Pack Print>Task Card button. (I.e., if there are ten Task Cards on a Work Order, and the Work Order has been printed twice from the Work Order Pack Print, for the first occurrence of the Work Order Pack Print, the Task Card would have a SEQ of one. For the second occurrence, the Task Card would have a SEQ number of 11.)

Note: When Production Switch ![]() ASSIGNSEQ is set to Yes, the Sequence Number may also be generated automatically by the system once the W/O Status changes from 'Generation' to 'Open'.

ASSIGNSEQ is set to Yes, the Sequence Number may also be generated automatically by the system once the W/O Status changes from 'Generation' to 'Open'.

Work Accomplished Status drop down

Select the status of the Work Accomplished. The Work Accomplished status is mandatory.

Note: This field only appears if a Non-Routine Task Card is being closed.

Ongoing Troubleshooting - For the Non-Routine Task Cards, the defect can be ongoing or resolved. When Ongoing Troubleshooting is selected, the Work Accomplished is transferred to the Defect Troubleshooting Tab. From the W/O Task Card window, select the Non-Routine Create ![]() button. The system displays the W/O Non-Routine Task Card window. Be sure the Hand

button. The system displays the W/O Non-Routine Task Card window. Be sure the Hand ![]() Pointer is pointing to the correct Task Card. Select the Create New Defect

Pointer is pointing to the correct Task Card. Select the Create New Defect ![]() button. From the Task Card Transfer To Defect Reports window select the Trouble Shooting tab. The Work Accomplished saved in the W/O Task Card window has been transferred to the Trouble Shooting Tab.

button. From the Task Card Transfer To Defect Reports window select the Trouble Shooting tab. The Work Accomplished saved in the W/O Task Card window has been transferred to the Trouble Shooting Tab.

Defect Resolved - If Defect Resolved is selected and the defect is closed, the text in the Work accomplished field is transferred to the Work Accomplished Tab in the Defect Report.

Defect

Enter the Defect Report, Type, and Item that is linked to the OnGoing Troubleshooting.

Note: This field only appears if a Non-Routine Task Card is being closed.

_____________________________________________________________________________________

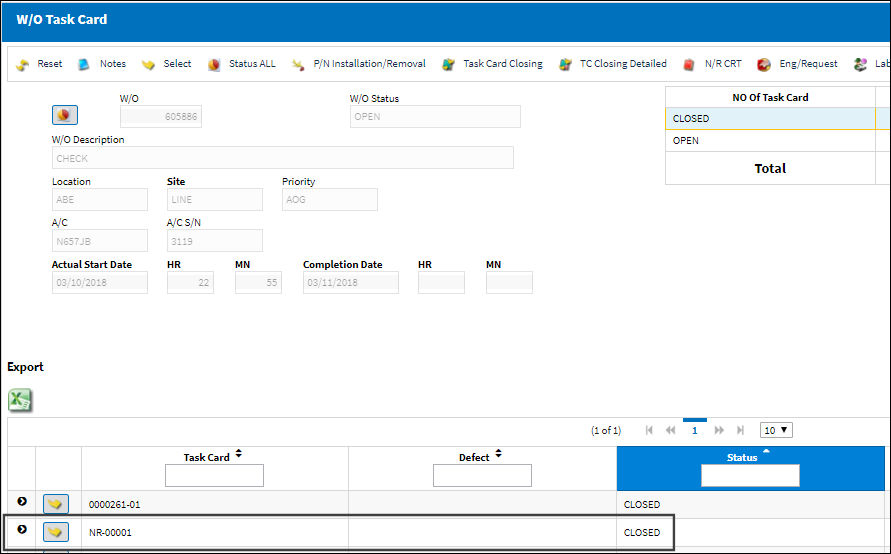

The Non-Routine Task Card goes to 'Closed' status as shown below:

Share

Share

Print

Print